Method for obtaining monocrystalline silicon holocrystalline face etching rate under action of surface active agents

A surfactant and etching rate technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as large errors, high technical requirements, and inability to explain the real reasons for silicon etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Example 1 is used to illustrate the detailed implementation steps of the present invention and the results obtained; Example 2 is used to illustrate that the present invention has wide applicability to etching systems under the action of different surfactants; Example 3 is used to illustrate surface activity Implementation effect of three-dimensional microstructure simulation of single crystal silicon under the action of agent.

[0068] The design variables in all examples are: Nine parameters of the Monte Carlo S-AEP etch probability function: ε 11 ,ε 12 ,ε 21 ,ε 22 ,E 1 ,E 2 ,g,E m ,r 0 .

[0069] Example 1 (determination of the etching rate of any {h, k, l} crystal plane under the etching conditions of 80°C KOH+IPA):

[0070] Etching environment: 80°C, KOH (medium concentration) + IPA.

[0071] Etching object: single crystal silicon

[0072] Experimental data: 80 ℃, KOH (medium concentration) and KOH (medium concentration) + IPA etching conditions seven con...

Embodiment 2

[0185] Example 2 (25wt%TMAH+0.1%(vv)Triton, the etching rate of any {h k l} crystal plane is determined under the process condition of 80°C):

[0186] Etching environment: 25wt%TMAH+0.1%(vv)Triton, 80°C

[0187] Etching object: single crystal silicon

[0188] Experimental data: Under the etching conditions of 25wt% TMAH at 80°C and 25wt% TMAH+0.1% (vv) Triton at 80°C, the experimental etching rates of seven constrained crystal planes.

[0189] Experimental goal: Under the action of surfactant, single crystal silicon wet etching a small amount of crystal facets to obtain the etching rate of the whole crystal facets

[0190] Seven constrained crystal planes: (100), (110), (111), (331), (211), (411), (310)

[0191] The experimental etching rate (um / min) of the seven constrained crystal planes at 80°C and 25wt% TMAH:

[0192] V(100)=0.437

[0193] V(110)=0.698

[0194] V(111)=0.031

[0195] V(331)=0.919

[0196] V(211)=0.784

[0197] V(411)=0.870

[0198] V(310)=0.922

...

Embodiment 3

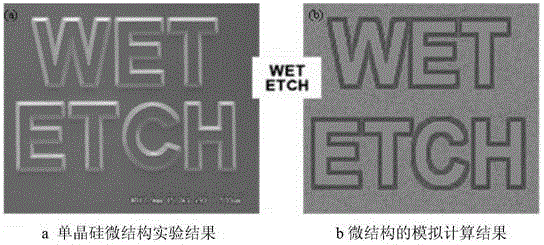

[0208] Example 3 (Calculation and simulation of three-dimensional microstructure processing of single crystal silicon under the action of surfactant)

[0209] Etching environment: 25%TMAH+0.1%(vv)Triton, 80℃;

[0210] Etching object: single crystal silicon

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com