Method for preparing oxaliplatin

A technology of oxaliplatin and potassium tetrachloroplatinite, which is applied in the field of preparation of oxaliplatin, can solve the problems of complex oxaliplatin production process, affecting the treatment effect of patients, and high impurity content, so as to reduce drug prices , reducing medical costs, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

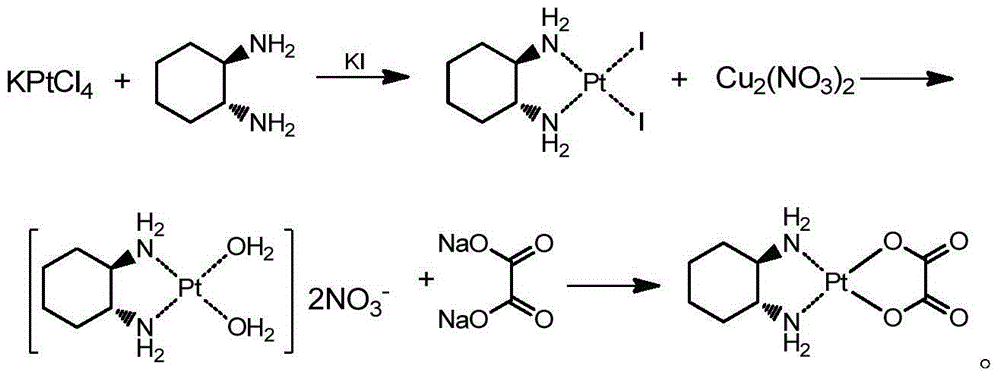

[0020] The preparation method of oxaliplatin of the present invention comprises the following steps:

[0021] Step 1, Potassium tetrachloroplatinite reacts with potassium iodide, (1R, 2R)-cyclohexanediamine to prepare iodoplatinum; potassium tetrachloroplatinite: potassium iodide: (1R, 2R)-cyclohexanediamine=1 : 4.0-6.0: 1.0-1.15 (molar ratio), preferably potassium tetrachloroplatinite: potassium iodide: (1R, 2R)-cyclohexanediamine=1:4.5:1.06. The reaction temperature in step 1 is controlled at 20-30°C, preferably 25°C. In step 1, the reaction liquid is filtered, and the filter cake is washed with purified water, and the last filtrate is pH=6-8 (preferably pH=7).

[0022] Step 2, the nitrate intermediate of ammonia platinum in step 1 and cuprous nitrate reaction obtains aminoplatinum; Iodine ammonia platinum: cuprous nitrate=1: 1~1.05 (molar ratio), preferably iodine ammonia platinum: cuprous nitrate =1:1.02. The reaction temperature in step 2 is controlled at 20-30°C, pref...

Embodiment 1

[0027] Add 35 g of potassium tetrachloroplatinite and 70 mL of purified water into the reaction flask, and stir to dissolve. Weigh 63g of potassium iodide, add 75mL of water to dissolve. Slowly add potassium iodide aqueous solution to potassium tetrachloroplatinite filtrate, and stir at room temperature for 30 min in the dark. Weigh 10.25 g of (1R,2R)-cyclohexanediamine and dissolve it in 70 mL of purified water, and add the solution to the solution of potassium tetrachloroplatinite. Replace the reaction bottle with nitrogen for 5 minutes, stir at room temperature, a brownish-yellow solid is precipitated, and the reaction is not less than 20 hours, and the reaction temperature is 20°C. The reaction solution was filtered, and the filter cake was washed with purified water (3×30 mL). The last filtrate was pH=6-8, and pumped until no liquid dripped out. Wash the solid with 10 mL of absolute ethanol, and pump until there is no liquid drop. Wash the filter cake with 10 mL of anh...

Embodiment 2

[0031] Add 3.5 g of potassium tetrachloroplatinite and 10 mL of purified water into the reaction flask, and stir to dissolve. Weigh 6.3g of potassium iodide, add 10mL of water to dissolve. Slowly add potassium iodide aqueous solution to potassium tetrachloroplatinite filtrate, and stir at room temperature for 30 min in the dark. Weigh 1.1 g of (1R,2R)-cyclohexanediamine and dissolve it in 10 mL of purified water, and add the solution into the solution of potassium tetrachloroplatinite. Replace the reaction bottle with nitrogen for 5 minutes, stir at room temperature, and a brownish-yellow solid precipitates out. The reaction is not less than 15 hours, and the reaction temperature is 25°C. The reaction solution was filtered, and the filter cake was washed with purified water (3×5 mL), and the last filtrate had a pH of 6-8, and was pumped until no liquid dripped out. Wash the solid with 5 mL of absolute ethanol, and pump until there is no liquid drop. Wash the filter cake wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com