Thermo-mechanical treatment strengthening technology of magnesium alloy sheet

A deformation heat treatment, magnesium alloy technology, applied in the field of non-ferrous metals, can solve problems such as limited work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

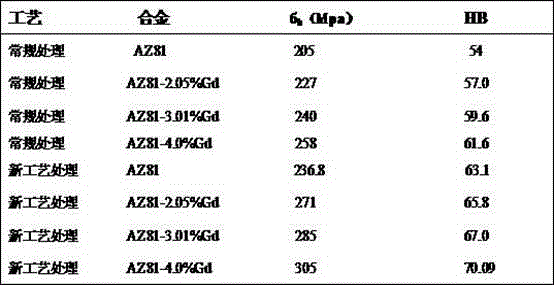

[0043] The magnesium alloy in this embodiment is composed of the following components by mass percentage: 7.8% Al, 0.7% Zn, impurity element Mn<0.12%, 0% Gd, and the rest is Mg.

[0044] Select a representative part from the smelted magnesium alloy ingot to cut a magnesium alloy sheet with a size of 40×40×4mm, and grind the upper and lower surfaces with sandpaper from coarse to fine to make it smooth for use.

[0045] The treated magnesium alloy sheet is subjected to solid solution treatment in a box-type resistance furnace: the heating temperature is 415° C., and the temperature is kept for 20 hours.

[0046] The sample after solution treatment was rolled at 150°C with a deformation of 15%, followed by aging treatment. The process parameters: heating temperature was 168°C, holding time was 8h, and air cooled to room temperature.

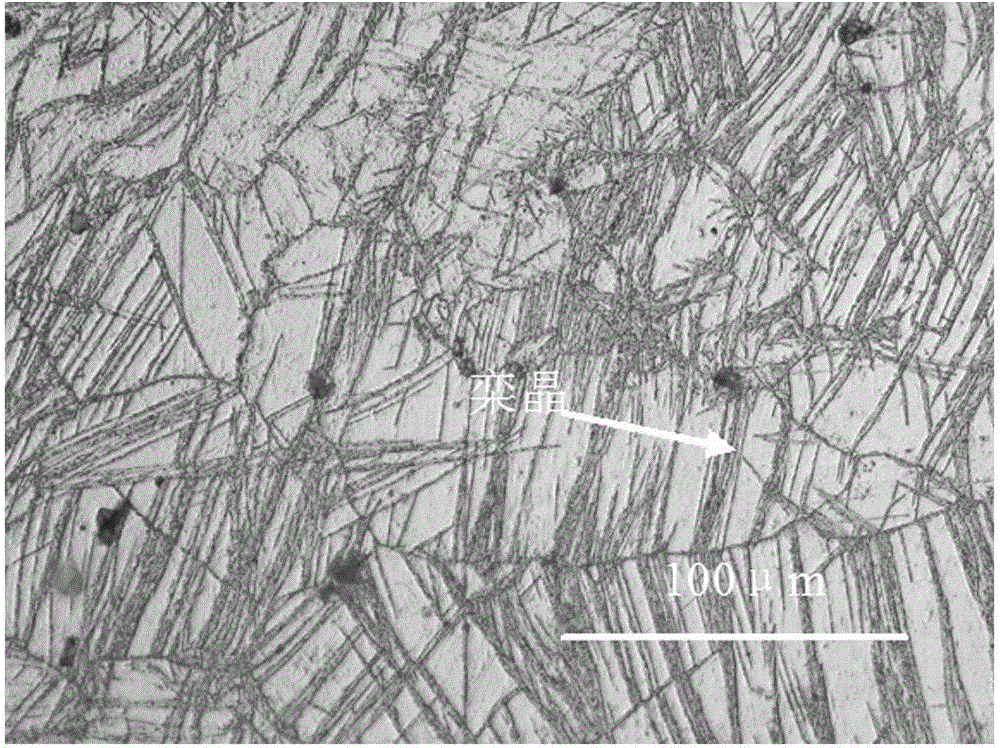

[0047] The microstructure of the high-strength and toughness magnesium alloy obtained in this embodiment is as follows: figure 1 shown, from fi...

