Flue gas demisting device and method manufacturing flue gas demisting device

A defogging device and flue gas technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as deformation of defogging elements, design of helical combs, cumbersome processing, manual welding, etc., to strengthen the fixation. , The stable effect of the defogging device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108] Example 1: Demister element holder

[0109] Such as Figure 11 As shown, this embodiment shows a demister element clamping piece 121 of a preferred embodiment of the present invention, which is used for fixing the demisting element. The clamping piece 121 includes a clamping part 1211, and the clamping part 1211 is set as It can be tightly matched with the side edge of the defogging element in a clamping manner. The clamping portion 1211 includes a first clamping flap 12111 and a second clamping flap 12112 .

[0110]The first clamping flap 12111 and the second clamping flap 12112 are respectively provided with first grooves 121111, and the first grooves 121111 are set to be able to match the first flange 011 of the side edge of the defogging element work close with. The first groove on the first clamping flap 12111 and the first groove on the second clamping flap 12112 together form an accommodating space for accommodating the first flange 011 on the side edge of the...

Embodiment 2

[0118] Embodiment 2: Demisting device

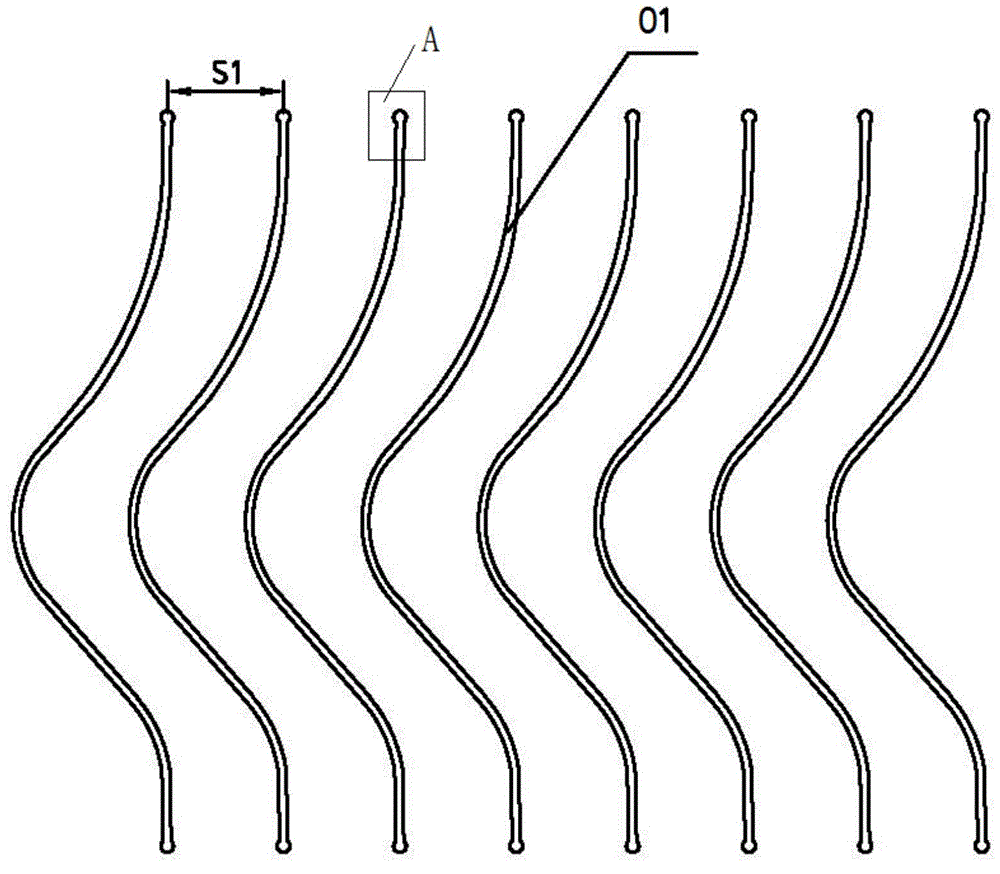

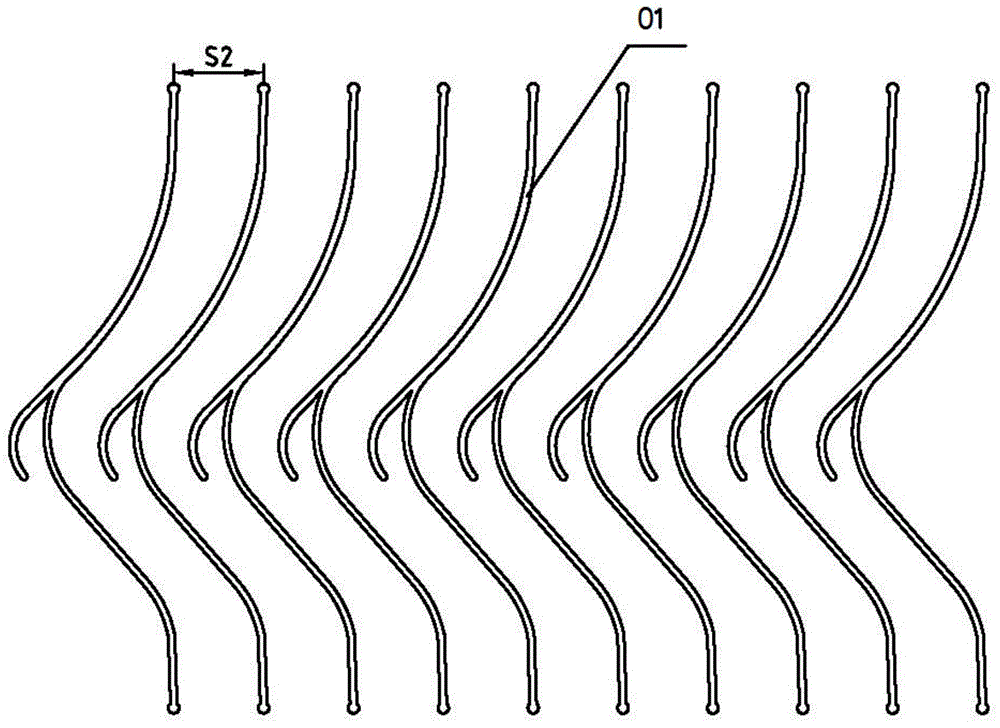

