Atomizing device for space spray coating

A technology of atomization device and space, applied in the direction of spray device, spray device, etc., can solve the problems of hollow, split beam, uneven atomization surface, etc., achieve strong flexibility, expand the scope of use, and excellent uniform atomization effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

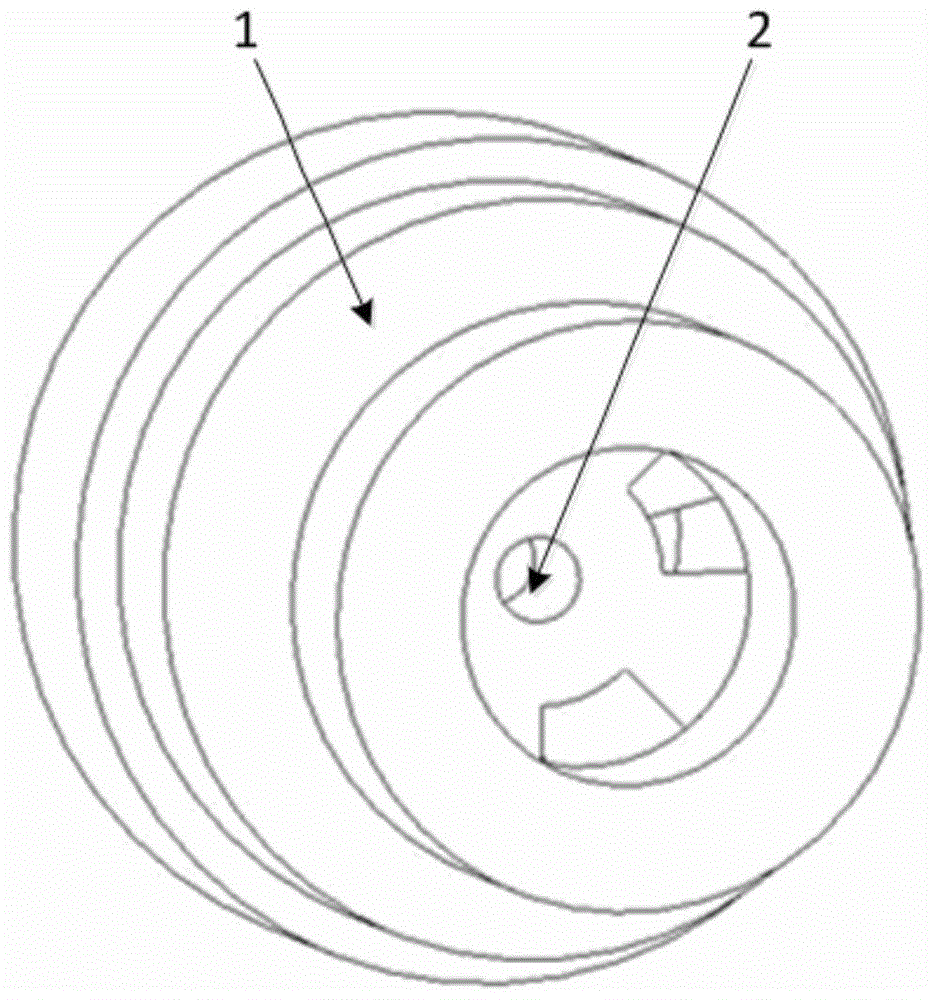

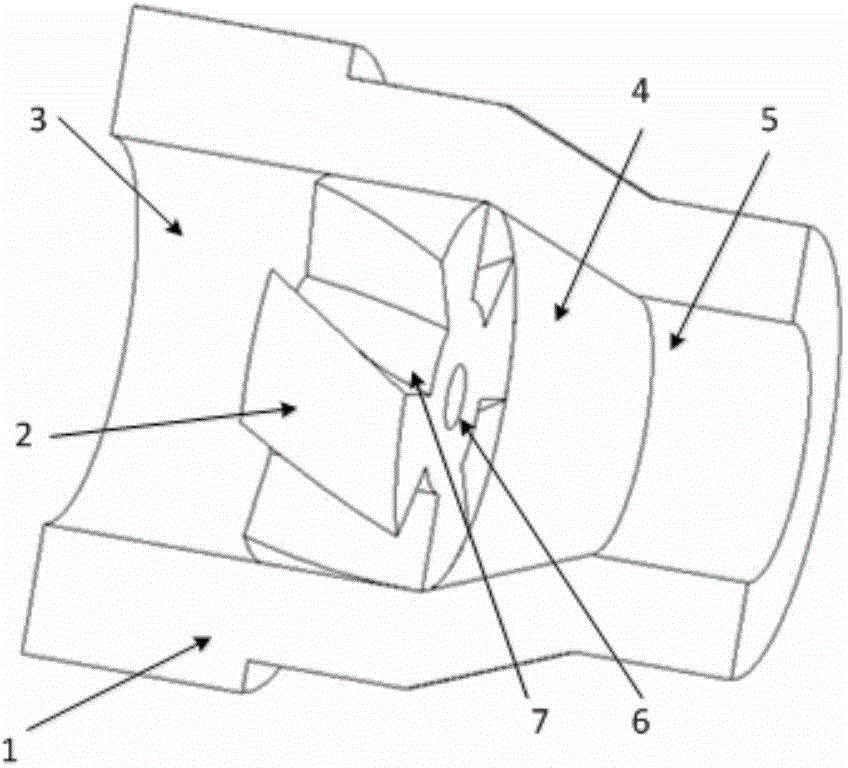

[0021] Such as figure 1 , figure 2 Shown is the structural composition diagram of the nozzle device of the present invention, one end of the nozzle device is the liquid inlet side, and the other end is the liquid outlet side, including: swirl chamber 1 and swirl core 2, swirl chamber 1 mainly consists of three parts Composition: Inlet section 3, Convergence section 4, Exit section 5. The swirl core 2 mainly includes a central hole flow channel 6 and four spiral guide flow channels 7 equidistant from the periphery. The swirl core 2 is installed on the innermost side of the inlet section of the swirl chamber 1 (near the converging section 4), and the swirl chamber 1 and the swirl core 2 are fixed by interference fit.

[0022] The inlet section 3 and the outlet section 5 of the swirl chamber 1 are cylindrical, and the converging section 4 is conical, with circular cross-sections. The main function of the swirl chamber 1 is to convert the pressure energy of the liquid to be at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com