Embodiment 2

[0049] The magnesium alloy in this embodiment is composed of the following components by mass percentage: 7.4% Al, 0.78% Zn, impurity element Mn<0.12%, 3.01% Gd, and the rest is Mg.

[0050] Select a representative part from the smelted magnesium alloy ingot to cut a magnesium alloy sheet with a size of 40×40×4mm, and grind the upper and lower surfaces with sandpaper from coarse to fine to make it smooth for use.

[0051] The treated magnesium alloy sheet is subjected to solid solution treatment in a box-type resistance furnace: the heating temperature is 415° C., and the temperature is kept for 20 hours.

[0052] The sample after solution treatment was rolled at 160°C with a deformation of 15%, followed by aging treatment, process parameters: heating temperature was 168°C, holding time was 16h, air cooled to room temperature.

[0053] The high-strength and toughness magnesium alloy obtained in this embodiment has a tensile strength of 285 MPa and a hardness of 67HB.

Embodiment 3

[0055] The magnesium alloy in this embodiment is composed of the following components by mass percentage: 7.0% Al, 0.7% Zn, impurity element Mn<0.12%, 4.0% Gd, and the rest is Mg.

[0056] Select a representative part from the smelted magnesium alloy ingot to cut a magnesium alloy sheet with a size of 40×40×4mm, and grind the upper and lower surfaces with sandpaper from coarse to fine to make it smooth for use.

[0057] The treated magnesium alloy sheet is subjected to solid solution treatment in a box-type resistance furnace: the heating temperature is 415° C., and the temperature is kept for 20 hours.

[0058] The sample after solution treatment was rolled at 150°C with a deformation of 15%, followed by aging treatment, process parameters: heating temperature was 168°C and holding time was 12h, air cooled to room temperature.

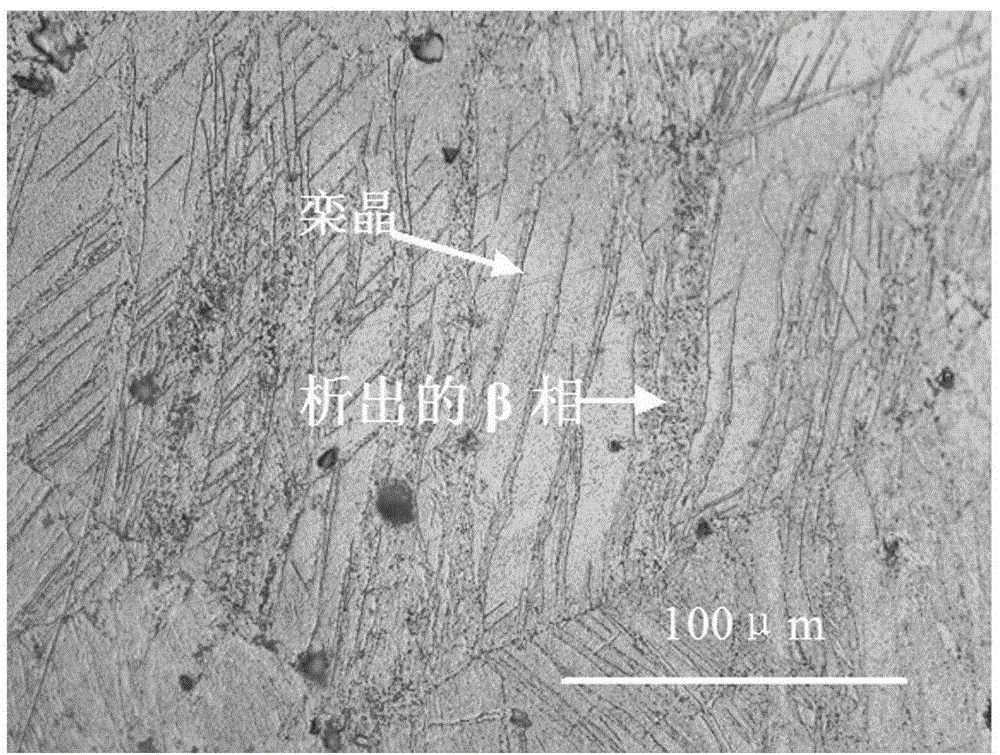

[0059] The microstructure of the high-strength and toughness magnesium alloy obtained in this embodiment is as follows: figure 2 shown, from figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com