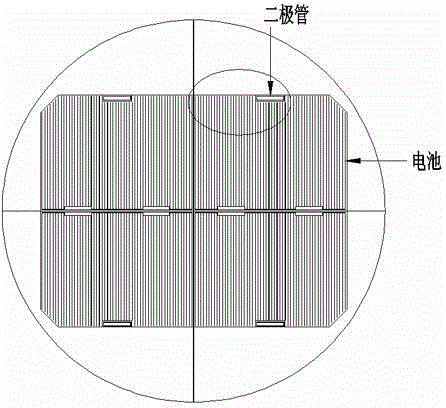

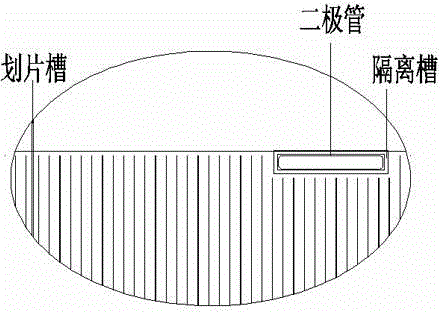

One-time corrosion process for multi-junction gallium arsenide solar batteries

A technology for solar cells and process methods, which is applied to circuits, photovoltaic power generation, electrical components, etc., can solve the problems of cumbersome wet etching steps of multi-junction gallium arsenide solar cells, and optimize the dicing process and reduce direction finding undercutting. , Improve the effect of corrosion accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

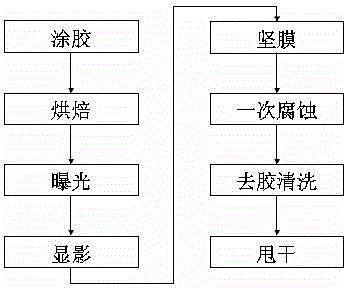

[0026] The multi-junction gallium arsenide solar cell primary corrosion process of the present invention is as follows: image 3 As shown, the process sequence in each process is: masking of photoresist coating, baking, exposure, development, film hardening, primary corrosion isolation groove / scribing groove, glue removal and cleaning, and drying.

[0027] The primary corrosion working principle of the multi-junction gallium arsenide solar cell of the present invention: nitric acid and hydrobromic acid will react to generate Br 2 and excess Br in the etchant - Complexation to form a more stable corrosion solution. Corrosion process through Br 2 The oxidative complexation of HBr corrodes GaInP, GaAs, Ge and other materials, and the corrosion rate can be adjusted by adding a buffer to the etching solution or changing the proportion of each component of the etching solution.

[0028] The specific process flow of the primary etching process for the multi-junction GaAs solar cel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com