Automobile cylinder cover machining method

A processing method and cylinder head technology, applied to cylinder heads, cylinders, engine components, etc., can solve problems such as high production costs, endangering use safety, complex processing, etc., achieve convenient processing, reduce production costs, improve product quality and use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

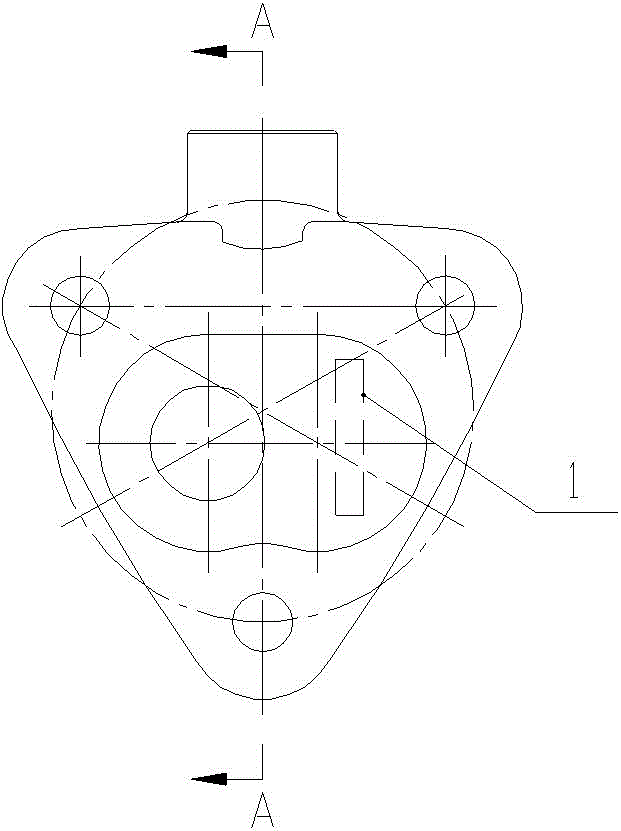

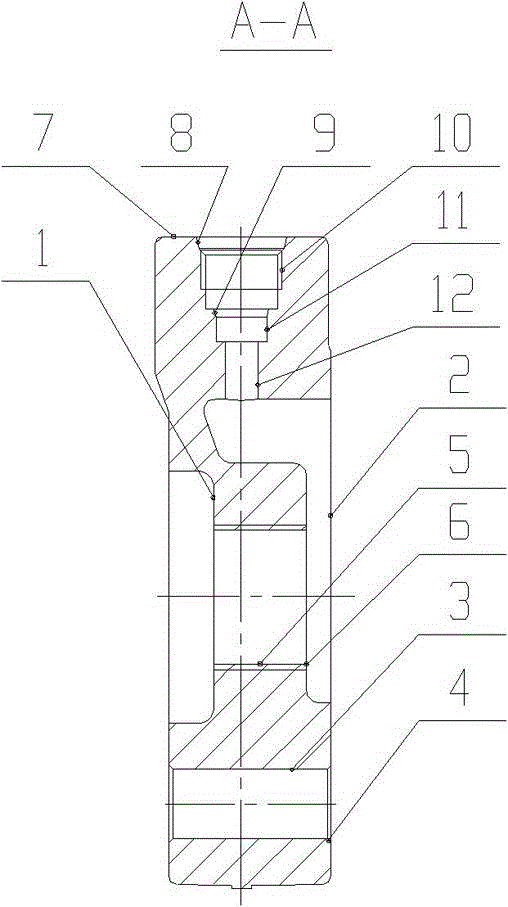

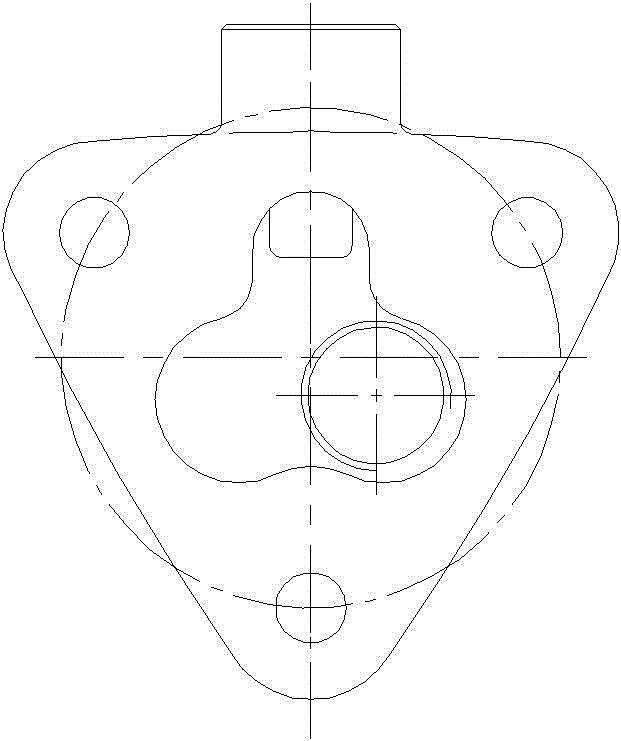

[0031] The present invention will be further described below in conjunction with the accompanying drawings: a processing method for an automobile cylinder head, including the following processing steps: 1), aluminum blank casting; 2), use a MARK-Ⅲ laser marking machine to engrave Product batch number, visual inspection; 3), put the cylinder head into a special circulation box; 4), use a three-jaw chuck to clamp the triangle fillet of the cylinder head on the CK50 CNC lathe, and select the spindle speed as 280m / min , MCLNR2525M12 tool holder and 160404 gemstone blade, feed speed 0.08mm / r, turning plane B2, process to the design drawing requirements, use vernier calipers, three-coordinate measuring instrument, roughness sample, visual inspection, and the thickness inspection is random inspection every 10 pieces 1 piece, the depth inspection is 1 piece for every 10 pieces, and the surface roughness inspection is 1 piece for every 10 pieces; 5) Use a 4mm flat file to remove sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com