Detecting tooling for vacuum and high-pressure leakproofness of brake caliper

A high-pressure seal and brake caliper technology, applied in the field of caliper detection, can solve problems such as difficulty in collecting full bubbles, difficulty in observation, and traffic accidents, so as to improve the efficiency of vacuum and high-pressure seal detection, eliminate leakage, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

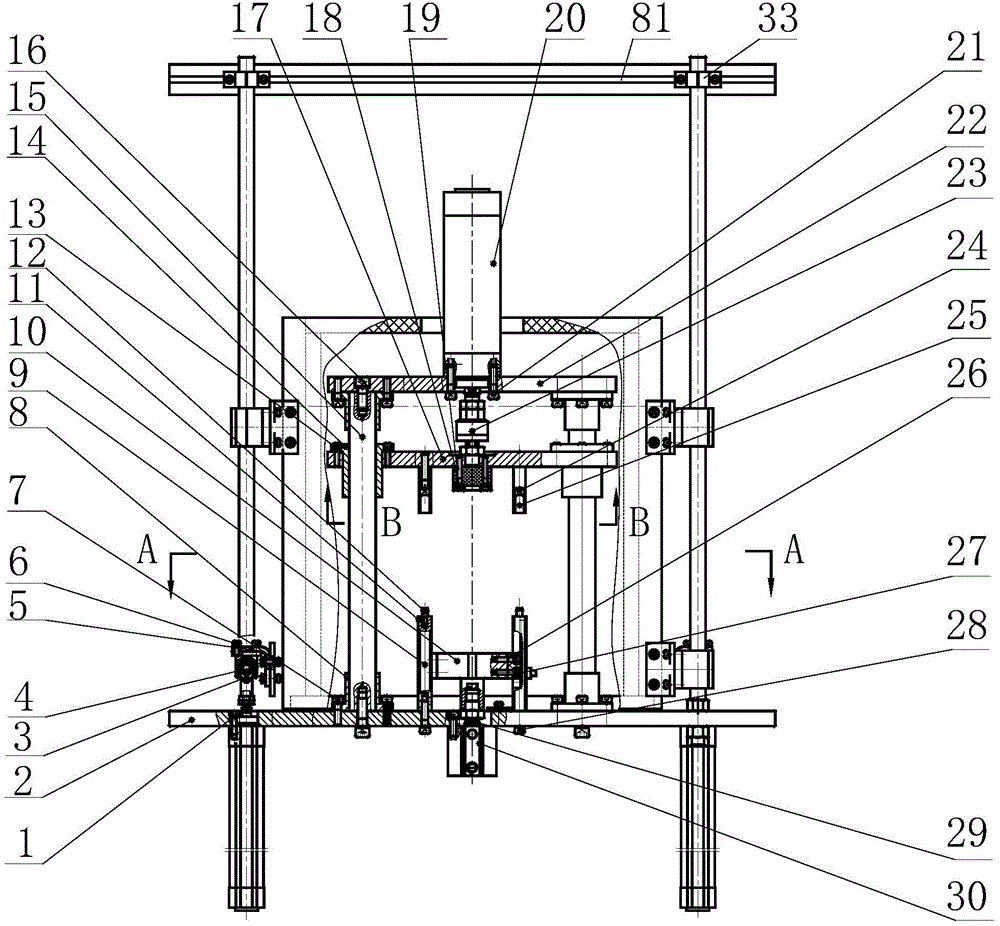

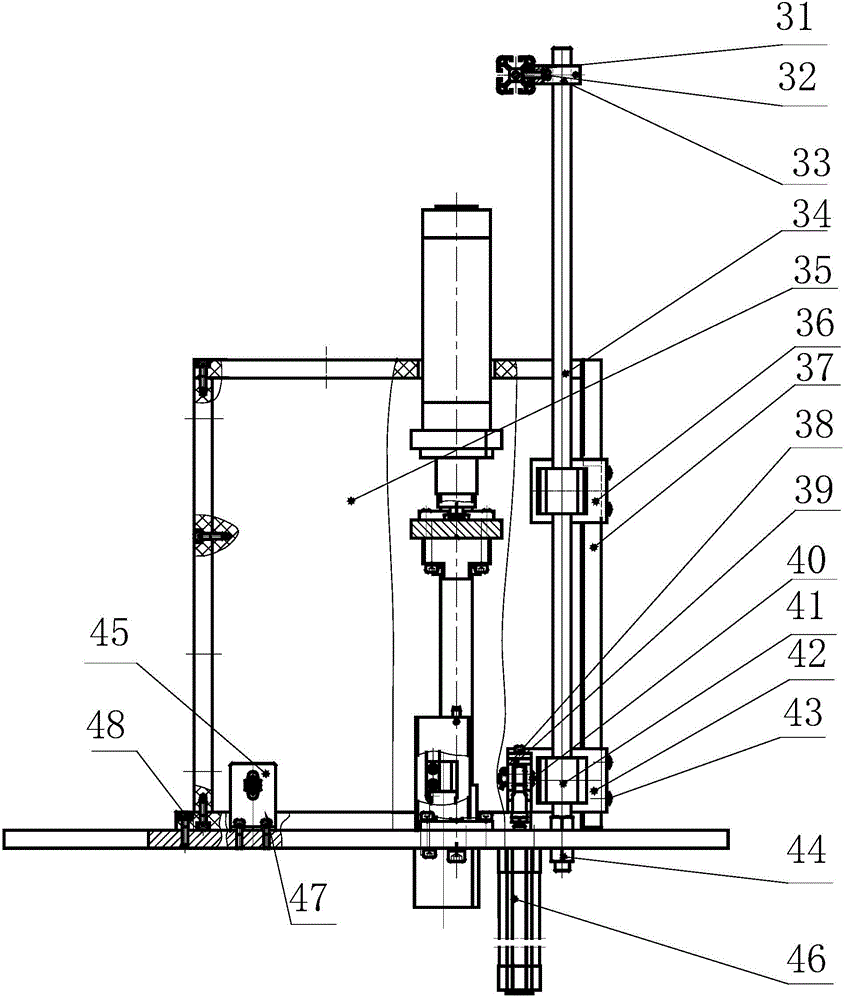

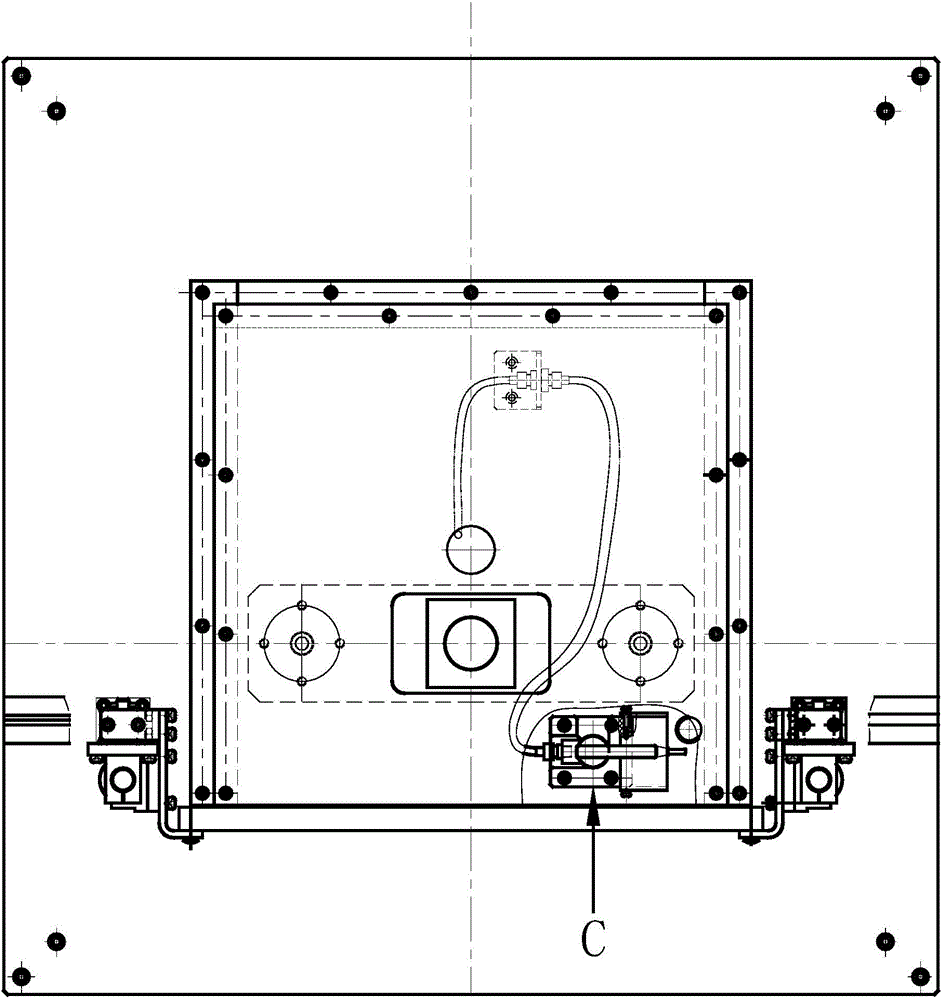

[0030] Such as Figure 1 to Figure 9 As shown, a vacuum and high-pressure sealing test tool for a brake caliper includes a workbench 2, the workbench 2 is a mounting surface, and the workbench 2 is vertically provided with two linear shafts - 15, two Two linear shafts 34, the lower ends of the two linear shafts 34 are fixed on the workbench 2 by hex nuts 44, the upper ends of the two linear shafts 34 are provided with SH linear shaft supports 33, the SH Aluminum alloy profile beams 81 are arranged between the linear shaft supports 33 , and the SH linear shaft supports 33 are fixed on the aluminum alloy profile beams 81 by T-shaped nuts 31 and screws 1 32 .

[0031]Two box bearings 41 are installed on each of the two linear shafts 34, and backing plates 49 are installed on the box beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com