Method for manufacturing sandwich sheet and geocell manufactured through sandwich sheet

A technology of geocells and manufacturing methods, which is applied in the fields of soil protection, infrastructure engineering, construction, etc., and can solve problems such as large investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

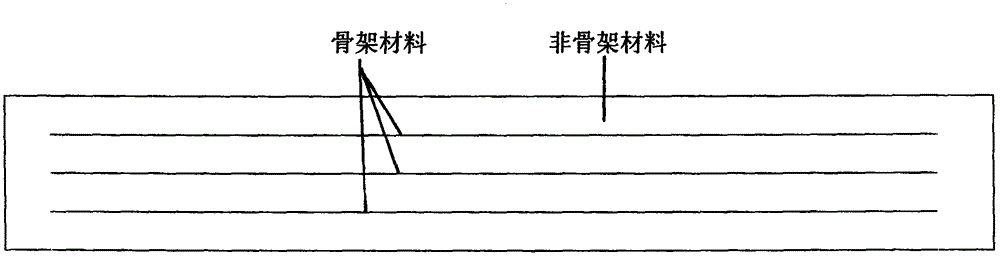

[0020] Embodiment 1: a kind of sandwich sheet with skeleton material discretely distributed [such as figure 1 Shown) the manufacturing method and the geocell made of it.

[0021] Choose three PE fishing net wires (about 0.09mm in diameter) as the skeleton material, or one PE fishing net wire, one PP fishing net wire and one PET filament (all about 0.09mm in diameter) as the skeleton material; The plastic particles recovered from plastic film are non-skeleton materials and are co-extruded at the same extrusion head (the temperature of the extruder and the head is controlled at 80-100°C, and the three skeleton materials are evenly distributed at equal distances.) Co-extrusion, two different strengths Sandwich sheets.

[0022] Choose above-mentioned a kind of sandwich sheet, intercept length 9 meters as one section, intercept 20 section sandwich sheets altogether; The longitudinal direction in each section sandwich sheet is divided into 12 equal parts, then the both sides of the...

Embodiment 2

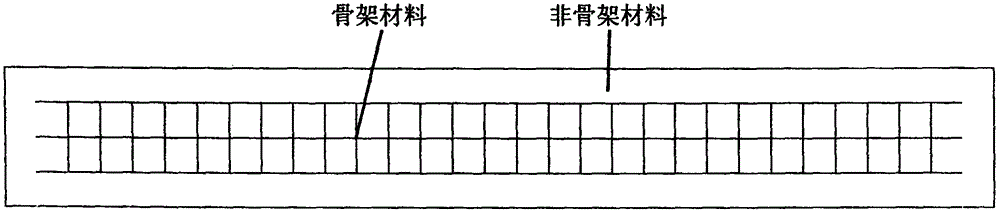

[0024] Embodiment two: a kind of sandwich sheet material (such as figure 2 Shown) the manufacturing method and the geocell made of it.

[0025] Weave one or several materials such as steel wire, glass fiber, carbon fiber, nylon wire, PET fiber wire or flat wire, PE fishing net wire or flat wire, PP fishing net wire or flat wire into a mesh structure as the skeleton material; Recycled plastic particles from waste agricultural mulching film are used as non-skeleton materials and heated and compounded on a composite machine to form a sandwich sheet with a network distribution of skeleton materials.

[0026] Alternatively, the network framework material is coated with a PVC paste resin, and then cured in a heating oven to obtain a sandwich sheet with a network distribution of the framework material.

[0027] A geocell is made by using the above-mentioned sandwich sheets distributed in a grid shape by the method of Example 1.

Embodiment 3

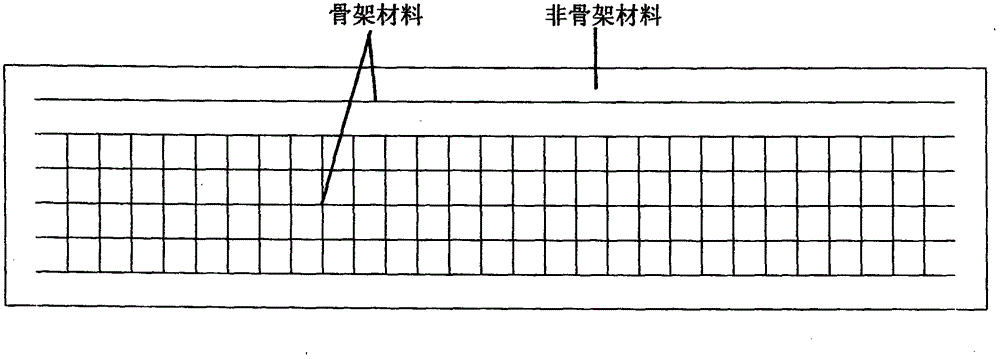

[0028] Embodiment three: a kind of sandwich sheet material (such as image 3 Shown) the manufacturing method and the geocell made of it.

[0029] Steel wire, glass fiber, carbon fiber, nylon wire, PET fiber wire or flat wire, PE fishing net wire or flat wire, PP fishing net wire or flat wire, etc. are used as discrete distribution skeleton materials; one or several of these materials are first woven into The mesh is used as a skeleton material for network distribution. Different combinations of these two types of skeleton materials are combined with materials with lower melting points, such as recycled plastic particles from waste agricultural mulch films or PVC paste resin, for thermal compounding or heating and curing, etc., to obtain sandwich sheets with discrete and network-like combinations of skeleton materials.

[0030] The above-mentioned sandwich sheet composed of skeleton materials discretely and reticularly distributed is made into a geocell by the method of Embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com