High-purity ulipristal acetate

A high-purity technology of ulipristal acetate, applied in the field of high-purity ulipristal acetate compounds, can solve problems such as failure to prepare a single crystal form A crystal product of ulipristal acetate, and achieve high crystal yield , Simple operation, stable process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

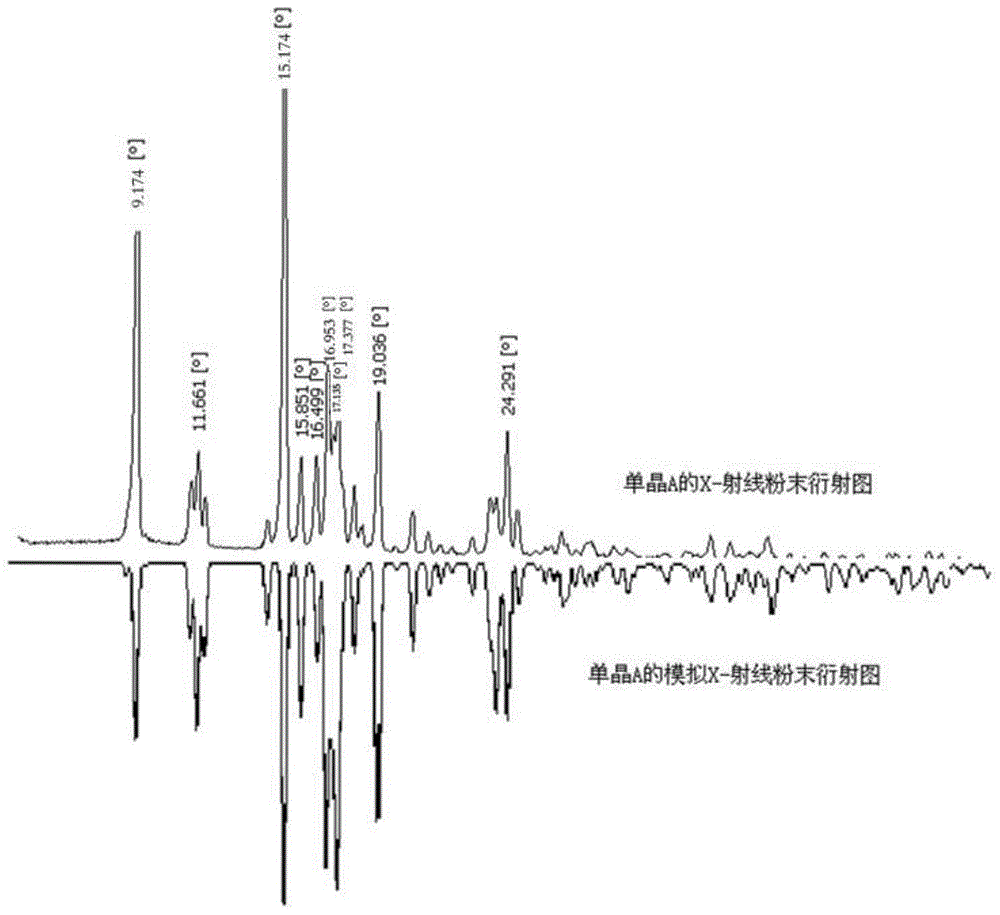

[0065] Preparation of single crystal A:

[0066] Ulipristal acetate is dissolved in methanol aqueous solution, and the solid is slowly volatilized at rest, and the large particle solid is taken as single crystal A. In this operation mode, single crystals of milligram level can be obtained each time.

