Test device and method for studying erosion damage under pipe bag dam joint breakage condition

A test device and tube-bag dam technology, which is applied to measuring devices, instruments, scientific instruments, etc., can solve problems such as dam core fill loss, dam body safety hazards, and short tube-bag length, so as to ensure the accuracy of records and save energy. The effect of low labor cost and processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

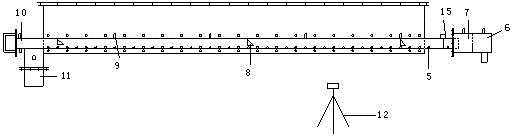

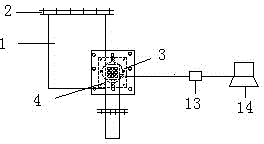

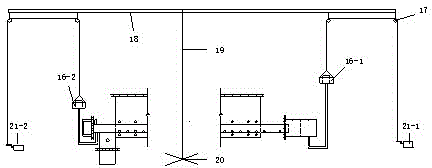

[0028] Such as figure 1 , 2 As shown, a test device for scour damage under the condition of pipe bag dam joint pipeline side wall damage, including pipe bag sand box 1, the cover plate 2 on the upper part of pipe bag sand box 1 and pipe bag sand box 1 are connected by bolts , the bolts are represented by short lines in the figure; the pipe bag side wall 4 is fixed between the pipe bag sand box 1 and the seam pipeline 3 through the screw rod and the embedded screw, and the pipe bag damage opening 8 is arranged on the pipe bag side wall 4; the seam The two ends of the pipeline 3 are respectively the pipeline input end 6 and the pipeline output end 10, and a sand material collection box 11 is provided near the pipeline output end 10, and the pipeline input end 6 is connected to the seam pipeline through the steady flow chamber 7. 3 connection, the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com