Intelligent wire rope vibration isolator

A steel wire rope and vibration isolator technology, applied in the field of vibration reduction and noise reduction, can solve problems such as inability to adapt to changes in excitation conditions, and achieve the effects of simple structure, improved vibration isolation performance, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

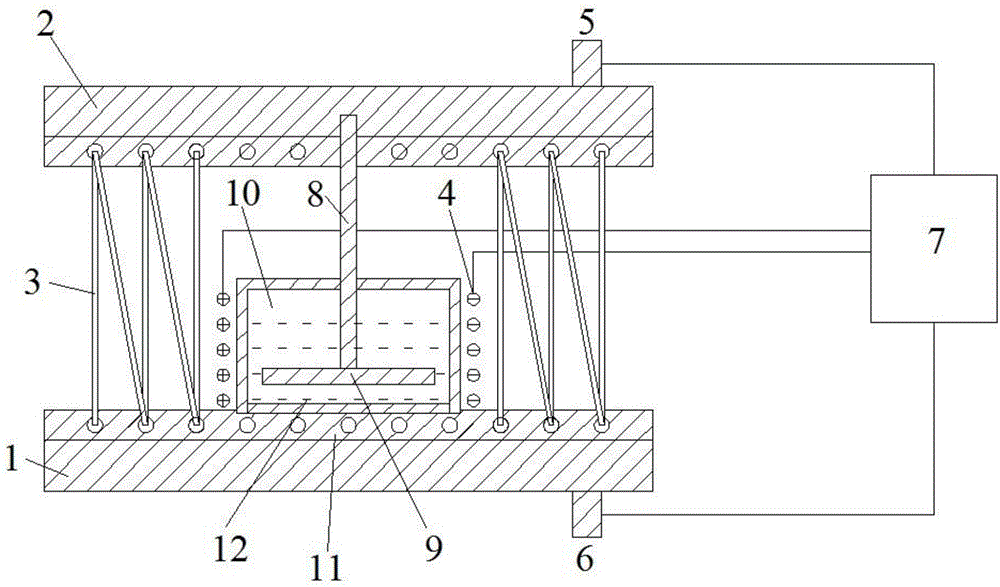

[0025] Such as figure 1 As shown, an intelligent steel wire rope vibration isolator includes an upper end plate 2 and a lower end plate 1 oppositely arranged, and a steel wire rope 3 arranged between the upper end plate 2 and the lower end plate 1, and also includes an upper end plate The working cylinder 10 between 2 and the lower end plate 1 contains a magnetorheological fluid 12, a coil 4 is wound on the outer surface of the cylinder 11, and an upper acceleration sensor 5 and a lower acceleration sensor 6 are respectively arranged at the upper end The board 2 and the lower end board 1 further include a single-chip controller 7 connected with the coil 4, the upper acceleration sensor 5 and the lower acceleration sensor 6 through signal lines.

[0026] The dimensions of the upper end plate 2 and the lower end plate 1 are 300 mm in length, 150 mm in width, and 50 mm in height. The inner diameter of the working cylinder 10 is 60 mm, and the outer diameter is 65 mm. The diameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com