Method for prolonging shelf life of fermented milk by employing biological conservation strains

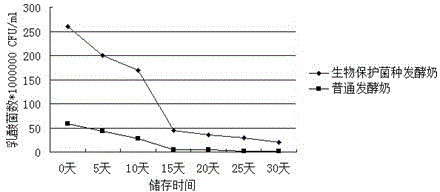

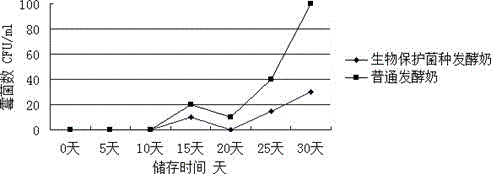

A technology for fermented milk and shelf life, which is applied in applications, milk preparations, dairy products, etc. It can solve the problems of losing the health care function of fermented milk, shortening the shelf life of yogurt, polluting yeast or mold, and achieving mildew and gas production. Effects of reducing, ensuring nutrition and health functions, and extending shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

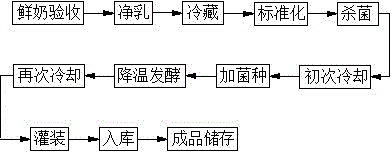

[0030] A method for extending the shelf life of fermented milk with biological protection strains is carried out as follows:

[0031] (1) Fresh milk acceptance: After fresh milk arrives at the factory, the fat protein content is analyzed first, requiring fat ≥ 3.20%, protein ≥ 2.95%, and then 15 routine index tests such as alcohol test, acidity, pH, boiling and tasting without peculiar smell , And test negative for antibiotics, and release after qualified to ensure the quality of fresh milk;

[0032] (2) Clean milk: use a high-speed centrifuge to separate impurities in the milk, the centrifuge speed is 6500 revolutions per minute;

[0033] (3) Refrigeration: the clean milk is quickly cooled to 2~4℃ for refrigeration;

[0034] (4) Standardization: Adjust the fat-protein ratio of milk, heat the milk to 60~65℃, add white sugar, acetylated distarch phosphate and pectin, fully dissolve and mix well, the fat-protein content of fresh milk is fat ≧ 2.94 %, protein ≧2.71%, chilled to 2℃~4℃; a...

Embodiment 2

[0054] A method to extend the shelf life of fermented milk with biological protection bacteria, except for step (4), “adjust the fat-protein ratio of fresh milk by adding cream or skimmed milk with a fat content≦0.54% and a protein content≦3.07%, per ton Except that the milk addition amount is 35-38%", the other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com