Ion injection machine internal beam detection system

A technology of ion implanter and detection system, which is applied in discharge tubes, electrical components, circuits, etc., to achieve the effects of simple system, easy assembly and production, and high collection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further introduced below in conjunction with the specific embodiments of the accompanying drawings. These descriptions are all illustrative, and the present invention is not limited thereto. The scope of the present invention is limited only by the scope of the appended claims.

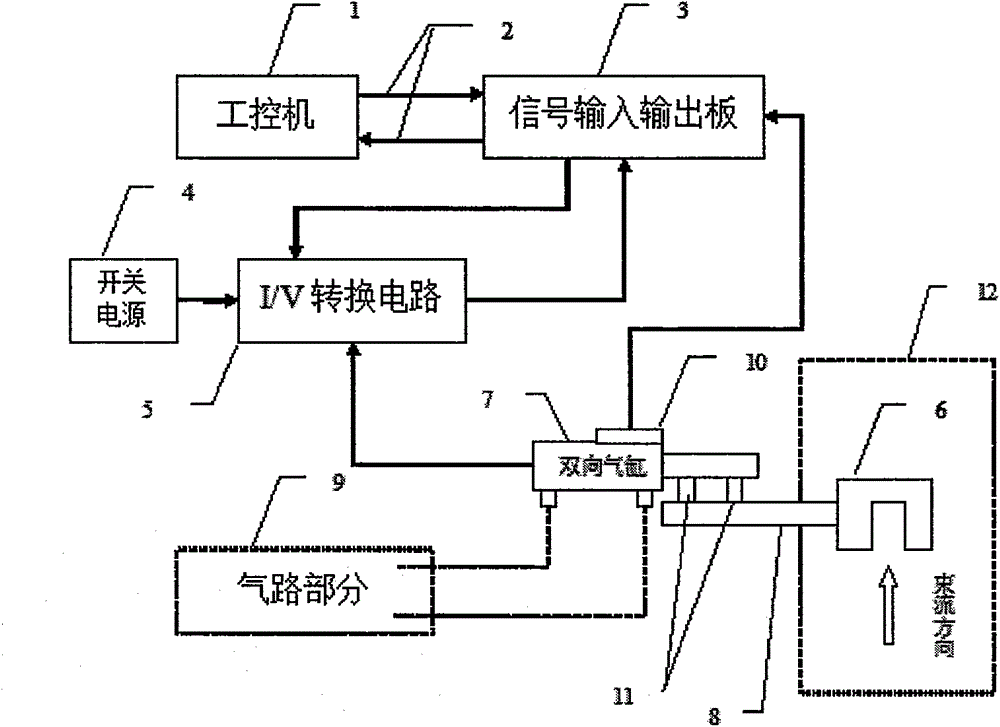

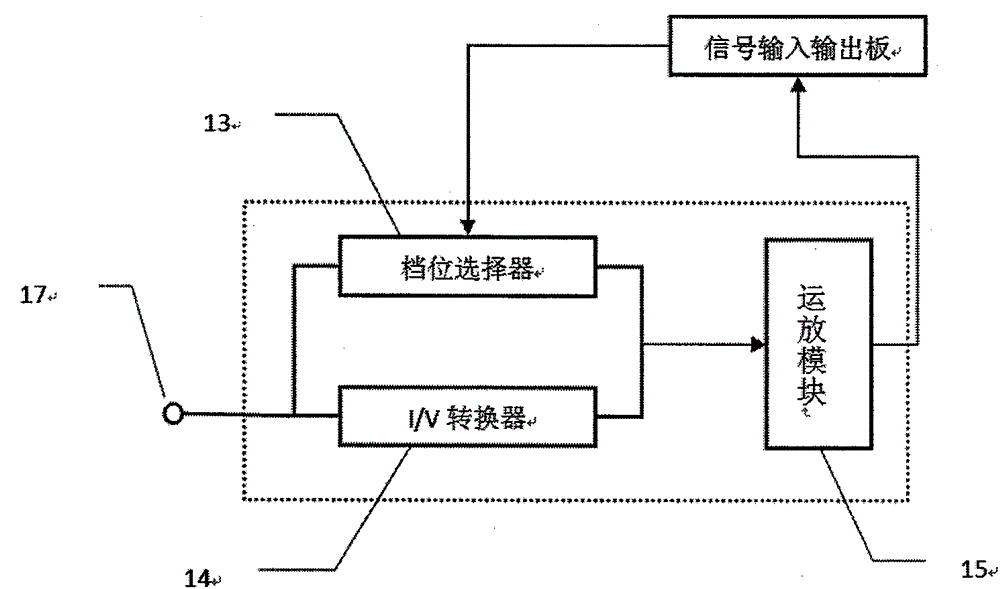

[0017] see figure 1 A beam current detection system in an ion implanter, comprising: an industrial computer (1), an optical fiber (2), a signal input and output board (3), a switching power supply (4), an I / V conversion circuit (5), and a Faraday cup ( 6), two-way cylinder (7), transmission bearing (8), air circuit part (9), in-position switch (10), fixed support frame (11), wherein the I / V conversion circuit consists of gear selector (13), It consists of an I / V converter (14) and an operational amplifier module (15).

[0018] The industrial computer (1) is connected to the signal input and output board (3) through the optical fiber (2) to send and receive data i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com