Radiator assembly subpackage platform

A technology for radiators and condensers, which is applied in the field of automobile manufacturing, and can solve problems such as bumps or scratches on aluminum condensers and radiator fins, scrapping of condensers and radiators, and rising production costs, so as to facilitate replacement and maintenance , simple structure, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

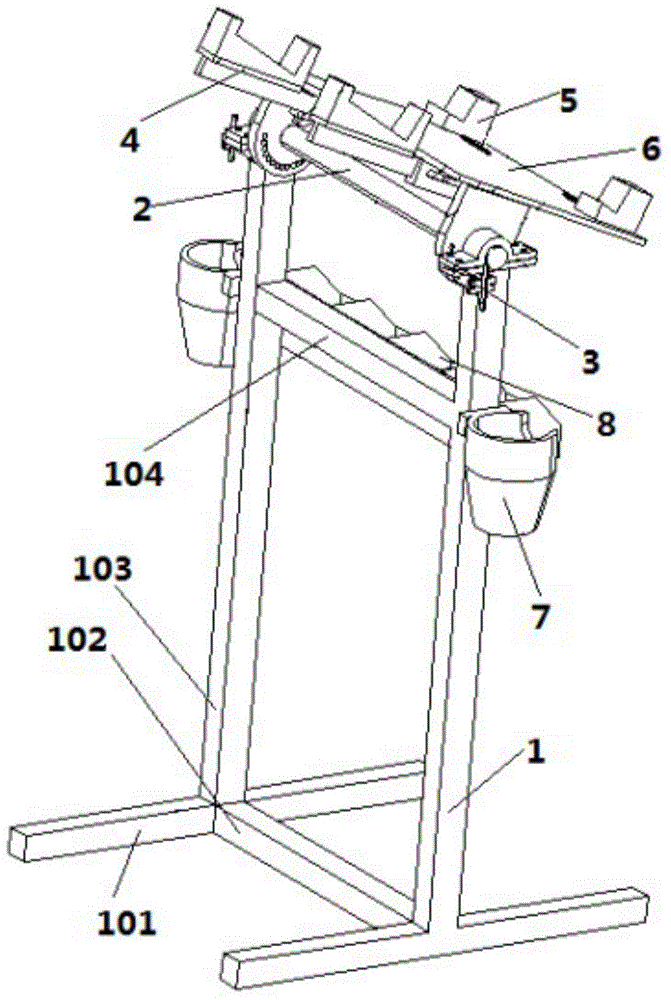

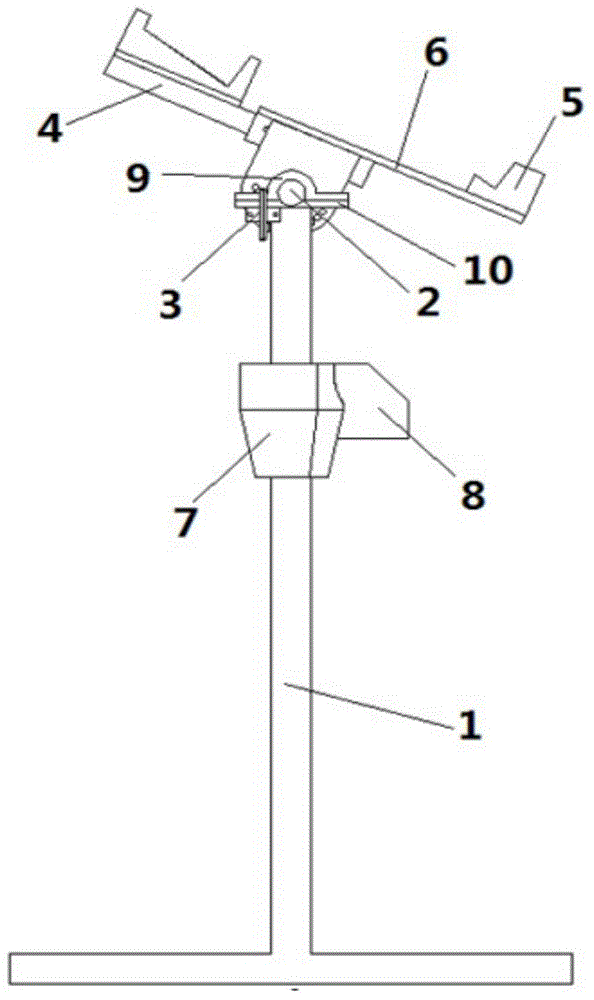

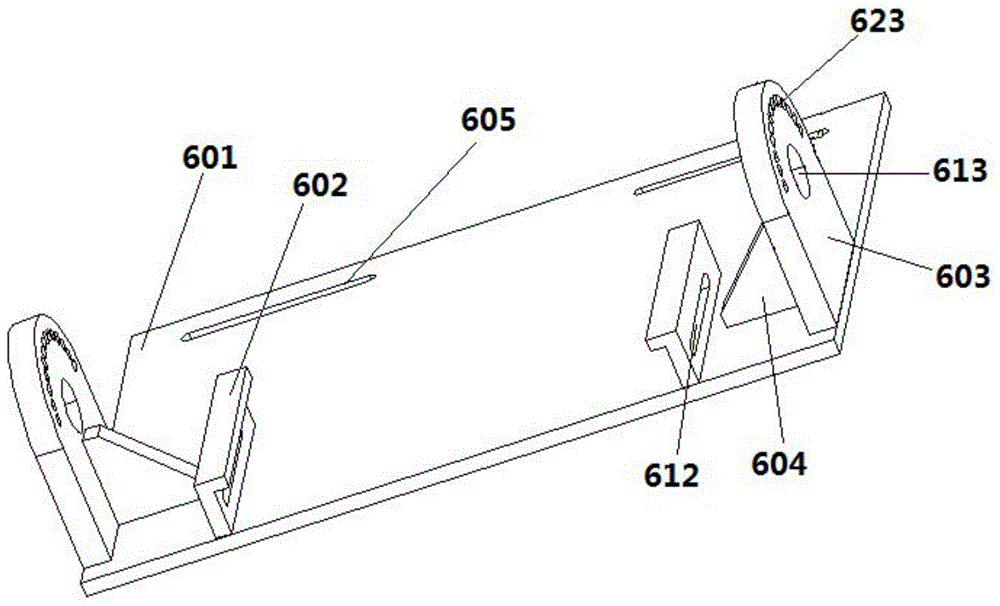

[0025] Radiator assembly platform of the present invention, as figure 1 , figure 2 As shown, it includes a supporting frame 1, a radiator supporting member 6 and a condenser limiting member 4. The radiator supporting member 6 is arranged on the supporting frame 1, and the condenser limiting member 4 is connected to the upper end of the radiator supporting member 6 and the installation position. corresponding position. The radiator supporting member 6 includes a supporting panel 601 and a rear limiting block 5 arranged at the lower end of the supporting panel 601 . When assembling, the radiator is placed on the support panel 601, and the lower end is limited by the rear limit block 5. The condenser is placed on the condenser limiting member 4, corresponding to the installation position of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com