Method and device for strong solid phase repair welding such as friction stir welding defects of storage tank

A technology of friction stir welding and welding defects, which is applied in the direction of welding equipment, non-electric welding equipment, household containers, etc., to achieve the effect of stabilizing the welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

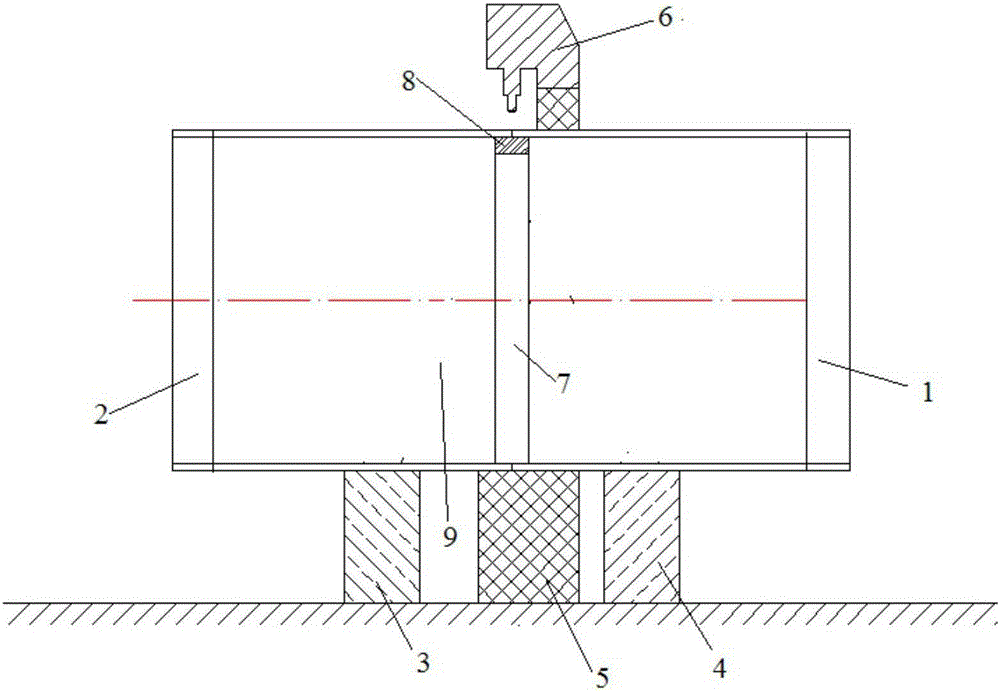

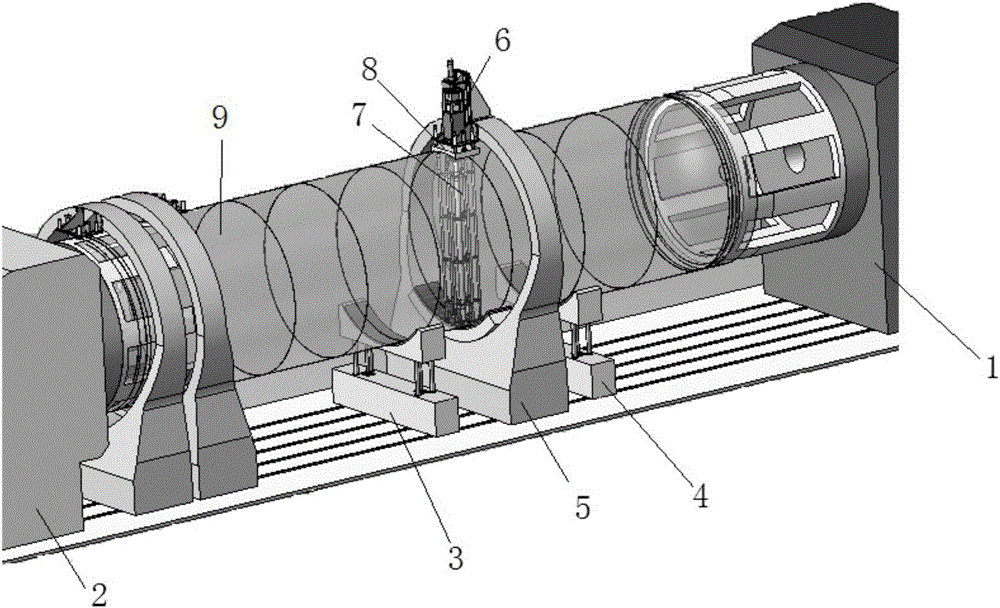

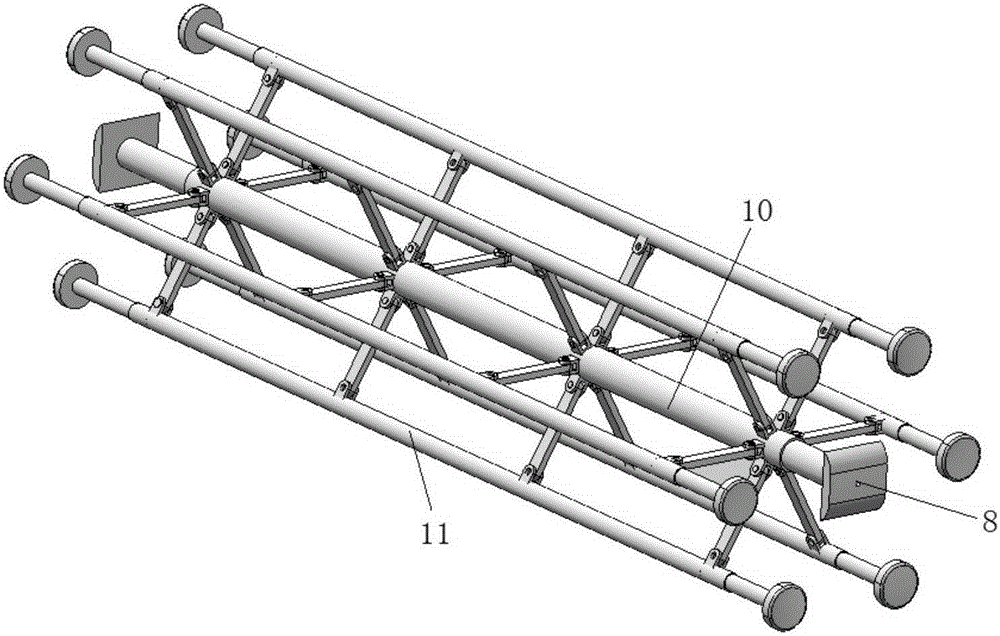

[0026] like figure 1 and figure 2 As shown, a device for strong solid phase repair welding such as tank friction stir welding defects according to the present invention includes a head box 1, a bed tail box 2, a tank support mechanism one 3, a tank support mechanism two 4, Hug ring 5, inner strut group 7.

[0027] Wherein, the bedside box 1, the ring 5 and the tail box 2 are arranged side by side, and the ring 5 is positioned between the head box 1 and the tail box 2, so that the two ends of the welded storage tank section are installed on the head box 1 and the tail box respectively. On the bed end box 2, the tank tube section 9 passes through the clasp 5; below the tank tube section 9, between the clasp 5 and the bedside box 1, a tank support mechanism 2 4 is set; below the tank tube section 9, A storage tank supporting mechanism-3 is arranged between the clasp 5 and the tail box 2 .

[0028] Fix the main machine 6 for repair welding directly above the ring 5, and place ...

Embodiment 2

[0033] According to the present invention, a method for repairing welding of strong solid phases such as tank friction stir welding defects using the repairing welding device described in Embodiment 1, the method includes the following steps:

[0034] (a) if figure 1 and figure 2 As shown, after finding that there is a welding defect in the friction stir welding assembly girth of the tank barrel section 9, the welded tank barrel section 9 is first installed between the head box 1 and the bed tail box 2; the tank barrel section 9 passes through Over the ring 5, and the welding defect of the storage tank section 9 is located at the ring 5; the repair welding host 6 is fixed directly above the ring 5.

[0035] (b) Install on repair welding host 6 Milling cutter, cut one at the position of the defective weld seam on the tank barrel section 9 Through holes, the inner strut group 7 is set inside the tank section 9 and at the position where there is a welding defect.

[0036] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com