Power bogie adopting traditional wheel sets for 100% low-floor light rail vehicle

A power bogie and low-floor technology, applied in the direction of the device for lateral relative movement between the underframe and the bogie, axle box installation, etc., to achieve the effects of improving comfort, facilitating modular design, and improving anti-roll performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

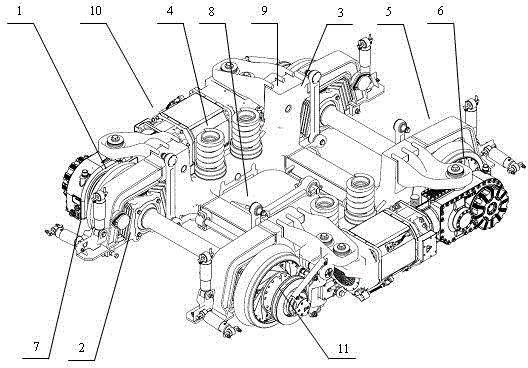

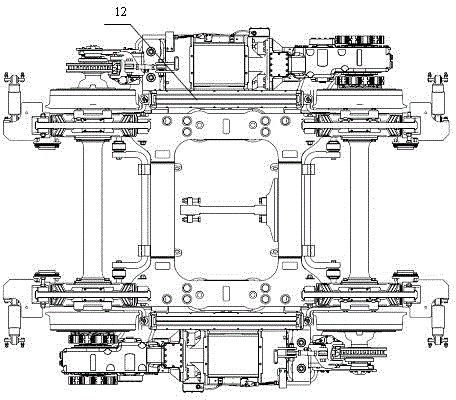

[0008] refer to figure 1 , figure 2 , the bogie of the present invention is made up of following parts: frame 1, wheelset composition 2, first series spring 3, second series spring 4, second series vertical shock absorber 5, second series transverse shock absorber 6, second series transverse buffer device 7, single traction rod 8, anti-roll torsion bar 9, elastic frame suspension longitudinal drive device 10, hydraulic brake unit 11 and magnetic rail brake 12. The wheel set adopts the wheel-axle structure, the axle box is built in, and the wheels are elastic wheels with a diameter of Φ500mm-Φ580mm. Two sets of anti-roll torsion bars are installed on the outside of the beam.

[0009] The height of the wheel to axle is the key component to lower the floor of the car body. The use of elastic wheels with a diameter of Φ500mm-Φ580mm reduces the height of the axle and provides space for lowering the floor of the car body. At the same time, the elastic wheels have the function of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com