Device for punching valve casing seal chamfer

A technology of impact processing and impact body, applied in the direction of engine components, mechanical equipment, etc., can solve the problems of difficult control of manual percussion force, different action stroke length, unstable chamfer size, etc., and achieve novel structure and precise processing position , solve the effect of smoking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

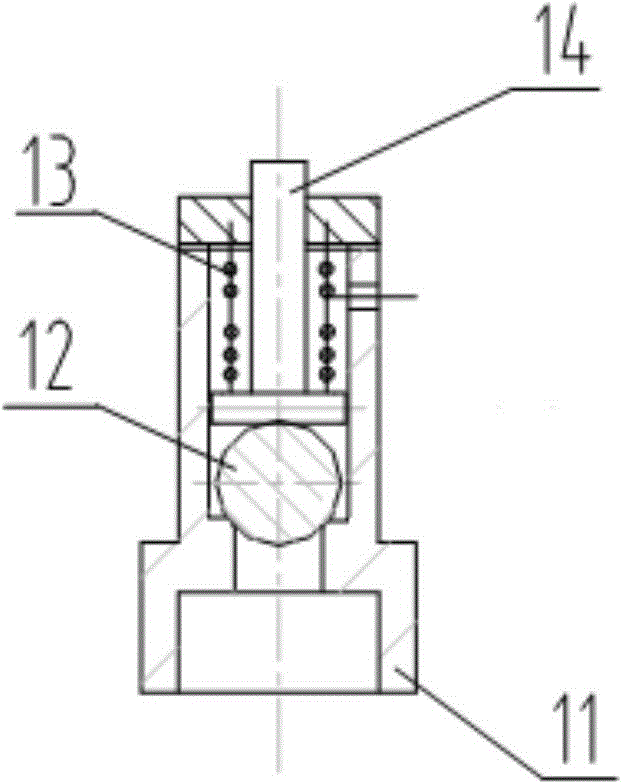

[0028] see figure 1 The valve nozzle of the turbine power generation device includes a valve housing 11, a steel ball 12, a return spring 13 and a valve ejector rod 14. It can be seen from the figure that the closed state of the ball socket at the junction of the sealing steel ball 12 and the valve housing 11 affects its sealing performance.

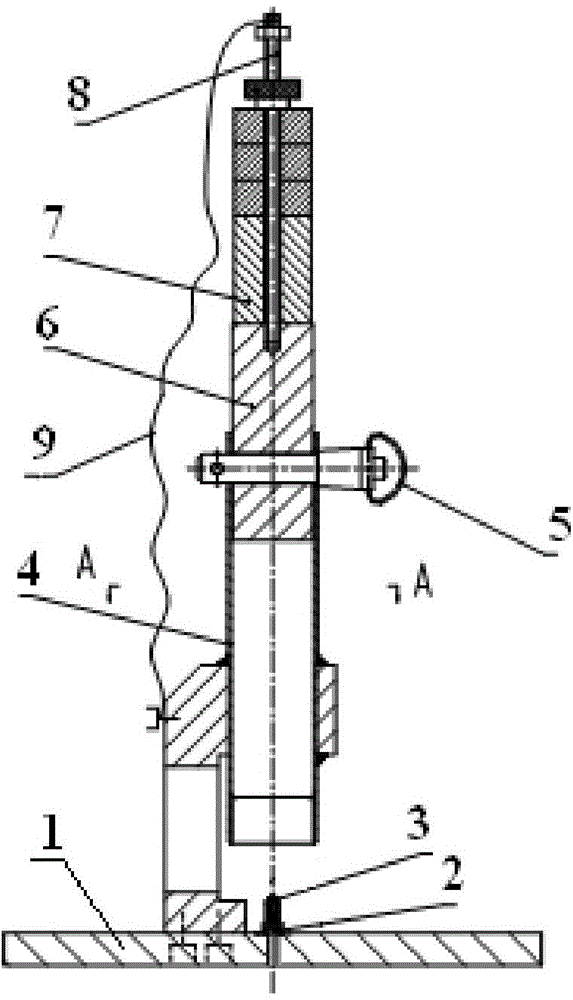

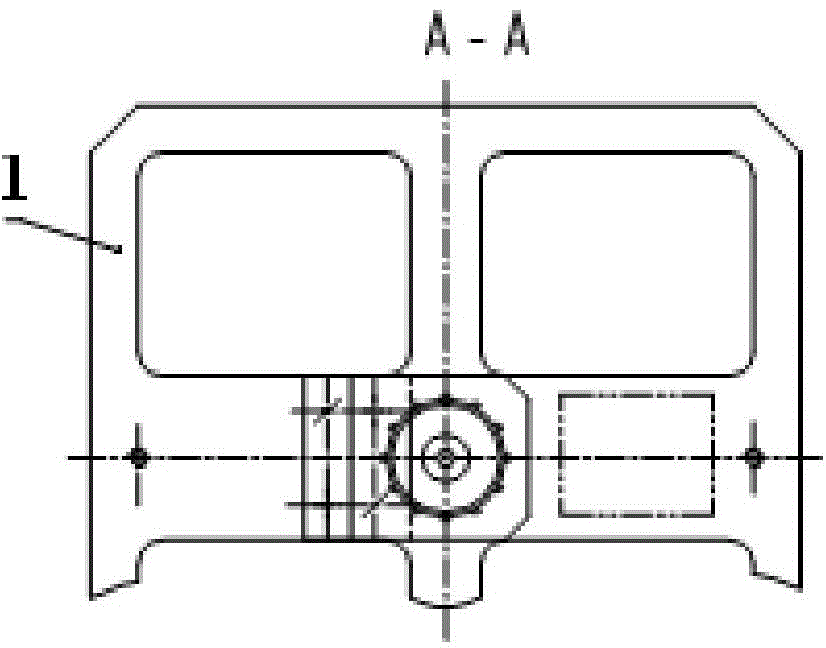

[0029] see Figures 2 to 4 , the present invention includes a base 1, a positioning pin 2, a valve ejector rod simulation part 3, a travel bracket 4, a limit operation pin 5, a movable impact body 6, a counterweight 7, a screw nut assembly 8, a steel ball 12 and a traction rope 9; The base 1 plays a stabilizing role in the process of processing. The force-bearing surface of the impact operation is borne by the circular step surface of the base 1, which is located at the support surface of the positioning pin 2, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com