Sintering molding device and method for selective laser of rare earth permanent magnet device

A technology of laser selective sintering and rare earth permanent magnets, which is applied in the manufacture of electrical components, inductors/transformers/magnets, circuits, etc., can solve the problems of one-time molding, low magnetic performance, multiple processing, etc., and achieve dimensional accuracy and surface smoothness High, good magnetic performance, and the effect of preventing cracks and pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

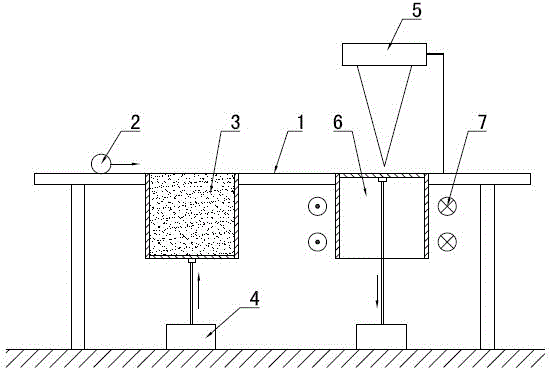

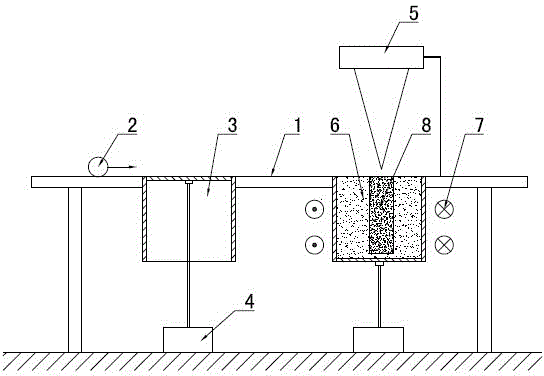

[0025] figure 1 It is the best embodiment of the laser selective sintering molding device of the rare earth permanent magnet device, and the following is combined with the attached Figure 1-2 The present invention will be further described.

[0026] Refer to attached figure 1 Disclosed is a laser selective sintering molding device for a rare earth permanent magnet device, comprising a working table 1, a powder spreading roller 2, a powder cylinder 3, a molding cylinder 6 and a laser 5. A rollable powder spreading roller 2 is provided on the upper part of the work surface 1, and a powder cylinder 3 and a forming cylinder 6 are provided on the lower part of the work surface 1. The powder cylinder 3 is filled with magnetic powder, and the bottom of the powder cylinder 3 and the forming cylinder 6 are equipped with controllable The linear lifting motor 4 of bottom plate lifting, the bottom plate of forming cylinder 6 is flush with worktable 1 in initial state. The upper part o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com