A special separation membrane for dye desalting and refining

A separation membrane, desalination technology, used in semi-permeable membrane separation, membrane technology, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

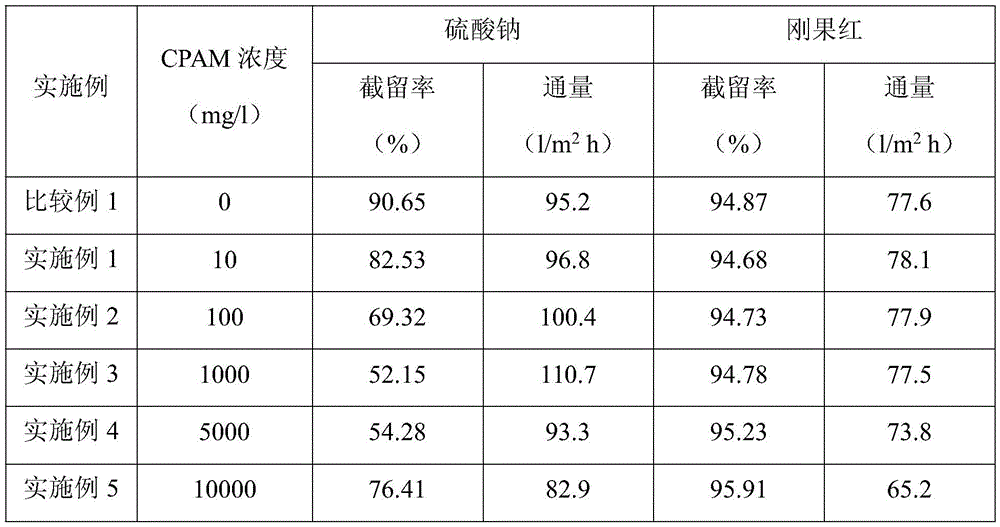

[0023] The difference from Comparative Example 1 is that after the conventional composite nanofiltration membrane is obtained, the aqueous solution containing 10 mg / l cationic polyacrylamide is evenly sprayed on the surface of the above-mentioned membrane, and then dried at 50-70°C for 5 minutes to complete the membrane. Preparation of slices.

[0024] Under the conditions of pressure of 0.5MPa, temperature of 25°C, and pH value of 6.5 to 7.5, 500mg / l sodium sulfate aqueous solution and 100mg / l Congo red aqueous solution were respectively used as feed liquids to test the composite nanofiltration membrane for sulfuric acid Sodium and Congo red dye molecule retention rate and the corresponding water flux, the results are shown in Table 1.

Embodiment 2

[0026] The difference from Comparative Example 1 is that after the conventional composite nanofiltration membrane is obtained, the aqueous solution containing 100 mg / l cationic polyacrylamide is uniformly sprayed on the surface of the above-mentioned membrane, and then dried at 50-70°C for 5 minutes to complete the membrane Preparation of slices.

[0027] Under the conditions of pressure of 0.5MPa, temperature of 25°C, and pH value of 6.5 to 7.5, 500mg / l sodium sulfate aqueous solution and 100mg / l Congo red aqueous solution were respectively used as feed liquids to test the composite nanofiltration membrane for sulfuric acid Sodium and Congo red dye molecule retention rate and the corresponding water flux, the results are shown in Table 1.

Embodiment 3

[0029] The difference from Comparative Example 1 is that after the conventional composite nanofiltration membrane is obtained, the aqueous solution containing 1000 mg / l cationic polyacrylamide is uniformly sprayed on the surface of the above-mentioned membrane, and then dried at 50-70°C for 5 minutes to complete the membrane Preparation of slices.

[0030] Under the conditions of pressure of 0.5MPa, temperature of 25°C, and pH value of 6.5 to 7.5, 500mg / l sodium sulfate aqueous solution and 100mg / l Congo red aqueous solution were respectively used as feed liquids to test the composite nanofiltration membrane for sulfuric acid Sodium and Congo red dye molecule retention rate and the corresponding water flux, the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com