Pipeline valve safety assessment method based on limit external load calculation

A load calculation and safety assessment technology, applied in calculation, special data processing applications, instruments, etc., can solve the problems of pipeline valve design rationality and quality reliability without pipeline valve safety assessment methods, so as to eliminate quality hidden dangers and shorten development Cycle time, effect of saving calculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

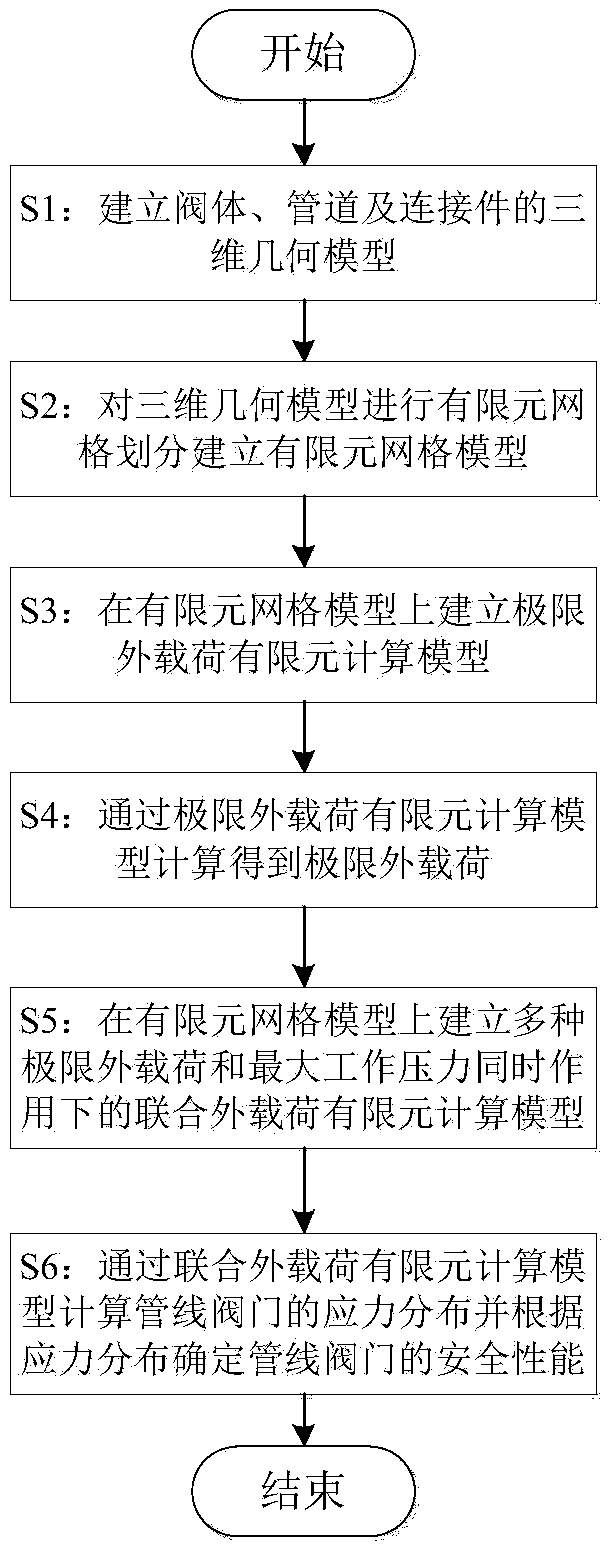

[0055] This embodiment provides a method for evaluating the safety of pipeline valves based on the calculation of limit external loads. The process is as follows figure 1 shown, including the following steps:

[0056] S1: Establish a three-dimensional geometric model of valve body 2, pipe 1 and connector 3

