Hydraulic double acting rodless pump

An oil production pump, double-acting technology, applied in the field of hydraulic double-acting rodless oil production pump, can solve problems such as crash, pump body self-vibration, and the system cannot work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with specific examples.

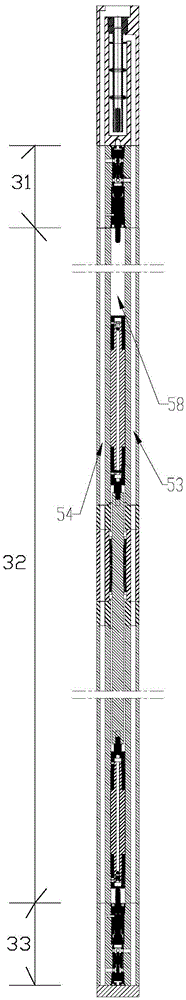

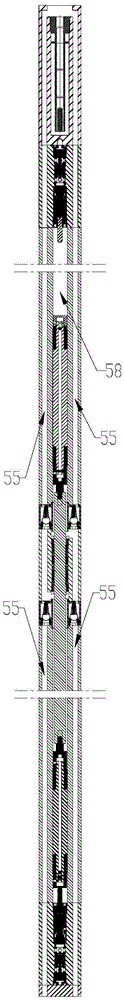

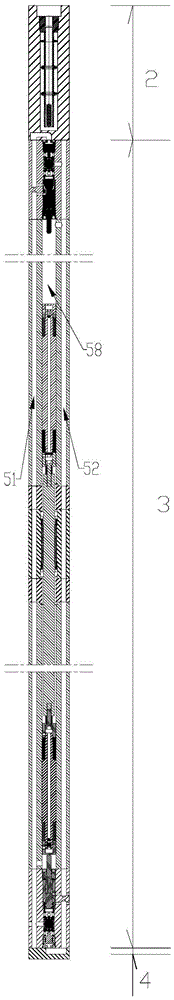

[0052] Such as Figure 1 to Figure 9 As shown, the hydraulic double-acting rodless oil recovery pump in this embodiment includes a cylindrical pump body 1 and supporting pipelines axially arranged in the pump body. Composed of tailstock 4;

[0053] The supporting pipeline includes an uplink signal pipeline 51, a downlink signal pipeline 52, a liquid inlet pipeline 53, a liquid return pipeline 54 and an oil pump pipeline 55, and a main pipeline 58 is arranged at the center of the functional section. All other pipelines are arranged around the main pipeline, that is, each pipeline is set at a phase angle of 60 degrees with the main pipeline as the axis; figure 1 As shown, the uplink signal pipeline 51 and the downlink signal pipeline 52 are arranged symmetrically on both sides of the main pipeline; after being separated by a phase angle of 60 degrees, the liquid inlet pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com