A method of manufacturing biological source hybrid advanced composite material and its product

An advanced composite material and bio-sourced technology, which is applied in the field of manufacturing bio-sourced hybrid advanced composite materials, can solve problems such as high fatigue resistance, non-maintaining properties, and inability to impart, and achieve high tensile strength and bond strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

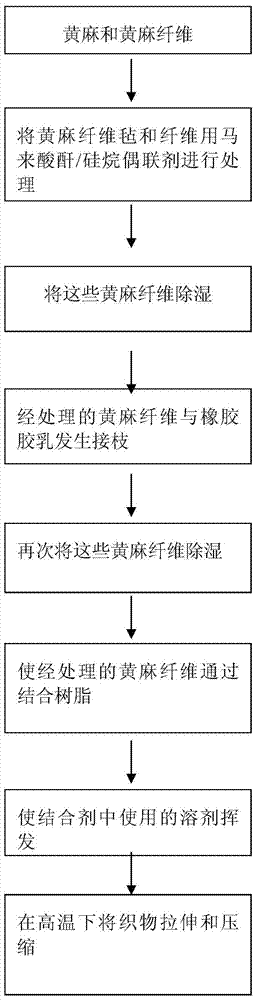

Method used

Image

Examples

Embodiment 1

[0065] The jute mat and jute fibers were passed through a Doctor Box containing 0.5% maleic anhydride. The jute fiber mat and jute fibers were surface treated with maleic anhydride at 80°C and maintained at this temperature until the fiber mat entered another Doctor Box. The treated jute was then passed through another DoctorBox containing SBR latex with 5% solids content. The SBR latex was grafted onto the treated jute fibers at 150°C and this temperature was maintained until the jute fiber mat was dehumidified. Then, the rubberized jute fabric was passed through phenolic in another Doctor Box. The treated jute is pulled out at a speed of 0.5 m / min, and the fiber is wound in a drum.

[0066] Rectangular shapes of raw material (phenolic impregnated jute) were kept layer by layer in proper sequence. The sequentially arranged prepregs are placed in a compression molding machine. at 150kg / cm 2 Under the pressure and temperature of 160 °C, the desired crosslinking and shape a...

Embodiment 2

[0068] The jute mat and jute fibers were passed through a Doctor Box containing 0.5% maleic anhydride. The jute fiber mat and jute fibers were surface treated with maleic anhydride at 50°C and maintained at this temperature until the fiber mat entered another Doctor Box. The treated jute was then passed through another DoctorBox containing SBR latex with 5% solids content. The SBR latex was grafted onto the treated jute fibers at 90°C and this temperature was maintained until the jute fiber mat was dehumidified. Then, the rubberized jute fabric is passed through phenolic resin. The treated jute is pulled out at a speed of 0.2 m / min. The fibers are wound in the form of drums.

[0069] The component is shaped under tension using specially designed dies. The fabric is stretched in windings of roving and sandwiched in other natural fiber mats under an engineered frame, attached to a compression molding die. Keep the rectangular-shaped raw materials in a layer-by-layer structu...

Embodiment 3

[0071] The jute mat and jute fibers were passed through a Doctor Box containing 1.0% maleic anhydride. The jute fiber mat and jute fibers were surface treated with maleic anhydride at 80°C and maintained at this temperature until the fiber mat entered another Doctor Box. The treated jute was then passed through another DoctorBox containing SBR latex with 20% solids content. The SBR latex was grafted onto the treated jute fibers at 150°C and this temperature was maintained until the jute fiber mat was dehumidified. Then, the rubberized jute fabric is passed through a phenolic resin. The treated jute is pulled out at 0.5 m / min and the fibers are wound in drums.

[0072] The rest of the steps were repeated as described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com