Pipeline thermal insulation device

A technology of thermal insulation device and pipeline, applied in thermal insulation, pipeline protection, pipeline protection through thermal insulation, etc., can solve the problems of poor thermal insulation effect, easy to rust, laborious and time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

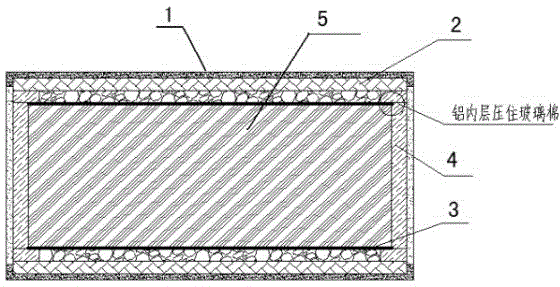

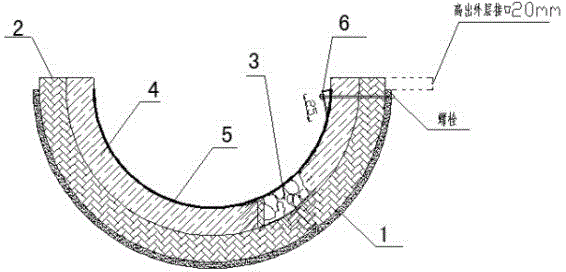

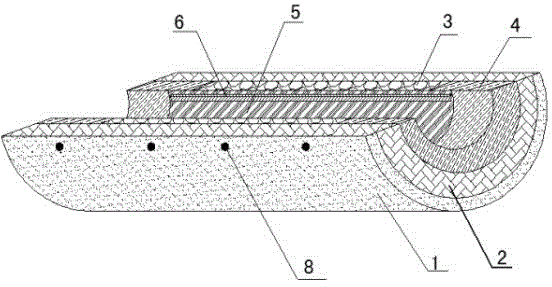

[0022] The present invention will be described in further detail below with reference to the accompanying drawings.

[0023] see figure 1 , 2 , 3, a pipeline heat preservation device, including a WK shell 1, the shell 1 is made of plastic steel; the shell 1 is provided with an aluminum silicate insulation cotton layer 2, and the aluminum silicate salt insulation cotton layer 2 is provided with silicic acid Aluminum thermal insulation cotton layer 3, glass wool 4 is arranged at both ends of the aluminum silicate thermal insulation cotton layer 3, an aluminum inner layer 5 is arranged on the aluminum silicate thermal insulation cotton layer 3, and hemming strips 6 are arranged inside the aluminum inner layer 5, The hemming strip 6 and the shell 1 are fixed by bolts, and the length of the bolts is greater than the thickness of the present invention by 5mm. The aluminum inner layer 5 covers all the aluminum silicate insulation wool layer 3 and the glass wool 4 and extrudes them ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com