Electrowetting Variable Focus Liquid Lens Containing Gradient Refractive Index Materials

A gradient refractive index and liquid lens technology, which is applied in the field of electrowetting variable focus liquid lenses, can solve the problems of difficult processing and poor sealing performance of diffractive lenses, and achieve the effects of easy processing accuracy, good sealing performance and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

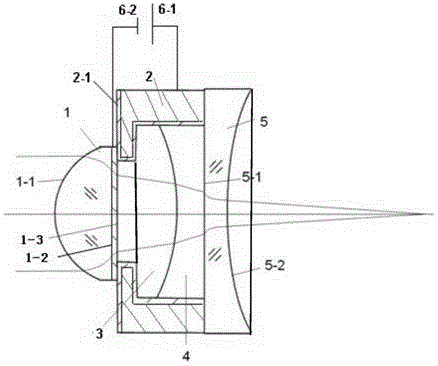

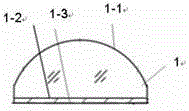

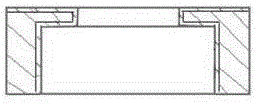

[0029] as figure 1 As shown, the preferred embodiment of the electrowetting variable focus liquid lens of the present invention includes a first lens 1 , a cavity 2 , a conductive liquid 3 , an insulating liquid 4 and a second lens 5 . The first lens 1 is a plano-convex lens with positive focal length made of graded index material (referring to figure 2 ), the front surface is a spherical surface 1-1, and the rear surface is a plane 1-2, on which an ITO conductive film 1-3 is plated by chemical vapor deposition, and the thickness of this embodiment is 125nm. Cavity 2 is an inverted U-shaped cylinder made of Kovar material (see image 3 ), the top surface has a through hole, and the inner surface and the top surface are coated with a hydrophobic dielectric film 2-1. In this embodiment, the hydrophobic dielectric film 2-1 is 16 μm t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com