Oil-saving combustion-supporting core and preparation method thereof

A plastic and rare metal technology, applied in the field of fuel-saving combustion-supporting core and its preparation, can solve the problems of affecting the smooth passage of fuel, indispensable fuel use, and excessive exhaust emissions, achieving excellent shrinkage performance, saving fuel, and improving the performance of oil products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

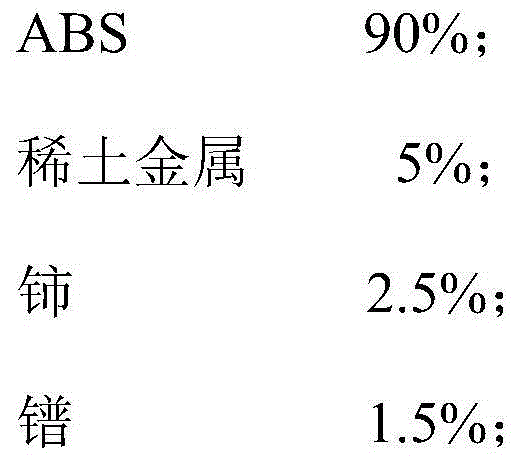

[0025] A fuel-saving combustion-supporting core, comprising the following components in weight percentage:

[0026] PP 95%;

[0027] Scandium 5%.

Embodiment 2

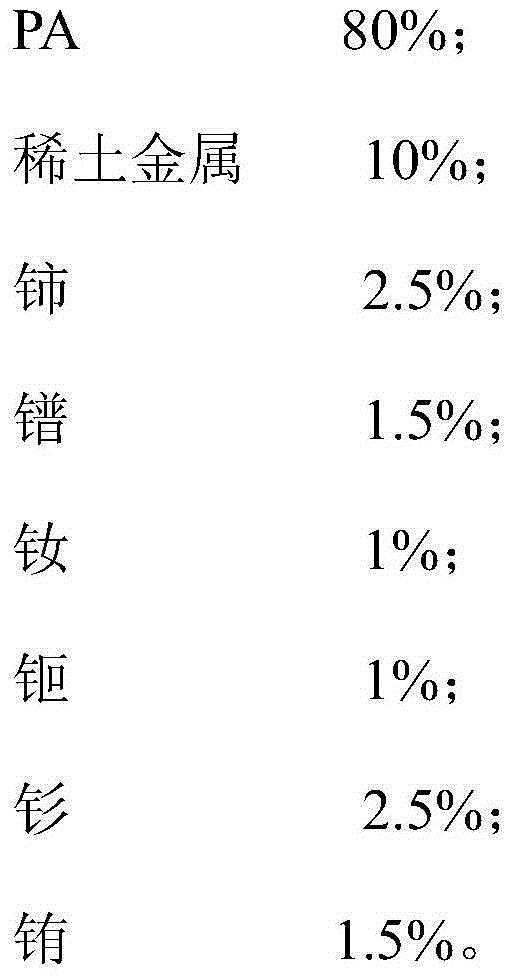

[0029] A fuel-saving combustion-supporting core, comprising the following components in weight percentage:

[0030] PE 20%;

[0031] Yttrium 80%.

Embodiment 3

[0033] A fuel-saving combustion-supporting core, comprising the following components in weight percentage:

[0034] PVC 90%;

[0035] Lanthanum 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com