Electrolytic manganese negative plate mechanized inlet-outlet cell system and working method

A cathode plate, access and exit technology, applied in the field of electrolytic manganese industry, can solve the problems of complex loading and unloading process, non-continuous transfer, etc., and achieve the effect of facilitating maintenance, facilitating maintenance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

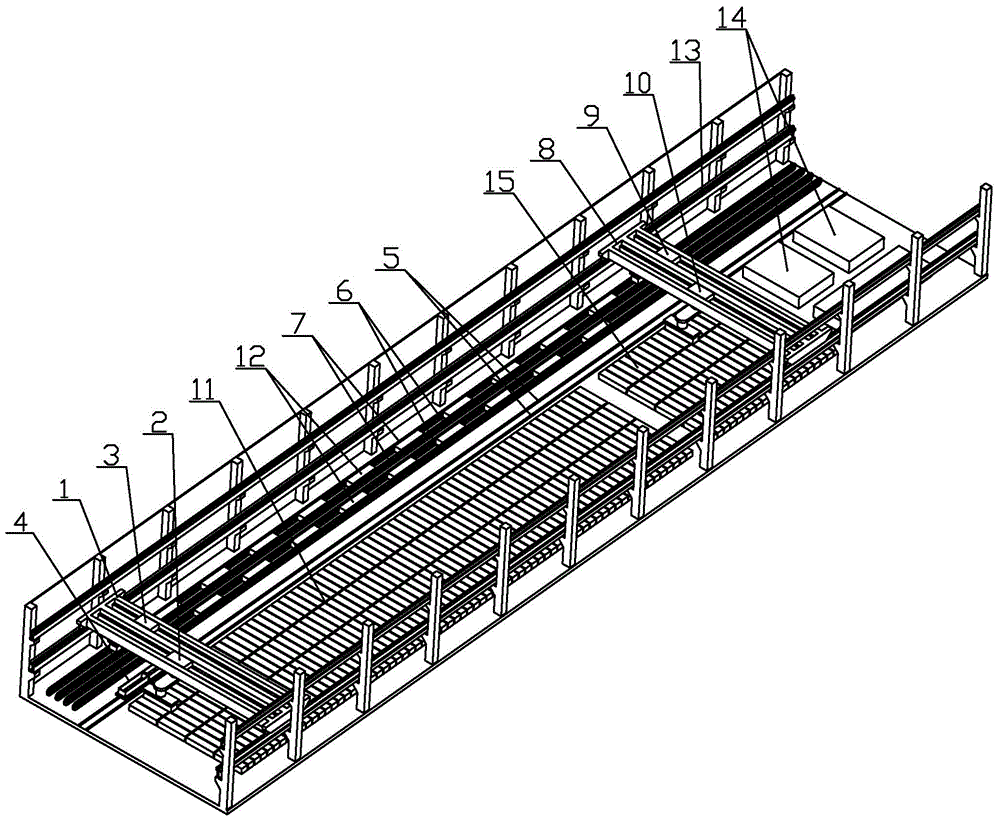

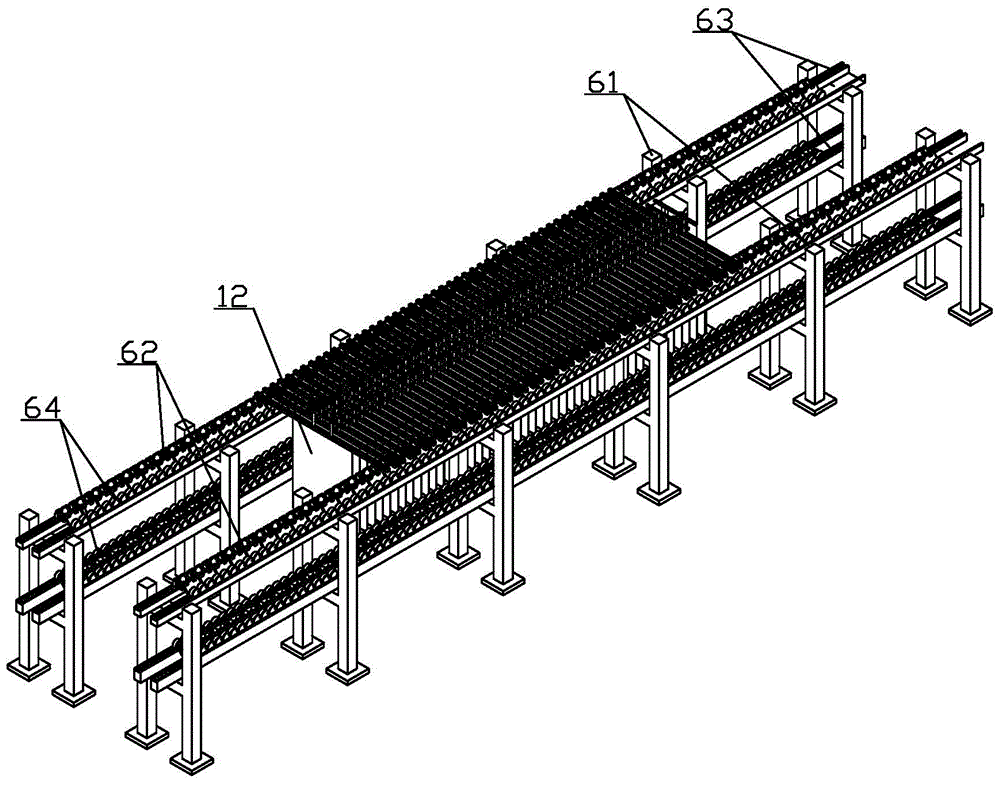

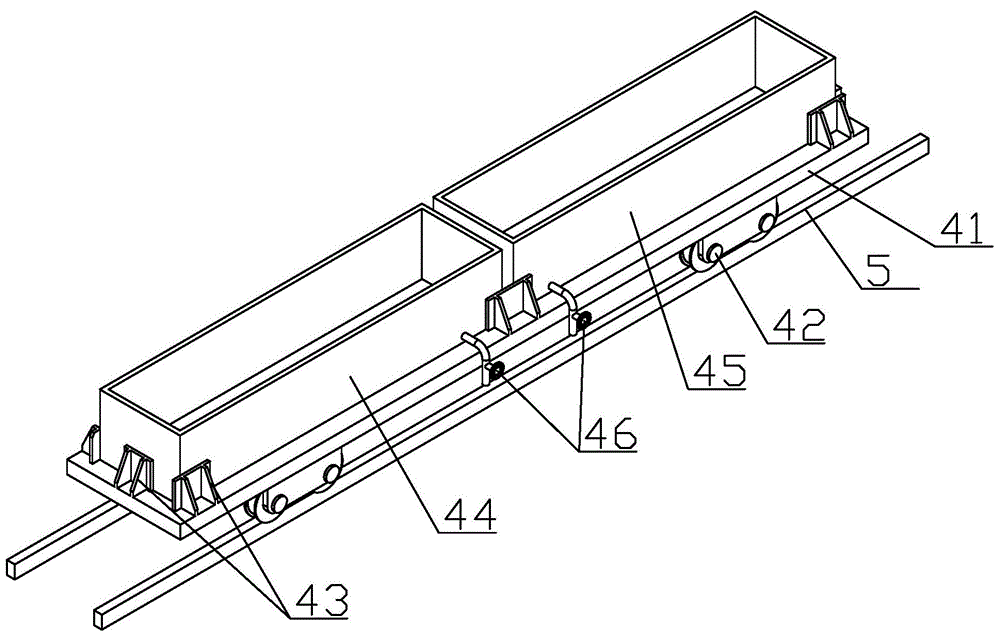

[0039] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-3 As shown, a mechanized entry and exit system for electrolytic manganese cathode plates, including No. 1 crane 1, exit manipulator 2, entry manipulator 3, heavy metal cutting mobile platform 4, guide rail 5, cathode plate output device 6, and cathode plate input device 7. No. 2 crane 8, No. 1 transfer manipulator 9, No. 2 transfer manipulator 10, electrolytic tank 11, whole tank cathode plate 12, track beam 13, stripping equipment 14 and storage rack 15.

[0040] The track beams 13 are installed on the columns of the workshop on both sides of the electrolytic cell 11, and the No. 1 crane 1 is installed on the track beams 13 on both sides above the electrolytic cell 11, and can move longitudinally along the track beams 13; The slot-out manipulator 2 and the slot-entry manipulator 3 are respectively installed in parallel on the main beam of No. 1 crane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com