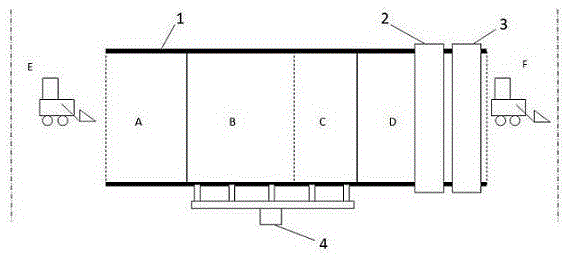

Continuous biological drying method and equipment for organic solid waste with high moisture content

A technology of biological drying and organic solid waste, which is applied in chemical instruments and methods, water pollutants, biological sludge treatment, etc., can solve the problems of increased energy consumption, low particle bulkiness, and large footprint, and achieves Accelerate oxygen supplementation, reduce production cost and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

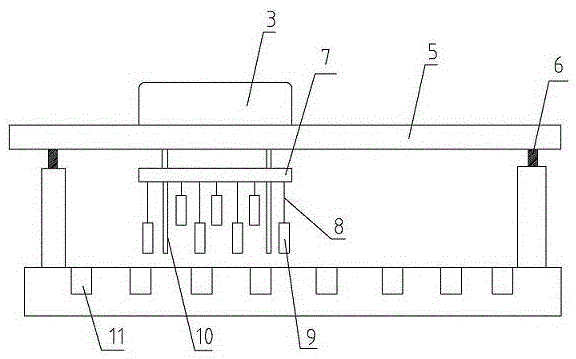

Method used

Image

Examples

Embodiment 1

[0033] (1) Municipal domestic sludge with a water content of 80-85% sent from the urban sewage plant, alcohol residue with a water content of 75-85% sent from the alcohol factory, and water content of 55%-55% sent from the starch factory 70% fly ash is mixed with a forklift in the organic solid waste batching area according to the volume ratio of 1:1:0.15, and then moved to the material pre-mixing area for stacking, and then the mixed material is removed from the material pre-mixing area by a cloth reclaimer Transfer to the natural gravity drainage and drying area, start the turning machine to mix the materials evenly, and then let it stand for 2 to 5 days for pre-fermentation, so that the water will flow into the natural gravity drainage from high to bottom under the action of gravity The bottom ventilation channel of the drying area is collected and flowed out, and intermittent medium and high pressure air supply is adopted at the bottom of the natural gravity drainage drying...

Embodiment 2

[0037] (1) The sugar filter sludge with a moisture content of 75-85% and the bagasse with a moisture content of 75-85% sent from the sugar factory are mixed in the organic solid waste batching area with a forklift according to the volume ratio of 1:1.5 After batching, move to the material pre-mixing area for stacking, and then use the material reclaimer to transfer the mixed materials from the material pre-mixing area to the natural gravity drainage and drying area, start the turner to turn the material evenly and then let it stand for 2~ 5 days, carry out pre-fermentation, let the water flow into the bottom ventilation channel of the natural gravity drainage and drying area from high to downward by natural gravity under the action of universal gravitation, and flow out intermittently at the bottom of the natural gravity drainage and drying area Medium and high pressure air supply;

[0038] (2) When the moisture in the upper layer of the mixed material in the natural gravity d...

Embodiment 3

[0041] (1) Paper pulping sludge with a moisture content of 75-85% from the paper mill and cassava residue with a moisture content of 75-85% from the alcohol plant are placed in organic solids with a forklift at a volume ratio of 1:1. After mixing the ingredients in the waste batching area, move them to the material pre-mixing area for stacking, and then use the cloth reclaimer to transfer the mixed materials from the material pre-mixing area to the natural gravity drainage and drying area, and start the turning machine to turn and mix the materials evenly After standing still for 2 to 5 days, pre-fermentation is carried out, so that the water, under the action of universal gravitation, flows into the bottom ventilation channel of the natural gravity drainage and drying area by natural gravity from high to downward to collect and flow out, and then flows out in the natural gravity drainage and drying area. The bottom adopts intermittent medium and high pressure air supply;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com