Air-conditioning refrigerant pipe protection casing

A technology of refrigerant pipes and protective sleeves, applied in the direction of pipeline layout, etc., can solve the problems of high pressure on refrigerant pipes, long pipes, easy damage and rupture of refrigerant pipes, etc., and achieve good flexibility, wear resistance, antistatic and anti-ultraviolet performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

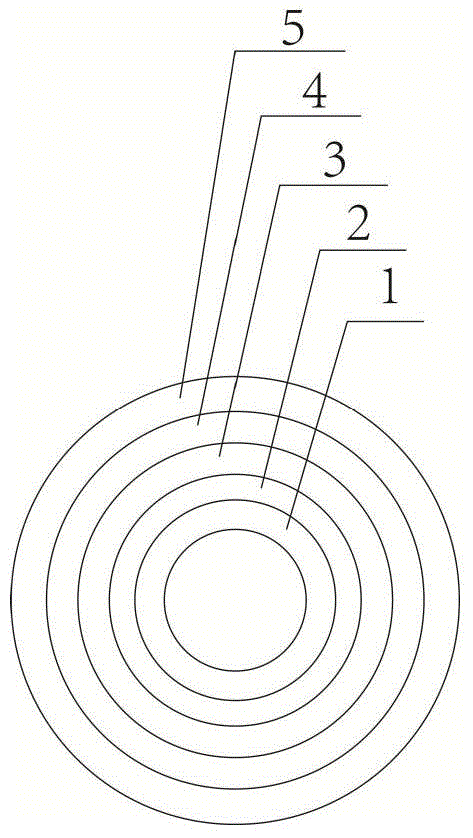

[0011] Such as figure 1 As shown, an air-conditioning refrigerant pipe protection device includes: an elastic layer 1, an insulating layer 2, an electrostatic shielding layer 3, an anti-oxidation layer 4, and a snakeskin braided layer 5, and the elastic layer 1 and the insulating layer 2 are sequentially arranged from the inside to the outside. , electrostatic shielding layer 3, anti-oxidation layer 4, snakeskin braided layer 5, snakeskin braided layer 5 has good flexibility, corrosion resistance, high temperature resistance, wear resistance, tensile resistance, and can well protect the refrigerant pipe Not affected by external factors, the wear-resistant and antistatic properties of the elastic layer 1, insulation layer 2, electrostatic shielding layer 3, and anti-oxidation layer 4 can protect the refrigerant pipes in various harsh environments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com