Structural NVH (Noise Vibration and Harshness) analysis method for vibration interference abnormal noise based on modal frequency response

A modal frequency and analysis method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as shortening the development cycle, difficult to meet development requirements, inconsistent parts vibration modes, etc., to solve the problem of motion interference. noise, improve NVH performance, and shorten the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

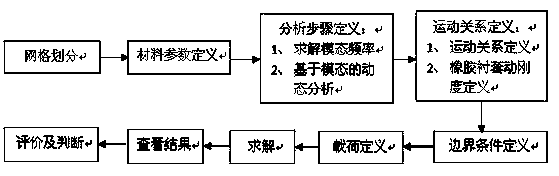

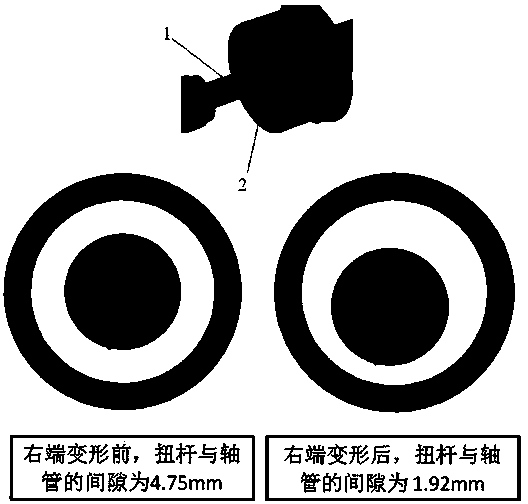

[0021] Example: see figure 1 , figure 2 .

[0022] A structural NVH analysis method based on vibration interference abnormal noise based on modal frequency response, the steps are as follows:

[0023] 1) According to the dynamic deformation of the gap when the two structural parts are connected by rubber bushings, CAE software is used for analysis. The first is the collection of rubber bushing parameters, that is, the dynamic stiffness curves of the bushing in three directions (X, Y, Z directions). If there is no dynamic stiffness curve, the dynamic stiffness values of the bushing in three directions must be measured through tests;

[0024] 2) Collection of basic parameters of structural components, including geometric dimensions, material parameters, and 3D models of shaft tubes, shaft rods, mounting brackets, and bases;

[0025] 3) Establish a finite element mesh model of the mechanism in the commercial software Hypermesh according to the three-dimensional model. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com