Boiler internal structure with good combustion effect

A combustion effect and internal structure technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve problems such as the improvement of the furnace arch coverage grate area, and the inability to adjust the burning coal, so as to achieve simple structure, convenient production and processing, and maintenance easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

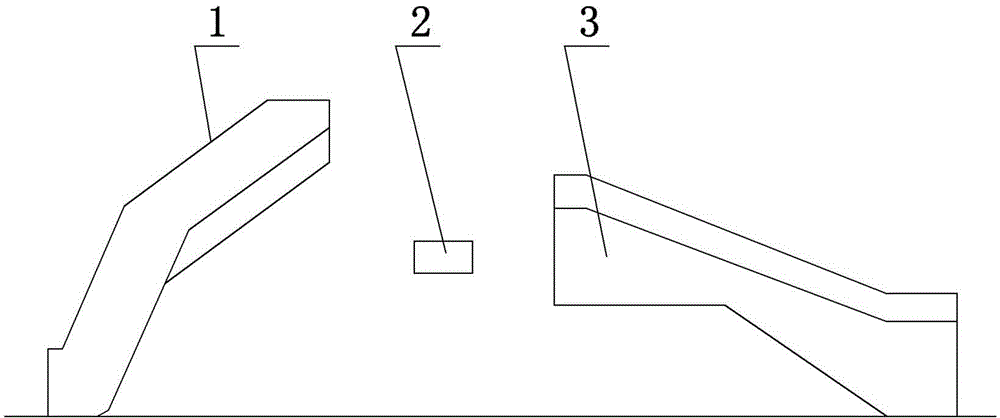

[0015] The present invention includes a front arch 1 and a rear arch 3, and is characterized in that a living arch 2 is movably arranged between the front arch 1 and the rear arch 3.

[0016] As a preferred solution of the present invention, the two ends of the living arch 2 are overlapped on the inner wall of the boiler.

[0017] As another preferred solution of the present invention, the living arch 2 is made of refractory materials.

[0018] The present invention has a simple structure, and only needs to set up a lapping platform in the existing boiler, and then add a living arch 2 to lap the living arch 2 inside the boiler by lapping, which has a simple structure and is convenient for production and processing.

[0019] The living arch 2 is made of refractory material, which can reduce the probability of damage to the living arch 2. The living arch 2 has a long service life and can greatly reduce the number of times of internal maintenance of the boiler.

[0020...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com