Ultrathin PI cover film and preparation method thereof

A cover film, ultra-thin technology, applied in chemical instruments and methods, film/sheet adhesives, printed circuit manufacturing, etc., can solve the problems of high cost, high difficulty, low yield, etc., to improve operation Improve performance and production efficiency, improve static bending resistance, and meet performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of preparation method of ultra-thin PI covering film, comprises the steps:

[0022] (1) Configure the above-mentioned polyimide acid prepolymer (PAA) solution, coat the above-mentioned polyimide acid prepolymer (PAA) solution of one deck on the 18 μm oil-free aluminum foil of Chinalco, control coating The drying thickness is 3 μm, after drying in a continuous oven at 120°C-150°C-160°C, and then imidizing in a continuous high-temperature oven at 180-360°C, an ultra-thin PI film is formed;

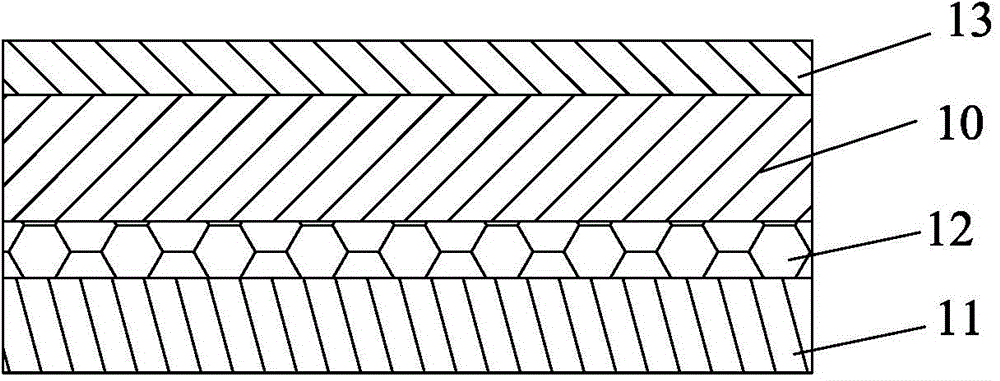

[0023] (2) The ultra-thin PI film will be corona coated on one side of the special glue SF305C of Guangdong Shengyi Technology Co., Ltd. for the cover film, and the drying thickness of the coating is controlled to be 10 μm. - 75W release paper lamination, get ultra-thin PI cover film.

[0024] Use the ultra-thin PI cover film and the etched copper-clad laminate for rapid pressing, the rapid pressing conditions are 100MPa, 180°C, 120 seconds, and then cured at 170°C for 1 hour,...

Embodiment 2

[0026] A kind of preparation method of ultra-thin PI covering film, comprises the steps:

[0027] (1) configure the above-mentioned polyimide acid prepolymer (PAA) solution, coat the above-mentioned polyimide acid prepolymer (PAA) solution of one deck on the 25 μm oil-free aluminum foil of Chinalco, control coating The drying thickness is 5 μm, after being dried in a continuous oven at 120°C-150°C-160°C, and then imidized in a continuous high-temperature oven at 180-360°C, an ultra-thin PI film is formed;

[0028] (2) Corona the ultra-thin PI film, and coat the special glue SF305C for the cover film of Guangdong Shengyi Technology Co., Ltd. on one side, control the dry thickness of the coating to 15 μm, and compound it with the release paper after drying , to obtain ultra-thin PI cover film.

[0029] Use the ultra-thin PI cover film and the etched copper-clad laminate for rapid pressing, the rapid pressing conditions are 100MPa, 180°C, 120 seconds, and then cured at 170°C for...

Embodiment 3

[0031] A kind of preparation method of ultra-thin PI covering film, comprises the steps:

[0032] (1) configure the above-mentioned polyimide acid prepolymer (PAA) solution, coat the above-mentioned polyimide acid prepolymer (PAA) solution of one deck on the 35 μm oil-free aluminum foil of Chinalco, control coating The drying thickness is 8 μm, after drying in a continuous oven at 120°C-150°C-160°C, and then imidizing in a continuous high-temperature oven at 180-360°C, an ultra-thin PI film is formed;

[0033] (2) Corona the ultra-thin PI film, and coat the special glue SF305C for the cover film of Guangdong Shengyi Technology Co., Ltd. on one side, control the dry thickness of the coating to 15 μm, and compound it with the release paper after drying , to obtain ultra-thin PI cover film.

[0034] Use the ultra-thin PI cover film and etched copper-clad board for quick pressing, the quick pressing conditions are 100MPa, 180°C, 120 seconds, and then cured at 170°C for 1 hour, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com