Nylon coating trademark cloth for bar code printing and preparation method

A nylon coating, barcode printing technology, used in dry cleaning fiber products, textile material processing, textile and other directions, can solve problems such as unsatisfactory structural stability and poor printing effect, achieve good printing effect, improve printing effect, barcode printed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

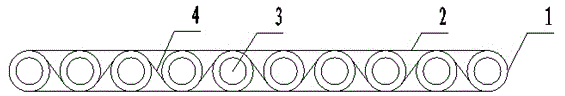

[0024] Example. Nylon coated trademark cloth that can be used for barcode printing, including nylon base cloth 1, the surface of nylon base cloth 1 is provided with polymer coating 2; nylon base cloth 1 includes warp yarn 3 and weft yarn perpendicular to warp yarn 3 Thread 4, the warp density of the nylon base fabric 1 is 75 threads / cm-80 threads / cm, the weft density of the nylon base fabric 1 is 35 threads / cm-50 threads / cm; the warp yarn 3 is a monofilament of 30D or 70D , The weft yarn 4 is a 70D polyester-nylon composite yarn.

[0025] The polymer coating 2 comprises the following components by weight:

[0026] Methanol, 2350-2400 parts; Calcium chloride dihydrate, 740-760 parts;

[0027] Nylon, 640-660 parts; Calcium carbonate, 490-510 parts;

[0028] Fluorescent whitening agent, 0.6-1 part; Span, 0.05-0.07 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com