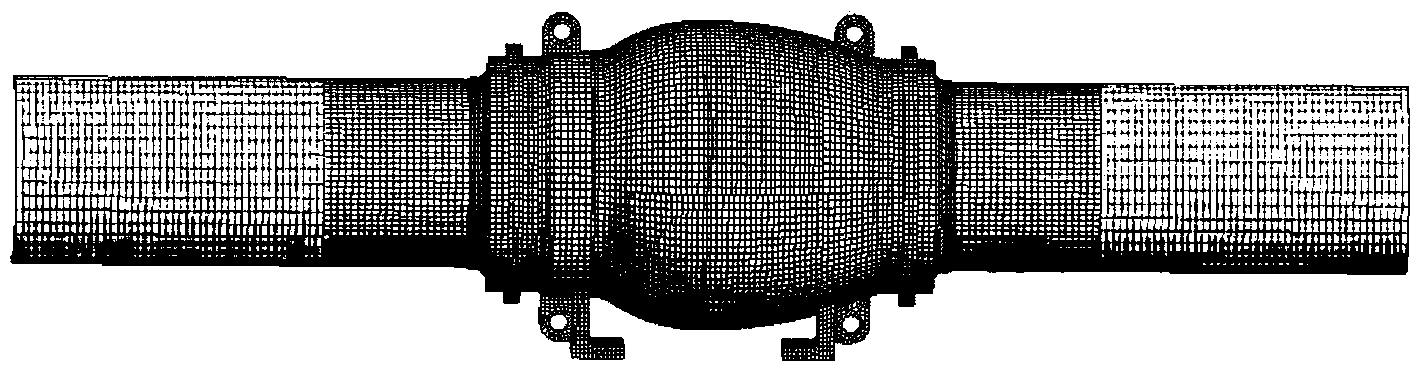

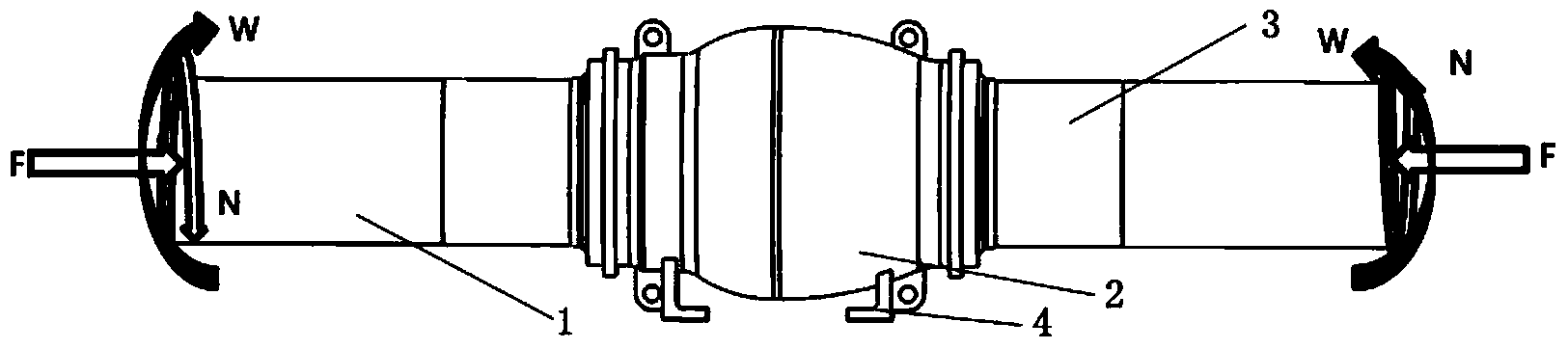

[0057] Use the 3D geometric modeling software SolidWorks to establish a 3D geometric model. The model components include valve body 2, connector 3 (welded sleeve) and pipe 1. The length of pipe 1 in the model is twice the diameter of the pipe. Since the model and boundary conditions are symmetrical Sex, just take 1 / 2 model. The maximum working pressure of the pipeline valve is P=15MPa, and the material parameters of the valve body 2, pipe 1 and connector 3 are listed below. The external load of the valve is shown as image 3 shown. By defining the symmetric boundary and using the 1 / 2 model, the calculation amount can be reduced by half, so that the calculation process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com