Railroad box car inside ceiling panel

A railway boxcar and roof technology, which is applied to the railway roof and other directions, can solve the problems of poor thermal insulation performance of the roof of pure metal structure, difficulty in meeting the use requirements of railway boxcars, poor moisture resistance of bamboo laminates, etc., and achieve excellent weather resistance and mechanical properties performance, improved structural properties, improved thermal insulation properties and flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

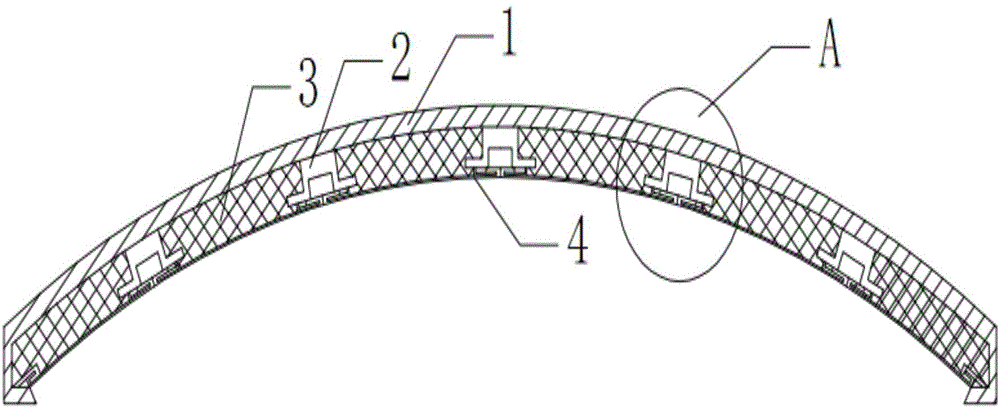

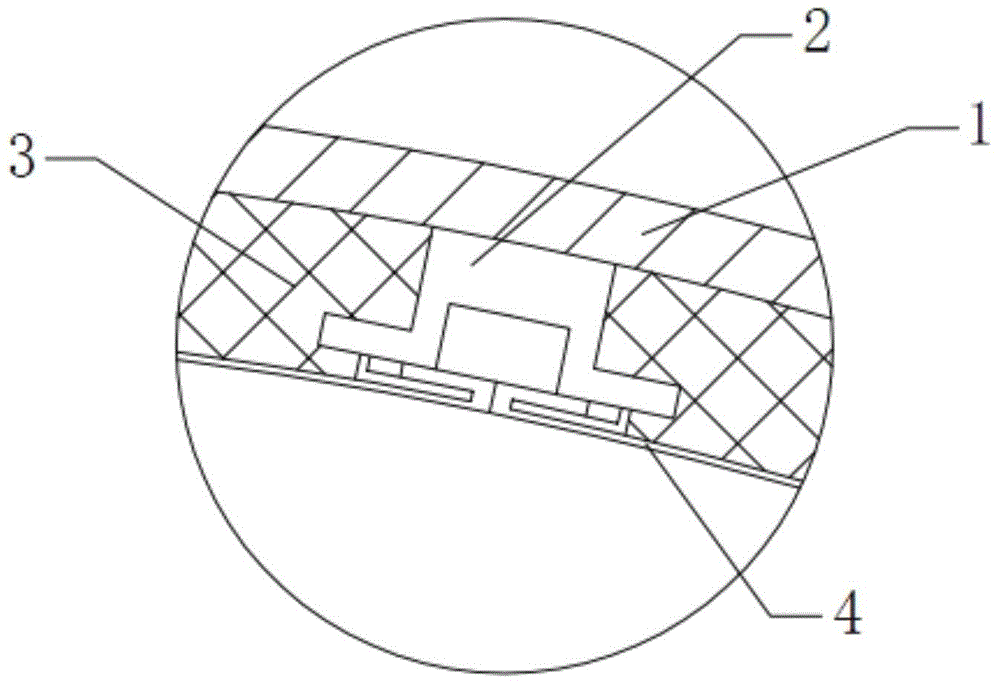

[0017] Embodiment 1: In this embodiment, the thermal insulation material 3 filled between the hat-shaped steels 2 is rigid polyurethane foam, and the arc-shaped structural plate 4 is a glass fiber reinforced polyurethane composite plate, and the glass fiber reinforced polyurethane composite plate is The screw is fixedly connected with the cap steel 2.

[0018] The specific method is to first bond polyurethane rigid foam to the arc-shaped top plate between adjacent hat-shaped steels with the help of adhesives, and then use screws to fix the glass fiber reinforced polyurethane composite sheet of the overall structure on the hat-shaped steel. The screw head rubs against the goods during transportation. The screw in the present invention uses a countersunk screw, and the countersunk through-hole is pre-set on the glass fiber reinforced polyurethane composite plate. On the other hand, in order to ensure ventilation, the arc-shaped structure in the present invention A cylindrical ve...

Embodiment 2

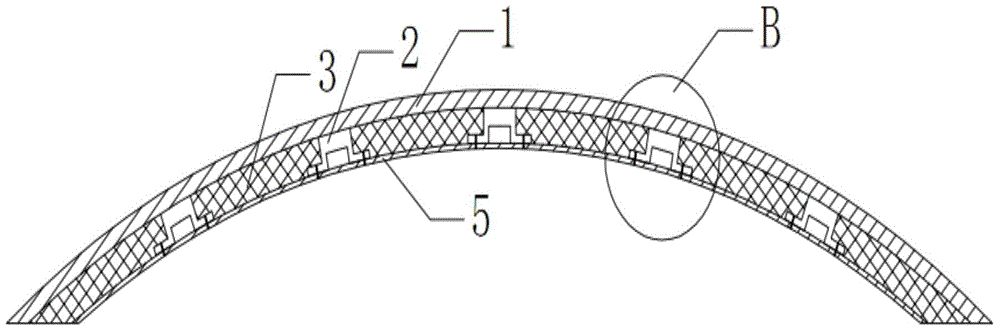

[0019] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the arc structural plate adopted is an assembled structure, and the arc structural plate is made of glass fiber reinforced polyurethane plate, and the two ends of the arc structural plate 4 are provided with Inwardly bent hooks, the bottom of the hat-shaped steel 2 is provided with two slots opposite to each other, and the hooks at both ends of the arc-shaped structural plate 4 are respectively engaged with the slots at the bottom of two adjacent sets of hat-shaped steel 2 , the arc-shaped structural plate 4 includes at least two unit plates.

[0020] The specific method is to first bond the insulation material between the hat-shaped steels, the insulation material is still polyurethane rigid foam, and at the same time weld the card slot on the hat-shaped steel (see attached Figure 3-4 ), and then insert the curved structural plates with hooks into the slots in sequence to complete the splici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com