An on-site storage device for wet-mixed mortar

A technology of wet-mixed mortar and storage device, which is applied in the direction of unloading device, clay preparation device, mixing operation control device, etc., can solve the problems of unstable quality of wet-mixed mortar, energy waste, dust on construction site, etc., and achieve weighing effect. Better precision, better flipping effect, better sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

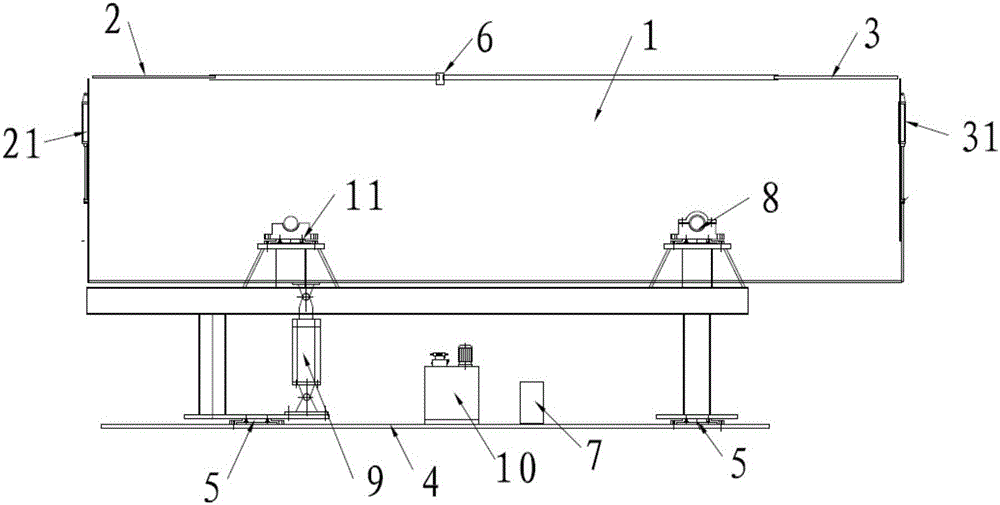

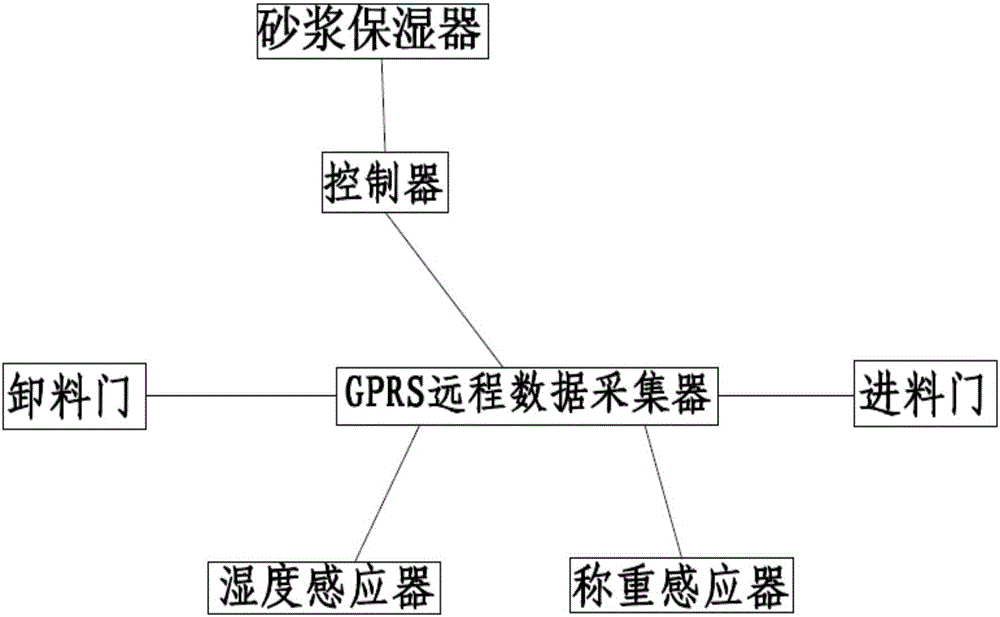

[0042] Embodiment two: if figure 1 with figure 2 As shown, the present invention is also provided with a GPRS remote data acquisition system and controller, and the GPRS remote data acquisition system is respectively connected with load cell 5, humidity sensor 6, feed door 2 and discharge door 3, and can collect weighing The sensing data of the heavy sensor 5 and the humidity sensor 6 and the collection of the working time and times of the feeding door 2 and the discharging door 3, so that the storage capacity, humidity parameters, storage time and use of the wet-mixed mortar in the cylinder 1 can be understood frequency. The controller is respectively connected with the wet-mixed mortar humidifier 7, the lifting assembly 9, the feed door cylinder 21 and the discharge door cylinder 31 to control their work, so remote operation can be realized, the operation is very convenient, and it can be remotely operated according to GPRS. The data collected by the data acquisition syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com