Friction power generating and electromagnetic power generating hybrid power generating system

A technology of hybrid power generation and friction power generation, applied in the direction of friction generators, electrical components, electromechanical devices, etc., can solve problems such as low power generation efficiency, and achieve the effect of improving power generation efficiency, high efficiency, and increasing energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to fully understand the purpose, features and effects of the present invention, the present invention will be described in detail through the following specific embodiments, but the present invention is not limited thereto.

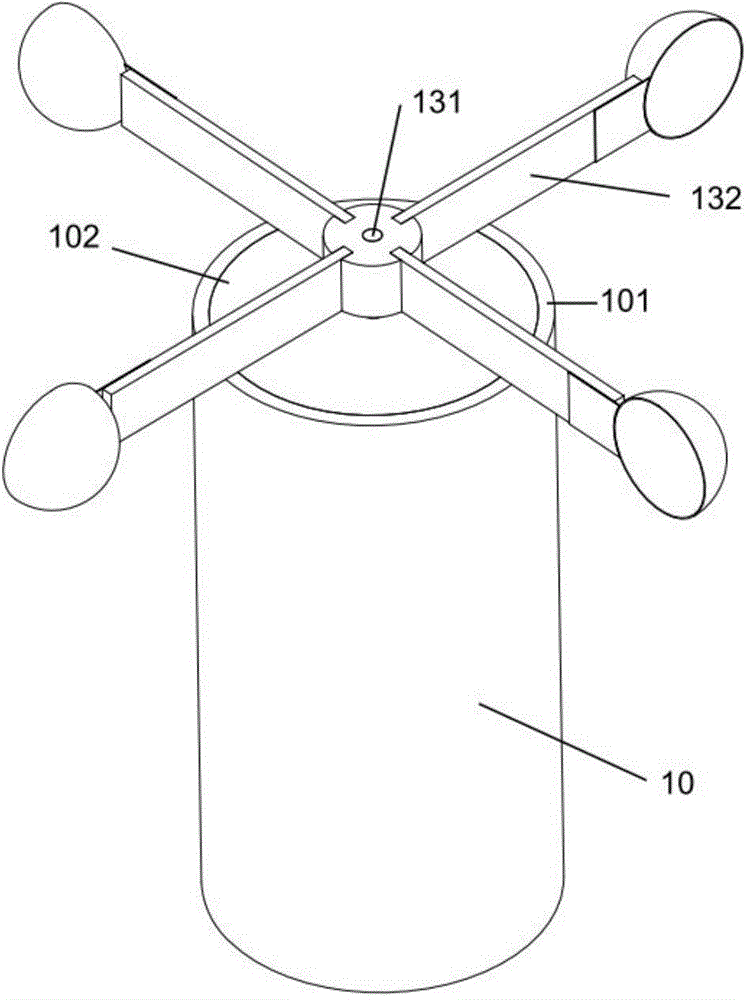

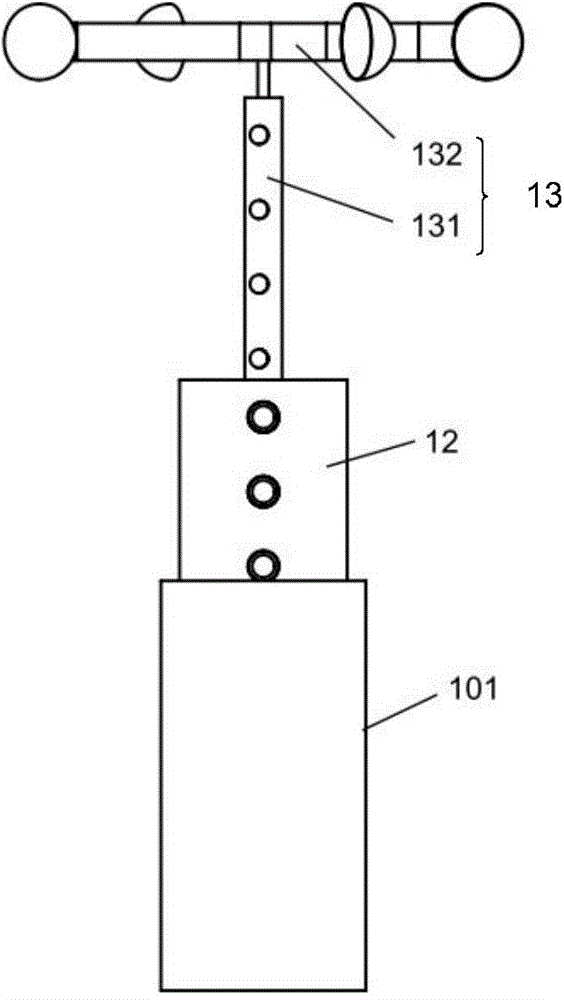

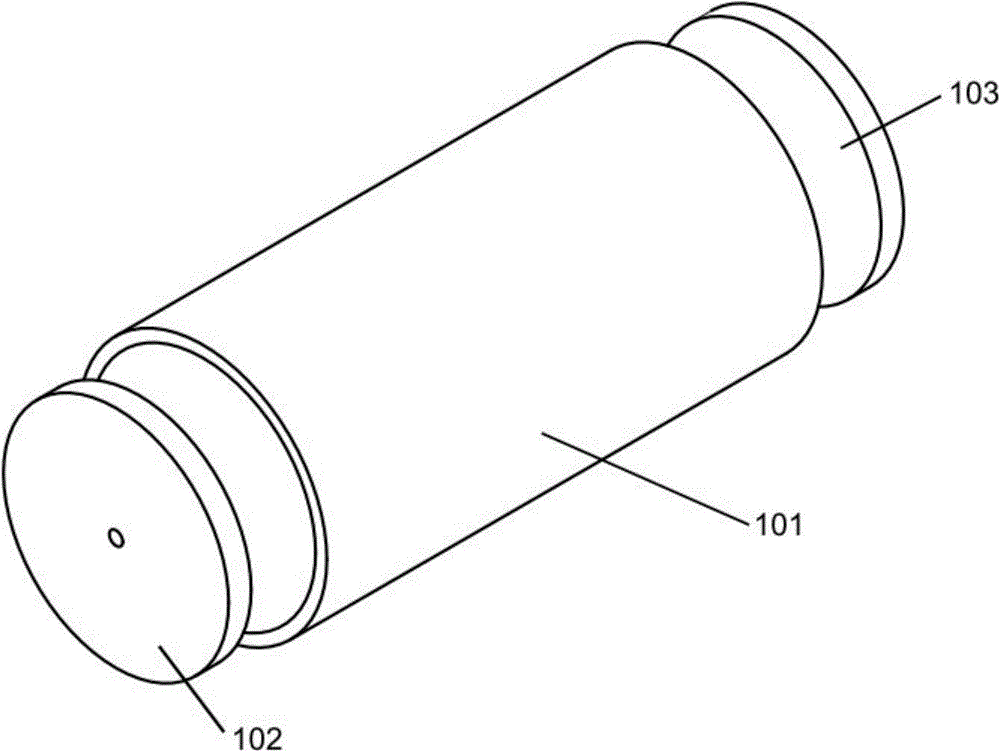

[0029] Figure 1a with 1b A perspective structure diagram and an exploded structure diagram of a hybrid power generation system of friction power generation and electromagnetic power generation provided by an embodiment of the present invention are shown. Figure 1a Shown is a shield support frame 10 comprising a cover body 101, an upper cover plate 102 and a lower cover plate (not shown in the figure), engaged with the upper cover plate 102 of the shield support frame 10 and partially exposed to the outside of the cover body 101 The rotating shaft 131 and the radial fan 132 fixed on one end of the rotating shaft 131 . The main power generation components of the hybrid power generation system are accommodated in the shroud support frame. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com