Small-size, high-sensitivity and high signal-to-noise ratio MEMS (Micro-electromechanical Systems) silicon microphone

A high-sensitivity, silicon microphone technology, applied in electrostatic transducer microphones, sensors, electrical components, etc., can solve the problem of increasing the cavity volume of microphone devices, meet the trend and demand of circuit integration, and reduce module volume , the effect of increasing sensitivity and signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

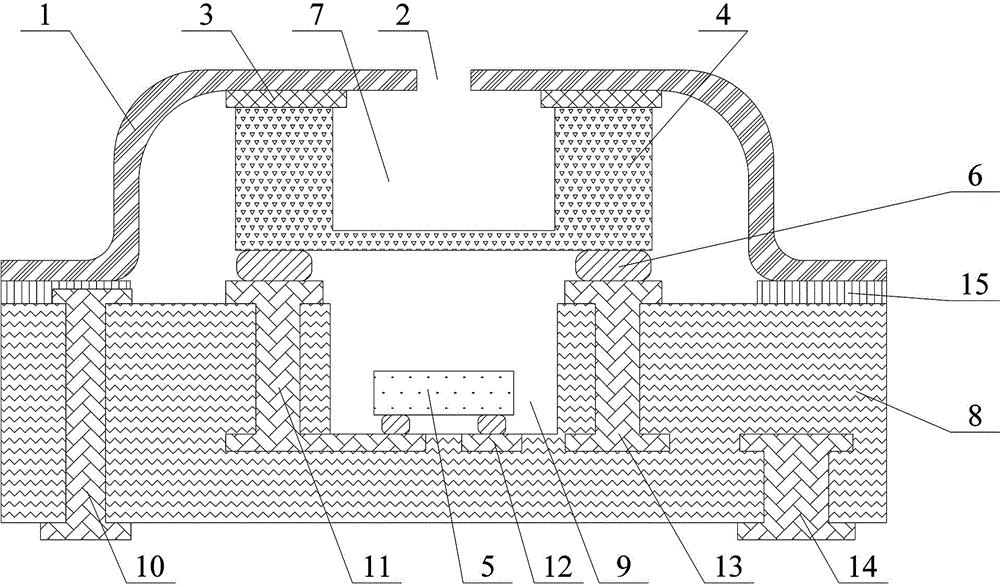

[0027] According to attached figure 1 , the product of the present invention includes a metal shell cover 1, a sound inlet hole 2, an insulating glue 3, a MEMS device 4, an ASIC device 5, a metal solder ball 6, a cavity 7 on the MEMS device and a PCB board 8, and the PCB board is provided with The groove 9 , the first metal wire 10 , the second metal wire 11 , the third metal wire 12 , the fourth metal wire 13 , the fifth metal wire 14 and the closed ring 15 formed by conductive glue.

[0028] The vertical flip-chip forward sound packaging method of the MEMS silicon microphone of the present invention includes a metal case cover 1, a MEMS device 2 placed in the metal case cover, and a groove that matches the cavity 7 on the MEMS device 2 9 of the PCB board 8 (the PCB board 8 adopts a three-layer PCB board) and the ASIC device 5 placed in the groove 9 of the PCB board 8 .

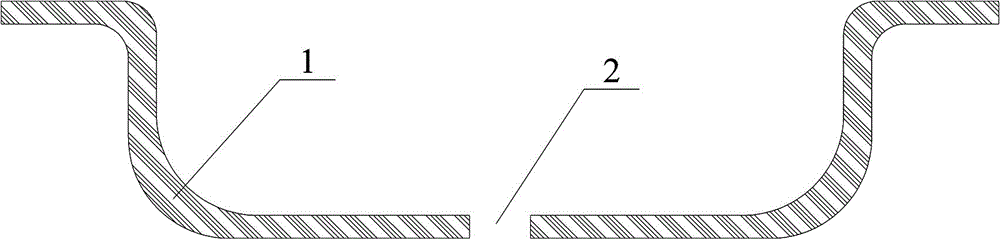

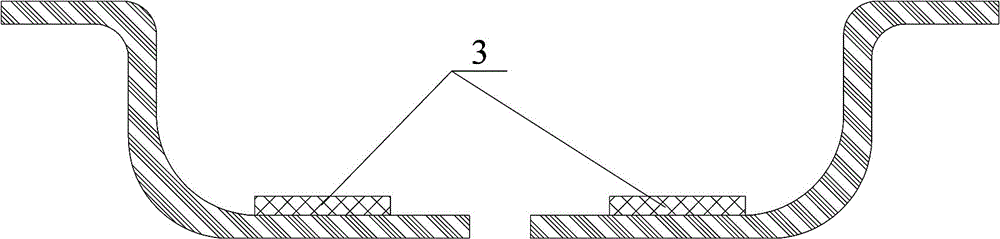

[0029] According to attached Figure 2-7 , the metal case cover 1 of the present invention is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com