Anti-sloughing hole reverse circulation sampling bit

A sampling drill bit and reverse circulation technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling and mining, etc., can solve the problems of hindering the production efficiency of coal seam mining, restricting the development of productivity, and not being able to sample at fixed points, so as to improve the efficiency and safety of coal mine sampling , reduce gas disaster accidents, and save sampling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

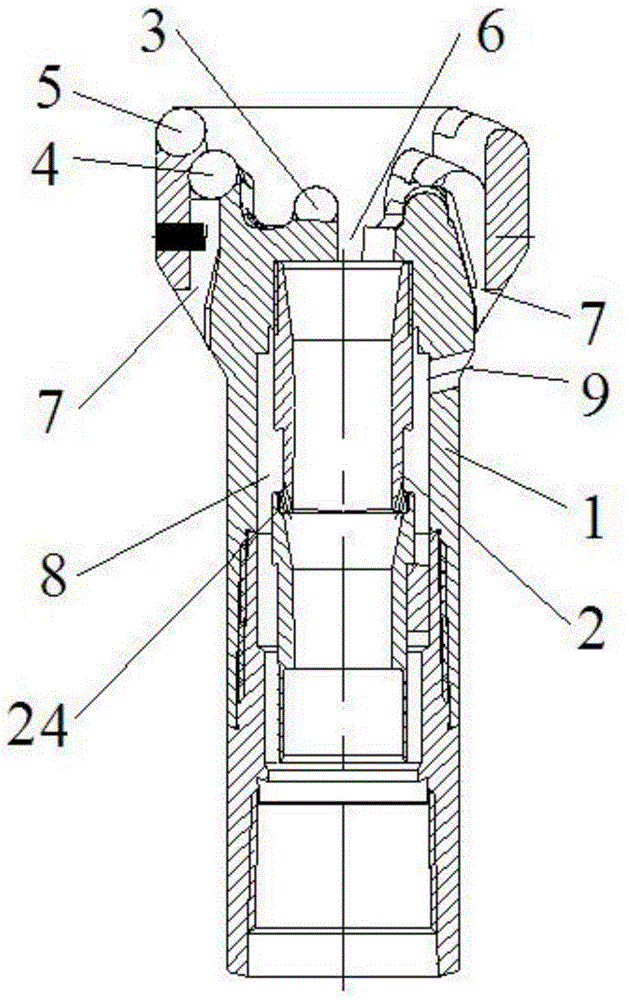

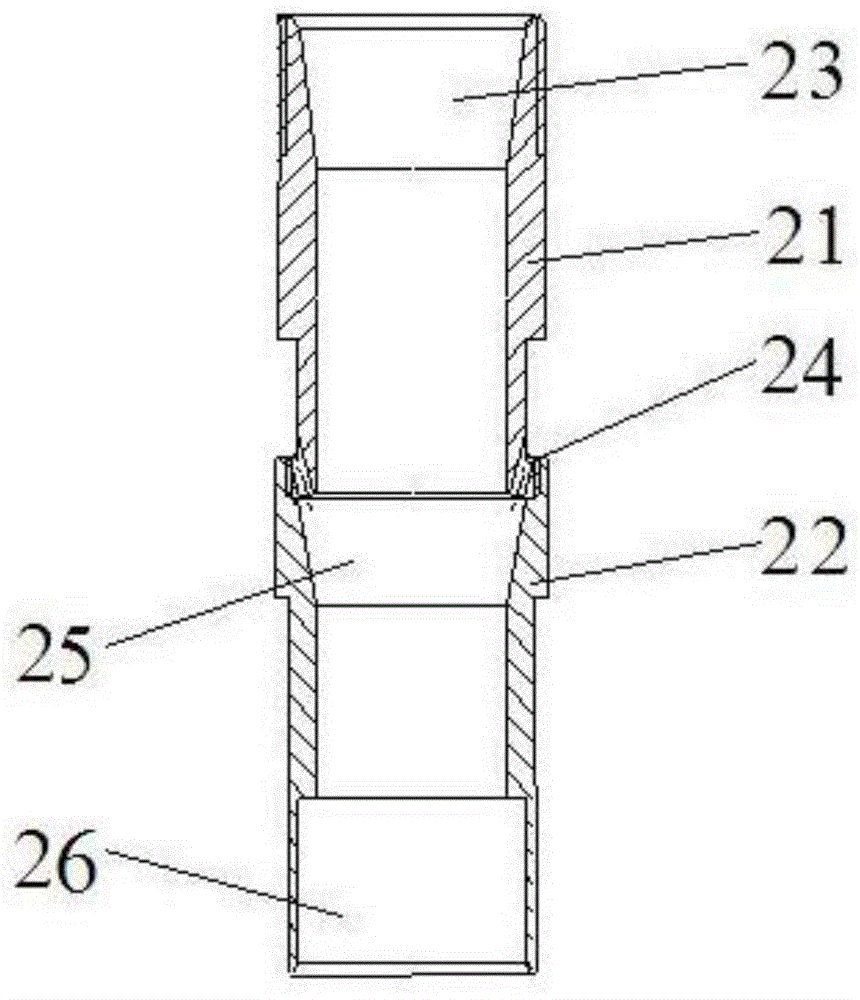

[0018] As shown in the figure, the anti-collapse hole reverse circulation sampling drill bit in this embodiment includes a drill body 1 with a cavity inside and a hollow annular injector 2 arranged in the drill body 1; To the outside, an inner layer 3, a middle layer 4 and an outer layer cutting head 5 are respectively provided. The inner layer cutting head 3 is provided with a sampling port 6, and the middle layer 4 and the outer layer cutting head 5 are provided with a The gap groove 7 of the slag, the annular injector 2 is fixedly arranged in the cavity of the drill bit body 1 and forms an annular inner cavity 8 with the inner wall of the drill bit body 1, and the sampling port 6 communicates with the hollow annular injector 2; The drill bit body 1 is correspondingly provided with an injection hole 9 , and the injection hole 9 communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com