Needle-bed crankshaft and connecting rod mechanism of single-needle-bed warp knitting machine

A technology of crankshaft connecting rod and connecting rod mechanism, used in warp knitting, knitting, textiles and papermaking, etc., can solve problems such as limiting machine production efficiency, large inertia and centrifugal force, affecting machine running speed, etc., and achieves low vibration and inertia. Small, low-wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

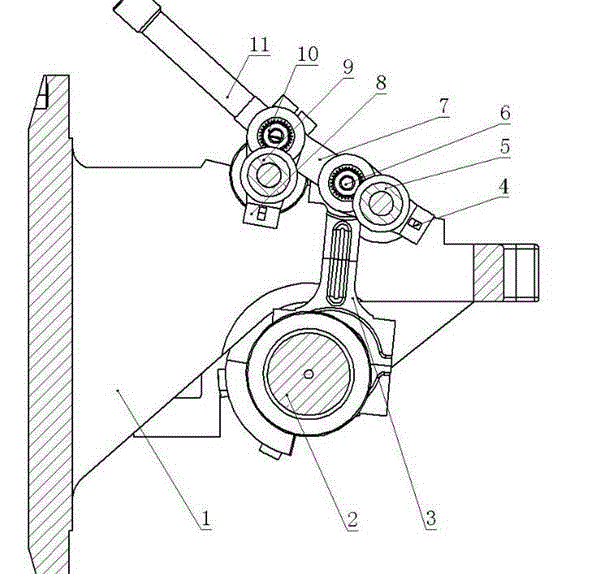

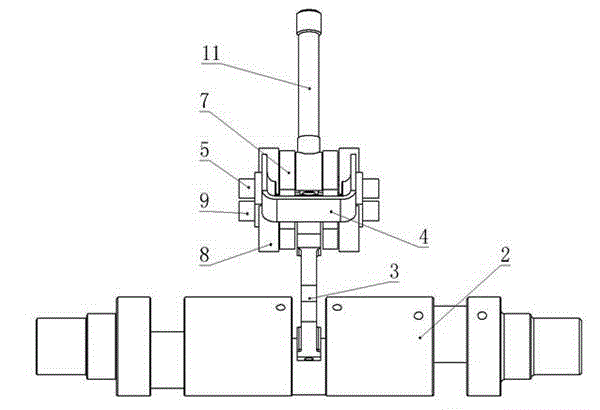

[0023] Such as figure 1 As shown, the single needle bed warp knitting machine needle bed crankshaft linkage mainly consists of a connecting rod frame 1, a crankshaft 2, several connecting rods 3, 4, 7, 8, 11, pin shafts 6, 10.

[0024] Several grooves are opened on the connecting rod frame 1, and the crankshaft 2 is fixed in the grooves and can rotate freely.

[0025] One end of the connecting rod a3 is connected to the crankshaft 2, and the other end penetrates the middle of the pin a6 and can rotate around it.

[0026] A clamping device is provided at the joint between the connecting rod a3 and the crankshaft 2, the contact surface between the clamping device and the crankshaft 2 is a circular arc concave surface, the clamping device is divided into two parts, each part is equipped with a bearing bush, There is a small hole on the bearing pad, and the separated two part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com