Boiling type water cooling system for engine and engine

A water-cooling system and engine technology, which is applied to the cooling of the engine, engine components, machines/engines, etc., can solve the problems affecting the normal operation of the engine, affecting the arrangement of related engine components, and the power drop of the engine at the initial stage of starting, so as to improve the refrigeration efficiency. And heat dissipation efficiency, increase heat dissipation effect, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

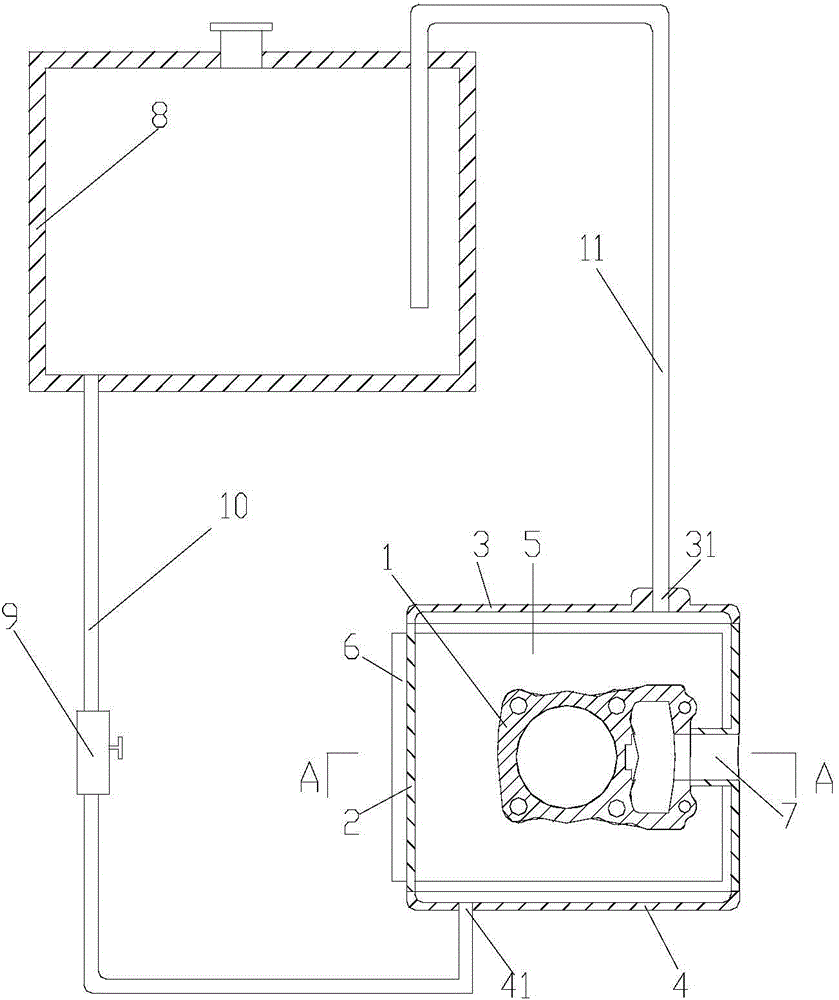

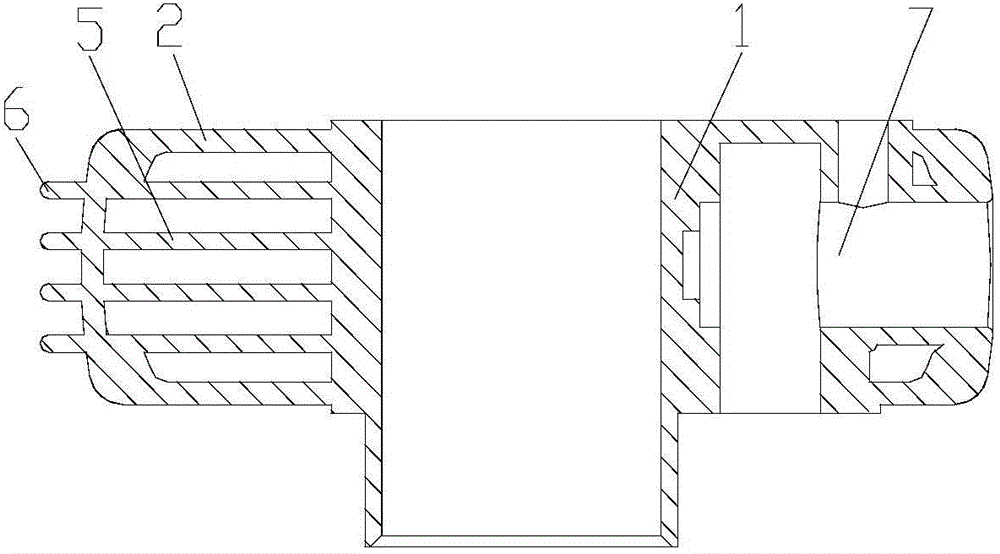

[0020] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 View along A direction, as shown in the figure: the engine boiling water cooling system of the present embodiment includes a water tank and a cooling water jacket located outside the engine block 1 and surrounding the engine block 1 (surrounding along the circumferential direction of the cylinder block), so The cooling water jacket includes a sleeve body 2 and an end cover sealedly connected with the sleeve body 2. The front and rear ends of the sleeve body are opened, and the end cover includes a front end cover 3 and a The rear end cover 4, the cooling water jacket is provided with a water inlet 41 and an exhaust port 31 communicating with the water tank; the front and rear of the present invention refer to the corresponding front and rear positions after the engine is installed on the vehicle, if it is not installed on the vehicle, it is The orientation is perpendicular t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com