A kind of preparation method of segmental synthesis crystal II type ammonium polyphosphate

A ammonium polyphosphate, segmented synthesis technology, applied in the direction of phosphate, phosphorus oxyacid, etc., can solve the problems of limitation, lower decorative performance, lower flame retardant performance, etc., achieve short reaction time, stable product quality, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

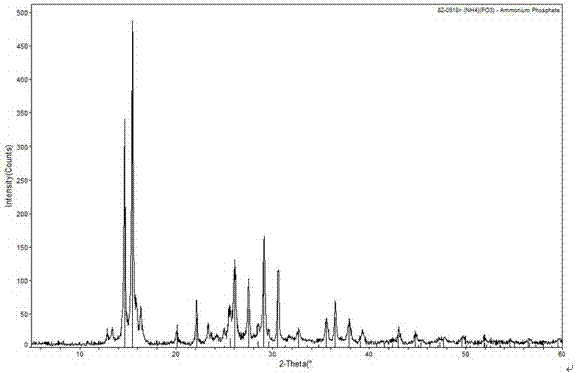

Image

Examples

Embodiment 1

[0022] Use industrial-grade phosphorus pentoxide as raw material, add urea for mixing, the mass ratio of industrial-grade phosphorus pentoxide and urea is 1:0.3, mix the two evenly and put them into the polymerization reactor, at 280℃~290℃ Under the temperature, keep the partial pressure of ammonia to react for 30 minutes to complete a stage of reaction.

[0023] After the above-mentioned first-stage reaction is completed, the first-stage reaction product is mixed with industrial-grade phosphorus pentoxide and ammonium dihydrogen phosphate, and the mass ratio of the three is 1:0.5:0.5. After the three are mixed evenly, they are added to a pressure polymerization kettle for two-stage reaction. The temperature of the reaction kettle is raised to 260°C, and the partial pressure of ammonia is maintained for 3 hours to obtain a crystalline type II ammonium polyphosphate product.

[0024] The ammonia partial pressure was maintained at 0.1 MPa and the flow rate was 1.0 L / min througho...

Embodiment 2

[0026] Use industrial-grade phosphorus pentoxide as raw material, add urea for mixing, the mass ratio of industrial-grade phosphorus pentoxide and urea is 1:0.5, mix the two evenly and put them into the polymerization reactor, at 220℃~230℃ Under the temperature, keep the partial pressure of ammonia to react for 120 minutes to complete a stage of reaction.

[0027] After the above-mentioned first-stage reaction is completed, the first-stage reaction product is mixed with industrial-grade phosphorus pentoxide and diammonium hydrogen phosphate, and the mass ratio of the three is 1:0.6:0.75. After the three are mixed evenly, they are added to a pressure polymerization kettle for two-stage reaction. The temperature of the reaction kettle is raised to 320°C, and the partial pressure of ammonia is maintained for 2 hours to obtain a crystalline type II ammonium polyphosphate product.

[0028] During the whole reaction process, the ammonia partial pressure was maintained at 0.07MPa, an...

Embodiment 3

[0030] Use industrial-grade phosphorus pentoxide as raw material, add urea for mixing, the mass ratio of industrial-grade phosphorus pentoxide and urea is 1:0.8, mix the two evenly and put them into the polymerization reactor, at 160℃~170℃ Under the temperature, keep the partial pressure of ammonia to react for 150 minutes to complete a stage of reaction.

[0031] After the above-mentioned first-stage reaction is completed, the first-stage reaction product is mixed with industrial-grade phosphorus pentoxide and ammonium dihydrogen phosphate, and the mass ratio of the three is 1:0.5:0.5. After the three are mixed evenly, they are added to a pressure polymerization kettle for two-stage reaction. The temperature of the reaction kettle is raised to 310°C, and the partial pressure of ammonia is maintained for 1.5 hours to obtain a crystalline type II ammonium polyphosphate product.

[0032] The ammonia partial pressure was maintained at 0.05MPa and the flow rate was 0.5L / min throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com