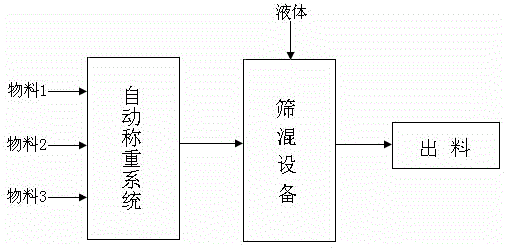

A material screening and mixing process

A material screening and process technology, which is applied in the mixing of granular or powdery solid materials in the chemical industry and in the field of medicine, can solve the problems of poor efficiency, poor mixing effect, long mixing time, etc., achieve small power, save energy, and reduce ingredients. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

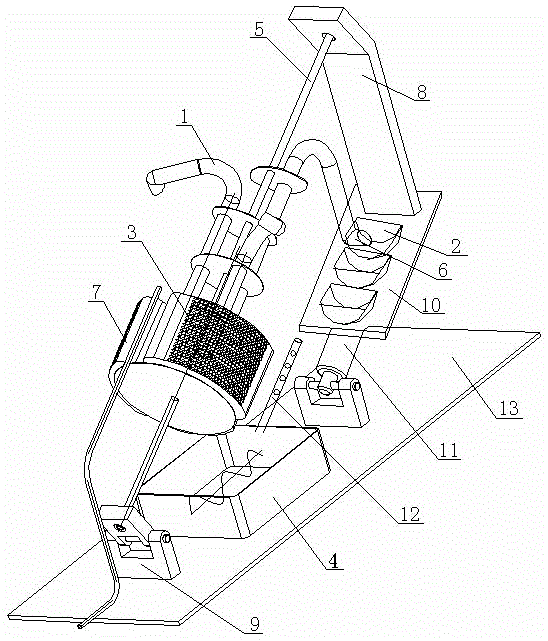

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] see figure 2 , a material screening and mixing process, wherein the material screening and mixing equipment includes two or more feed pipes 1, two or more raw material bins 2, two or more sieve buckets 3 , receiving tray 4, rotating shaft 5, liquid spray mist equipment 12 and base 13. The feed pipe 1, the raw material bin 2 and the sieve bucket 3 correspond one by one, and the feed opening of the feed pipe 1 is bent to form a digging shovel 6, and the digging shovel 6 is matched with the corresponding raw material bin 2 ; The outlet of the feed pipe 1 is connected to the mouth of the corresponding sieve bucket 3, and the two or more sieve buckets 3 are respectively fixed on the rotating shaft 5, and the two or more sieve buckets The buckets 3 are connected by edges to form a bucket 7, and the outer end bucket wall of the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com