Rapid material hoister used for large-scale construction

A hoist and material technology, applied in elevators, elevators in buildings, transportation and packaging, etc., can solve the problems of unstable operation, high power consumption, lack of efficiency and safety, etc., to reduce energy consumption, consumption Low energy and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

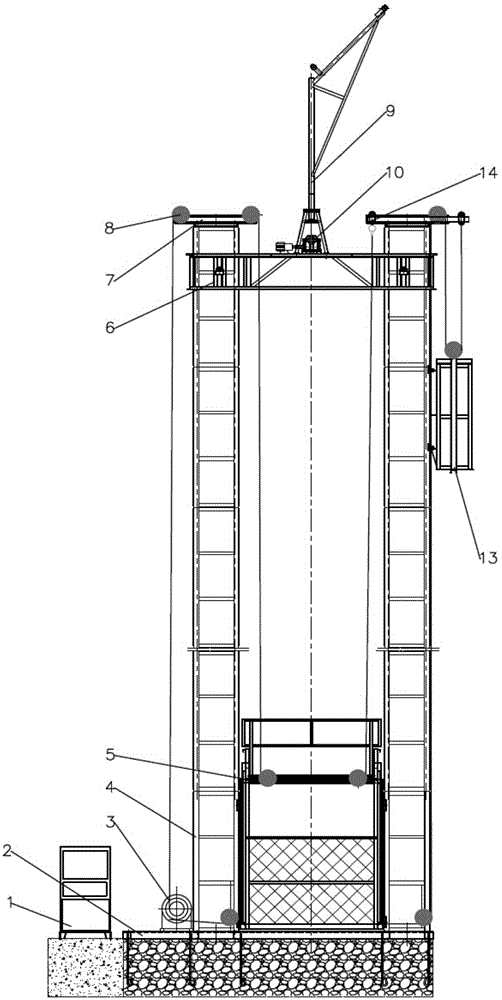

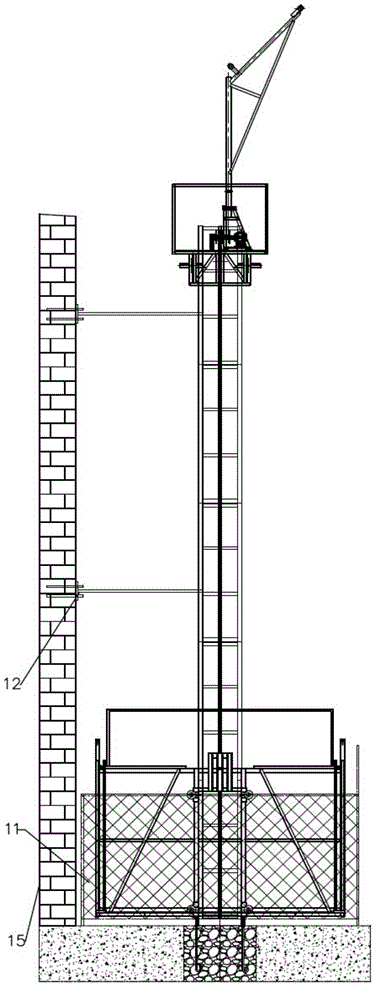

[0021] Through the following examples, combined with the attached Figure 1-6 , the technical solution of the present invention will be further specifically described.

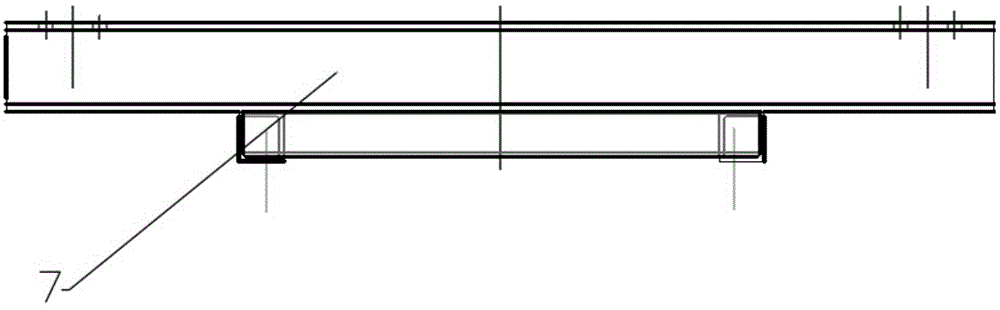

[0022] A rapid material hoist for large-scale construction, including a base 2, an electrical system 1, and a support beam 15 vertically fixed to the base 2, the height of the support beam 15 is 30 meters, and the base 2 is provided with two vertically fixed guide rails frame 4, the top of the guide rail frame 4 is provided with a sky beam frame 7, and a hanging cage part 5 is arranged between the left and right rail frames 4, and the hanging cage part 5 is connected with the sky beam frame 7 through a steel wire rope and a pulley 8, wherein The top pulley 8 of the frame 7 is provided with a lifting weight limiter 14 on one side connected to the cage part 5, and the other side is connected to the counterweight box 13 through a steel wire rope, and the top pulley 8 of the left sky beam frame 7 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com