Compatible with socket and cable output center-mounted power distribution pdu on both sides of the busbar

A busbar and cable technology, applied in the field of precision power distribution units, can solve the problems of affecting the work of the power supply object, low efficiency of manual production and assembly, low reliability, etc., to reduce the scope of multi-point failures and eliminate single-point failures. , the effect of improving the reliability of power distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

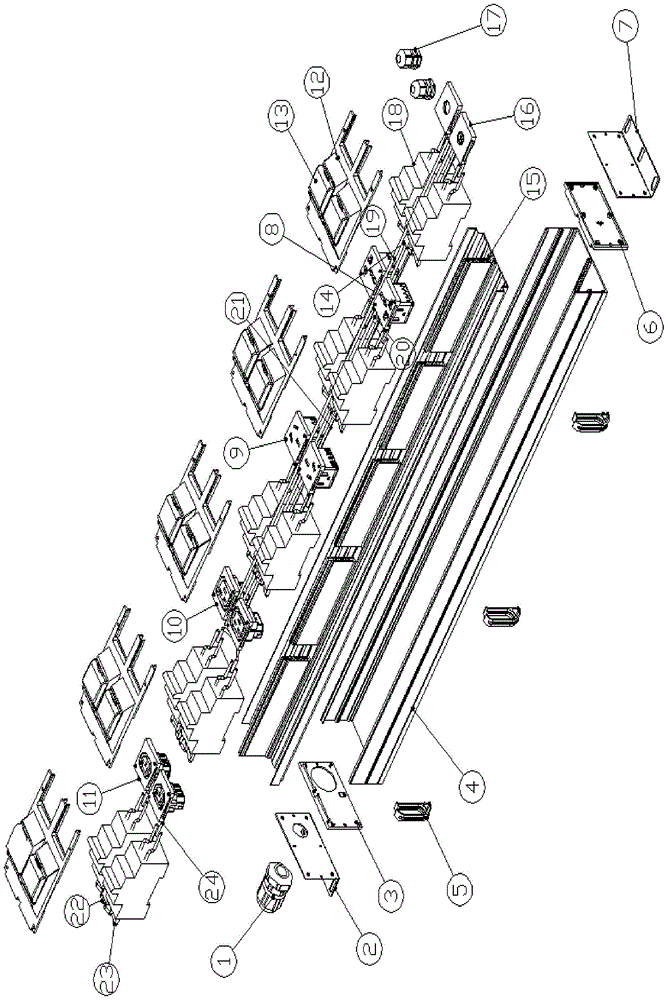

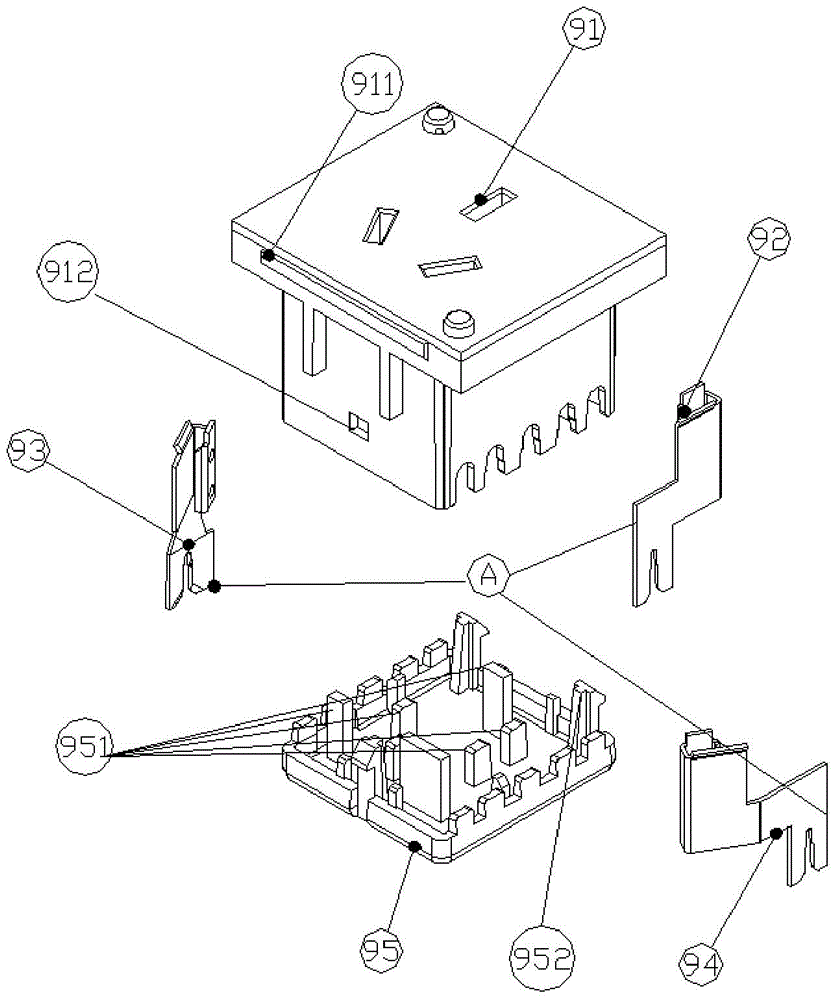

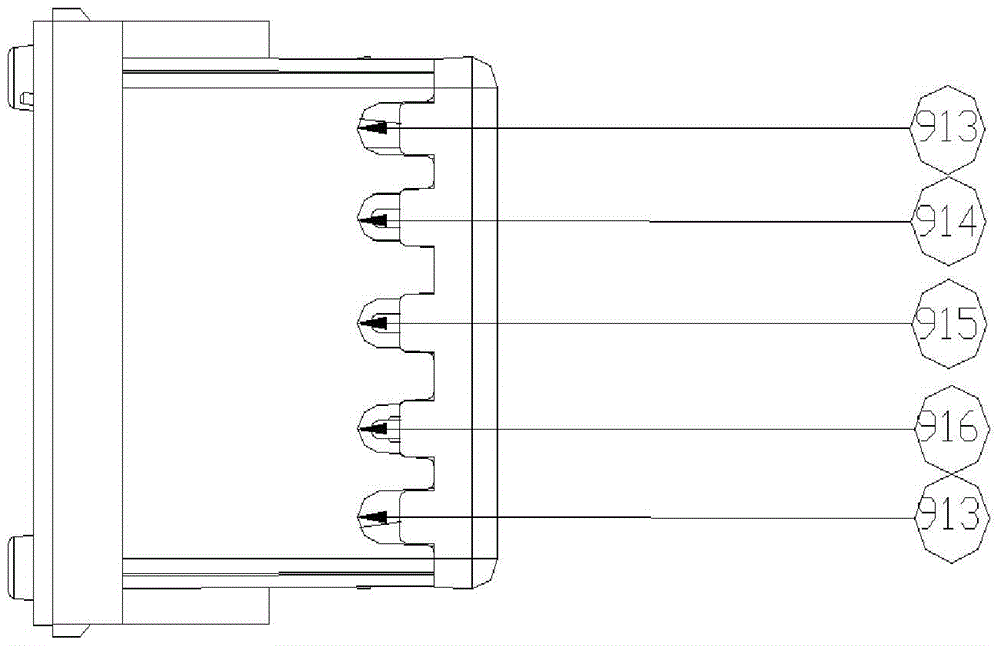

[0083] Such as figure 1As shown, the compatible socket and the cable output are centrally installed through the bus on both sides of the power distribution high-reliability PDU, including the end waterproof connector 1, the incoming line installation end plate 2, the incoming line insulation end plate 3, the shell 4, and the cable organizer 5 , insulating end plate 6, installation end plate 7, multiple socket modules, panel 12, circuit breaker protective cover 13, clip-on non-destructive terminal 14, bus support 15, terminal board 16, waterproof terminal block 17, circuit breaker 18. Busbar-N19, busbar-L20, busbar-PE21, branch line-N22, branch line-L23 and branch line-PE24; socket modules include universal socket module 8, GB-10A socket module 9, IEC- C19 socket module 10 and / or IEC-C13 socket module 11.

[0084] Each busbar is electrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com