Construction method for crosswind multiphase flow system for high speed train test

A technology of high-speed trains and construction methods, which is applied in the direction of railway vehicle testing, etc., can solve the problems of low accuracy of simulated train high-speed operation parameters, difficult balance requirements for air volume and pressure, and reduce technical reference value, so as to improve accuracy and The effect of technical reference value, reducing artificial trimming, improving connection stability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

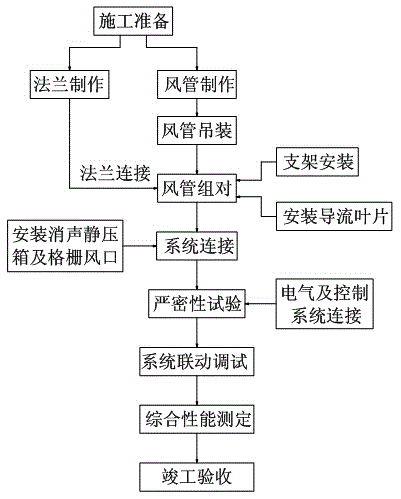

[0034] Such as figure 1 As shown, the present invention provides a construction method of a crosswind multiphase flow system for a high-speed train test, which is used for the construction and installation of a crosswind multiphase flow system for a high-speed train test. The construction process of the present invention mainly includes: construction preparation, manufacture of flanges and air ducts, hoisting of air ducts, butt welding of air duct groups and flange connection, installation and system connection of axial flow fans, silencing static pressure boxes and grille outlets , Electrical and control system installation, system linkage debugging and comprehensive performance measurement.

[0035] 1. Construction preparation

[0036] (1) System plan preparation

[0037] As described in Patent No. ZL 201220412622.1, the system to be constructed and installed in the present invention includes ten parallel-connected fans regulated by frequency converters and a sound-absorbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com