Garbage landfill site multi-layer leachate recirculation pipe network and gas-liquid drainage exchange system

A landfill and exchange system technology, applied in the field of urban waste treatment, to achieve the effects of smooth exhaust and drainage, water saving, and environmental pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

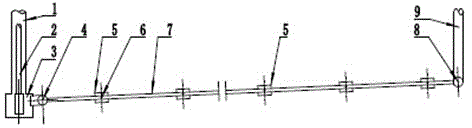

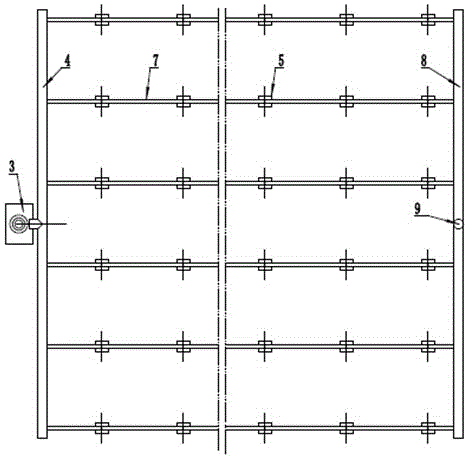

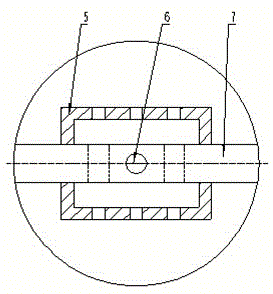

[0033] After the landfill site is leveled, the first layer of leachate pipe network is laid out at the bottom according to the design plan. The distance between each pipe is 4 meters, the pipe diameter is 60, and the slope is 3%. At the high end, a large pipe with a pipe diameter of 100 is used. Each pipeline is connected, and a gas-liquid adding pipe is set at the same time. At the lower end, use a pipe with a diameter of 100 to connect each pipe, and connect a leachate storage tank at the same time, and set a pump pipe on the leachate tank. Then, loosely fill the 3m-high mineralized waste first, and then pile up new waste. When the height of the garbage pile reaches 2m, start laying the second layer of leachate pipe network. The structure of the pipe network is the same as that of the first layer. After the pipe network is set up, the garbage is piled up. When the height of the garbage pile reaches 4m, the third layer of leachate pipe network will be laid out. The structure...

Embodiment 2

[0038] The new waste landfill site is selected next to the waste dump, and the existing waste dump is used as a leachate filter. The leachate pipe network layout and construction procedures of the new landfill are the same as in Example 1. The collected high-concentration ammonium nitrogen leachate is transported to the waste landfill, and the original pipe network is used for leachate recharge, so that the effect of removing ammonium nitrogen is better. Then transport the collected low-concentration ammonium nitrogen leachate back to the new landfill, and use the pipe network of the new landfill to recharge the leachate to accelerate the aerobic degradation process of the new landfill and improve the degradation efficiency . Reduce environmental pollution and save the cost of high-concentration ammonium nitrogen leachate treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com