[0119] This embodiment is a preferred flue gas demister device 1 of the present invention, such as Figure 17 As shown, it includes a defogging assembly and a limiting assembly for fixing the defogging assembly. The defogging assembly includes a plurality of defogging elements 01. In this embodiment, the defogging elements 01 are corrugated plates. The limiting assembly includes a plurality of first A limiting element 121 and a plurality of second limiting elements 122. In this embodiment, the first limiting element 121 is the clamping member in Embodiment 1, and the second limiting element 122 is a connecting strip, and the connecting strip is in the shape of a strip Plastic plates. When the limiting assembly is used to fix the defogging assembly, the defogging element 01 is connected to the second limiting element 122 through the first limiting element 121, and one first limiting element 121 is correspondingly connected to one defoggi...

Embodiment 3

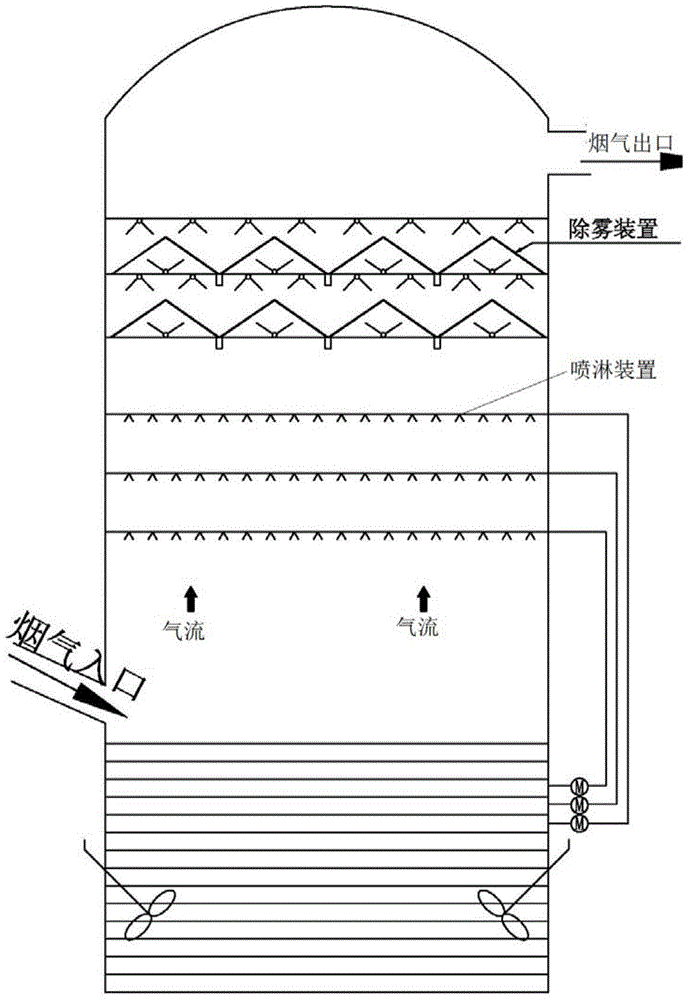

[0129] Embodiment 3 Tubular Roof Mist Eliminator

[0130] This example shows a preferred embodiment according to the present invention, which is a tubular roof mist eliminator (pipe roof mist eliminator), see Figure 23 , 24 , a tubular roof mist eliminator is configured in a circular absorption tower according to the design method of no blind zone coverage. The tubular roof mist eliminator includes a tubular roof mist eliminator 60, a first-stage roof mist eliminator 70, a second-stage roof mist eliminator 80 and a multi-layer flushing system 90, which is used for airflow flowing from bottom to top Separation of mist droplets in the airflow.

[0131] In the tubular roof demister, the tubular demister, the first-stage roof demister 70 and the first-floor flushing system (from bottom to top) are collectively installed on the lower support beam 17; the second-stage roof demister The fogger and the rest of the three-layer flushing system are collectively installed on the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com