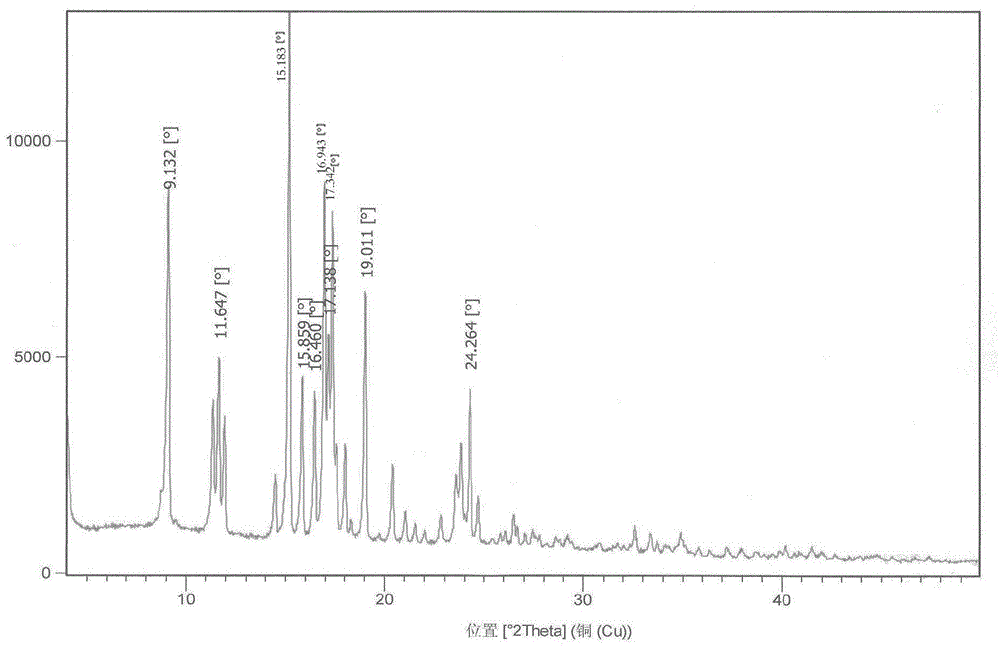

[0067] Preparation of crystal type A seed crystals:

[0068] Ulipristal acetate was added to 50-80% methanol aqueous solution, heated to reflux to dissolve, cooled by adding single crystal A to induce, slowly cooling down to gradually precipitate crystals, and the obtained crystals were used as crystal type A seed crystals. In this operation mode, gram-level seeds can be obtained every time.

Embodiment 1A

[0069] Example 1A Preparation of Crystal Form Ulipristal Acetate

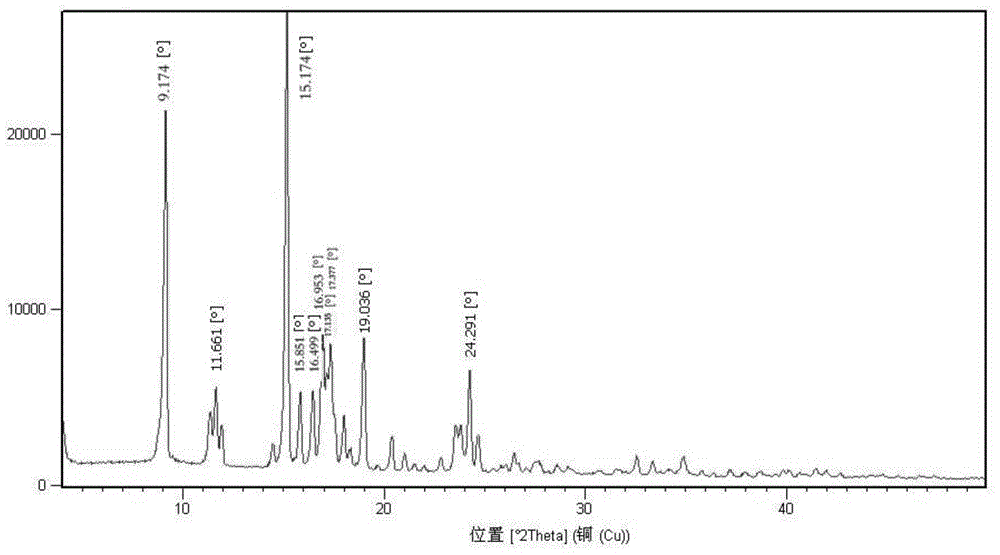

[0070] Take 8L prepared 30% (V Ethanol :V water =30:70) Ethanol aqueous solution, add 200g crude ulipristal acetate under stirring, heat up to reflux to dissolve, after dissolving, filter to remove mechanical impurities, the filtrate will continue to heat up to fully dissolved, cool to 50℃, add seed crystals under stirring 8g. Slowly cool down and gradually precipitate crystals, continue to cool to 0~5℃, filter, and dry under vacuum at 40~50℃ to obtain 160g of ulipristal acetate. The content of ulipristal acetate measured by HPLC is 99.85%, the largest single impurity The content is 0.05%. After X-ray powder diffraction test (using Cu-K radiation), the X-ray powder diffraction spectrum is as follows Picture 9 As shown, the diffraction data is shown in Table 4 below.

[0071] Table 4 X-ray powder diffraction data of crystalline form A ulipristal acetate prepared in Example 1

[0072]

Embodiment 2A

[0073] Example 2A Preparation of Crystal Form Ulipristal Acetate

[0074] Take 10L prepared 60% (V Ethanol :V Methanol :V water =40:20:40) Alcohol aqueous solution, add 400g crude ulipristal acetate under stirring, heat up to reflux to dissolve, filter to remove mechanical impurities after dissolving, continue to heat up the filtrate to fully dissolved, cool to 60°C, add under stirring Seed crystal 10g. Slowly lower the temperature and gradually precipitate crystals, continue to lower the temperature to 0~5℃, filter, and dry under vacuum at 40~50℃ to obtain 310g of ulipristal acetate. The X-ray powder diffraction test shows that Picture 9 Shown are consistent X-ray powder diffraction patterns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com