LED (light emitting diode) epitaxial layer structure and growth method thereof

A technology of epitaxial structure and growth method, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of LED device luminous efficiency, low carrier recombination efficiency, large lattice mismatch, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

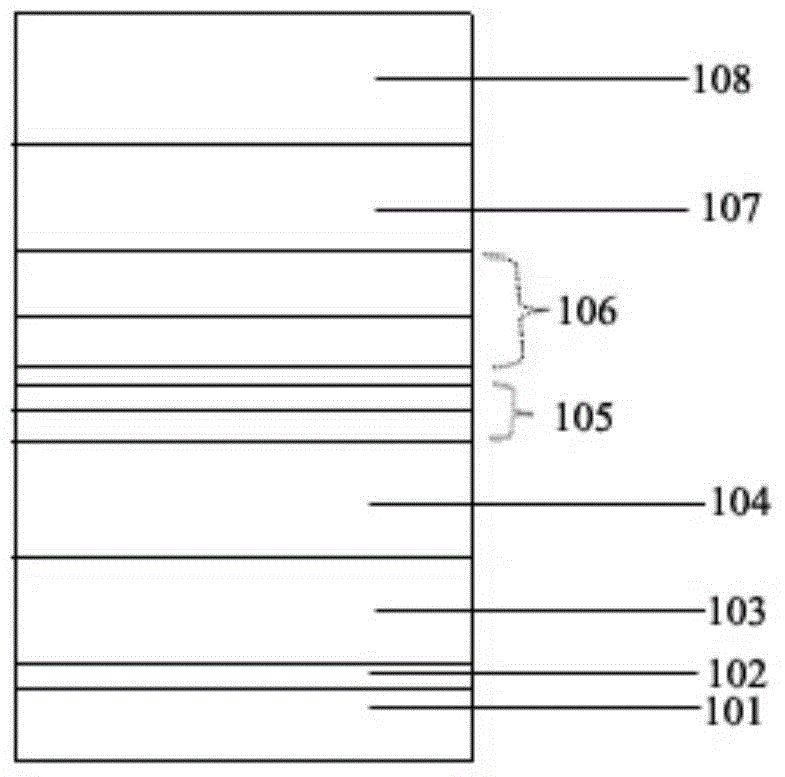

[0041] Such as figure 1 As shown, this embodiment provides an LED epitaxial structure, which includes sequentially from bottom to top:

[0042] A sapphire substrate 101, the sapphire substrate in this embodiment is a C-Plane sapphire substrate. However, it should be noted that the present invention does not limit the type and parameters of the sapphire substrate provided, such as thickness, diameter, crystal orientation, warpage, etc., and the specific parameters are determined according to specific design requirements.

[0043] A low-temperature buffer layer 102 located on the sapphire substrate 101;

[0044] a high-temperature GaN layer 103 located on the low-temperature buffer layer 102;

[0045] a high-temperature N-type GaN layer 104 located on the high-temperature GaN layer 103;

[0046] The transition layer 105 is located on the high-temperature N-type GaN layer 104, wherein the transition layer 105 is a transition layer in which Si3N4 / GaN superlattice layers and und...

Embodiment 2

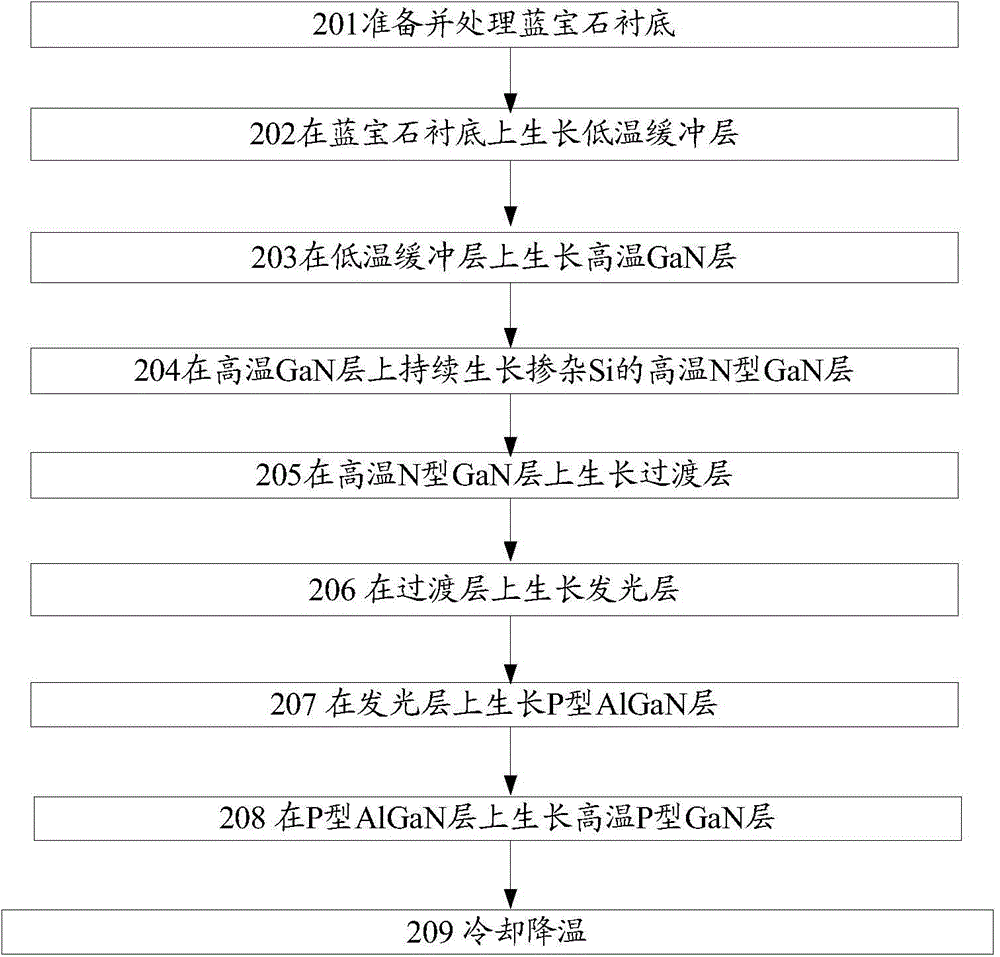

[0064] In this embodiment, the LED epitaxial structure is grown according to the following steps:

[0065] 1) Treat the sapphire substrate at 1100°C for 8 minutes under a hydrogen atmosphere with the reaction chamber pressure maintained at 100mbar;

[0066] 2) Lower the temperature to 600°C, maintain the pressure of the reaction chamber at 500mbar, and grow a low-temperature buffer layer GaN with a thickness of 35nm on the sapphire substrate;

[0067] 3) Raise the temperature to 1100°C, maintain the pressure of the reaction chamber at 250mbar, and continue to grow a 3μm undoped GaN layer;

[0068] 4) The temperature is 1100°C, the pressure is 300mbar, 250sccm TMGa, 60000sccmNH3 and 30sccmSiH4 are introduced, the growth time is 2000s, and the N-type GaN layer doped with Si is continuously grown, and the Si doping concentration is 7×10 18 , the total thickness is controlled at 3 μm;

[0069] 5) Lower the temperature to 800°C, maintain the pressure in the reaction chamber at 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com