Film-type two-way hydraulic vibration near-resonance type double-drum vibrating mill

A two-way hydraulic and hydraulic exciter technology, applied in grain processing and other directions, can solve the problems of high vibration intensity, reduced reliability, and low service life of the mill, and achieve uniform distribution of vibration force, small vibration interference, and simple manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

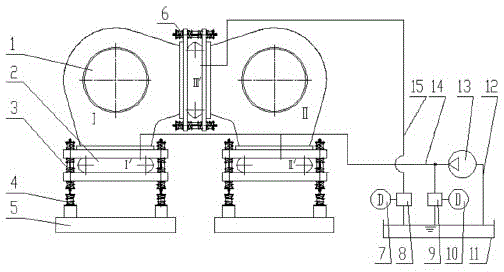

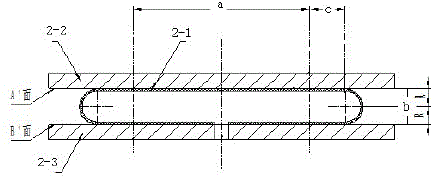

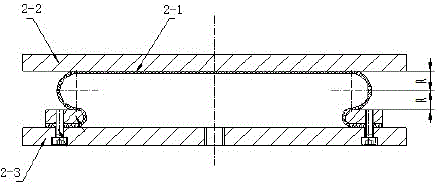

[0031] The general-purpose mechanical exciter is replaced by a thin-film hydraulic exciter, which is composed of a cylinder body 1, a thin-film hydraulic exciter 2, a near-resonance spring group 3, a base 5, and a hydraulic device. figure 1 As shown, the cylinder 1 includes a left cylinder and a right cylinder, the left cylinder and the right cylinder are arranged in sequence in the horizontal direction, the left cylinder and the base 5 are arranged in sequence in the vertical direction, and the right cylinder and the base 5 are arranged in the vertical direction The directions are arranged in sequence, and a thin-film hydraulic vibrator 3 is installed between the left cylinder and the right cylinder, between the left cylinder and the base 5, and between the right cylinder and the base 5; each exciter has at least one near-resonance spring Gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com