A car key battery assembly

A car key and battery assembly technology, which is applied to battery pack components, battery boxes/coats, portable system fuel cells, etc., can solve problems such as poor conductivity, short service life, oxidation of shrapnel and battery contact points, etc., to achieve electrical conductivity High performance, long life, good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

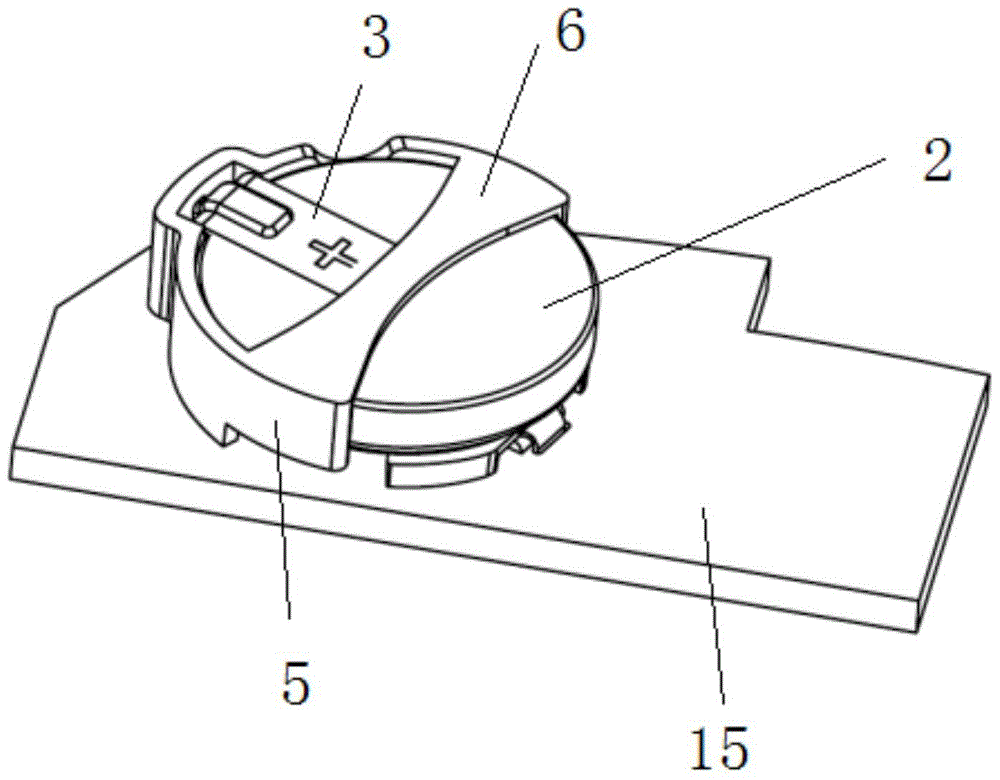

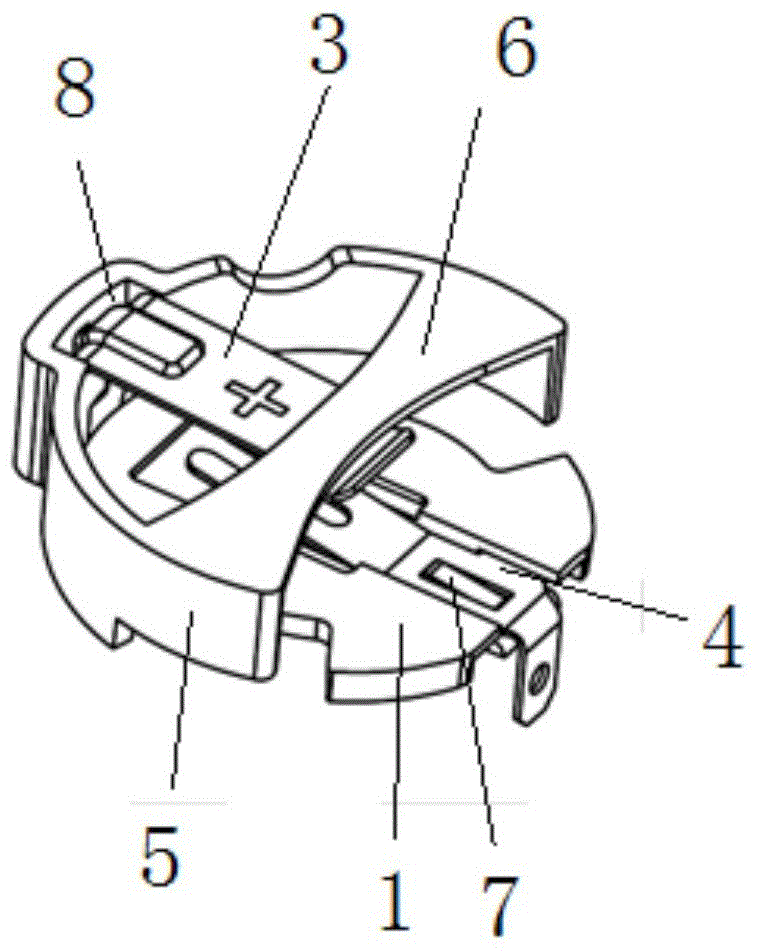

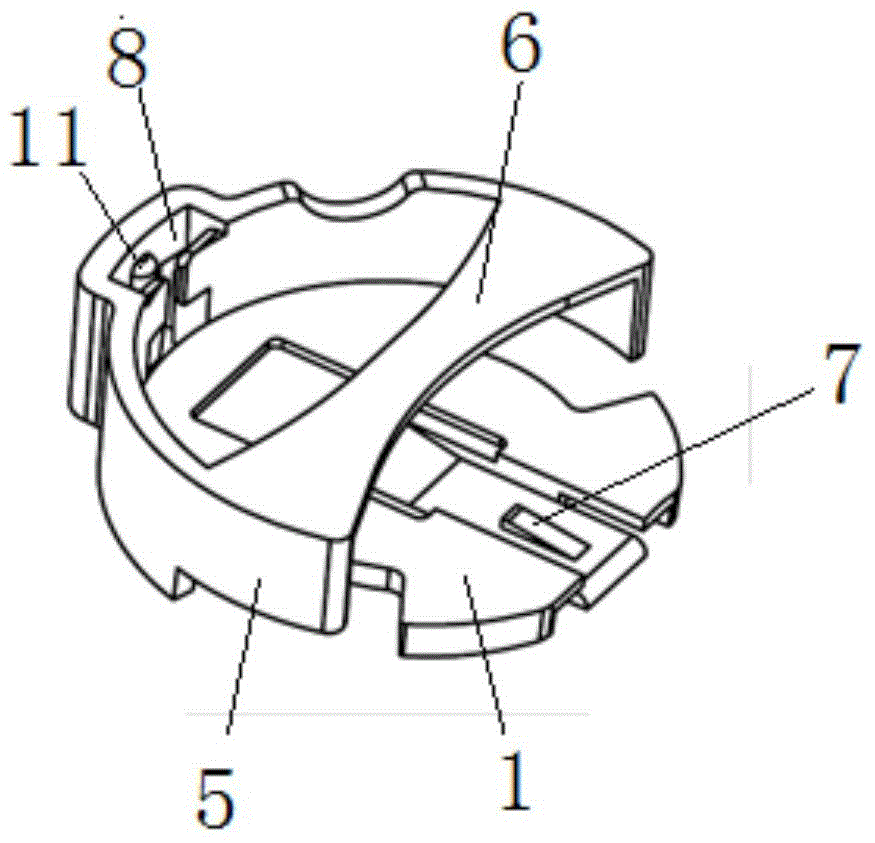

[0021] like Figure 1 to Figure 7 The shown car key battery assembly includes a battery fixing shell. The car key battery structure also includes a metal dome and a battery 2. The metal dome includes a positive electrode piece 3 and a negative electrode piece 4. The battery fixing shell includes a bottom plate 1, along the bottom plate 1 The arc-shaped side wall 5 provided on the edge, the two ends of the upper end edge of the arc-shaped side wall 5 are connected by the limit arm 6, the bottom plate 1, the arc-shaped side wall 5, and the limit arm 6 form the battery for the battery 2 to be put in Slot structure, the upper end surface of the bottom plate 1 is provided with a concave surface, the concave surface is provided with a limit bump 7, the negative plate 4 is provided with a limit slot 10 sleeved on the limit bump 7, and the limit bump 7 The snapping structure is formed by being snapped into the limiting slot 10 . One end of the negative electrode sheet 4 is the batter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com