A new oil and gas downhole friction and drag reduction device

A technology for reducing friction and drag and natural gas, which is applied in drilling equipment, directional drilling, earth-moving drilling, etc., can solve problems such as insignificant effect of reducing friction and drag in extended-reach wells, complex structure, and difficulty in ensuring stable operation of tools, etc. The effect of reducing friction and drag is obvious, the device structure is simple, and the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

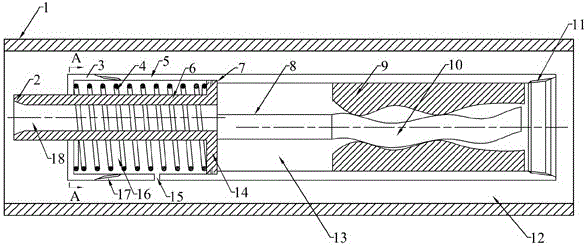

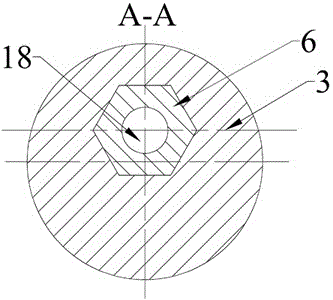

[0014] according to figure 1 As shown, a novel oil and gas downhole anti-friction and resistance reduction device proposed by the present invention is characterized in that it mainly includes: a first joint 2, a second joint 3, a spring 4, an outer layer pipe 5, a hexagonal kelly 6, Axial shoulder 7, cycloid shaft 8, third joint 11, first annular space 12, first chamber 13, eccentric shoulder 14, constant pressure channel 15, second chamber 16, fourth joint 17 and second Annulus 18. Wherein, the six kelly 6 includes a first joint 2 and an eccentric shoulder 14, the first joint 2 is used to connect the lower drilling tool, and the eccentric shoulder 14 is used to form a second chamber 16 with the outer tube 5 and the second joint 3 , the hexagonal kelly 6 and the second joint 3 transmit the torque during the drilling process through clearance fit, the eccentric shoulder 14 of the hexagonal kelly 6 and the inner wall of the outer tube 5 are dynamic seals, the hexkelly 6 can Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com